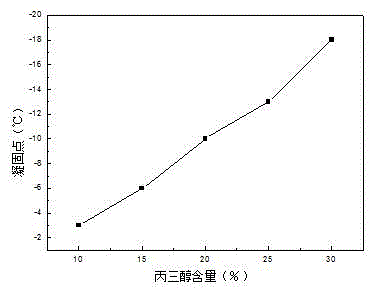

Low-solidifying-point foaming agent for oilfield operation

A technology of low freezing point and foaming agent, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as high freezing point, decreased fluidity, pollution, etc., and achieve good foaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

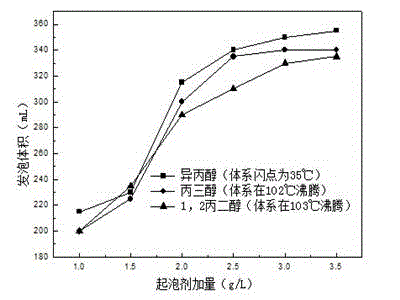

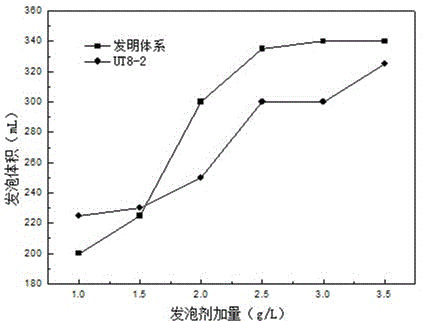

Method used

Image

Examples

Embodiment

[0017] The foaming performance of the foaming agent was evaluated, and the evaluation standard was carried out in accordance with the enterprise standard "QSH1020_1970-2008" of the Sinopec Shengli Oilfield Petroleum Administration Bureau. Accurately weigh 1.50g of the foaming agent sample, and weigh 498.50g of the Shengli brine in 1000mL In the beaker, stir slowly at a constant speed, the concentration of the obtained solution is 0.3%, and use the obtained solution to carry out indoor experiments according to the enterprise standards of the Sinopec Shengli Oilfield Petroleum Administration Bureau. The results show that its various indicators have reached the quality standards required by the industry. Its foaming volume reaches 340ml, and its half-life reaches 120min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com