Automatic stopping device of cotton strip release cylinder of cotton spinning drawing frame

A technology of automatic stop device and drawing frame, applied in textiles and papermaking, etc., can solve the problems of reducing the output rate of finished products of enterprises, failure to cut sliver in time, unsafe hidden dangers, etc., to achieve reasonable structure, eliminate fire hazards, prevent The effect of producing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The sliver take-off automatic stop device of the cotton yarn drawing frame of the present invention will be further described in detail below in conjunction with the accompanying drawings.

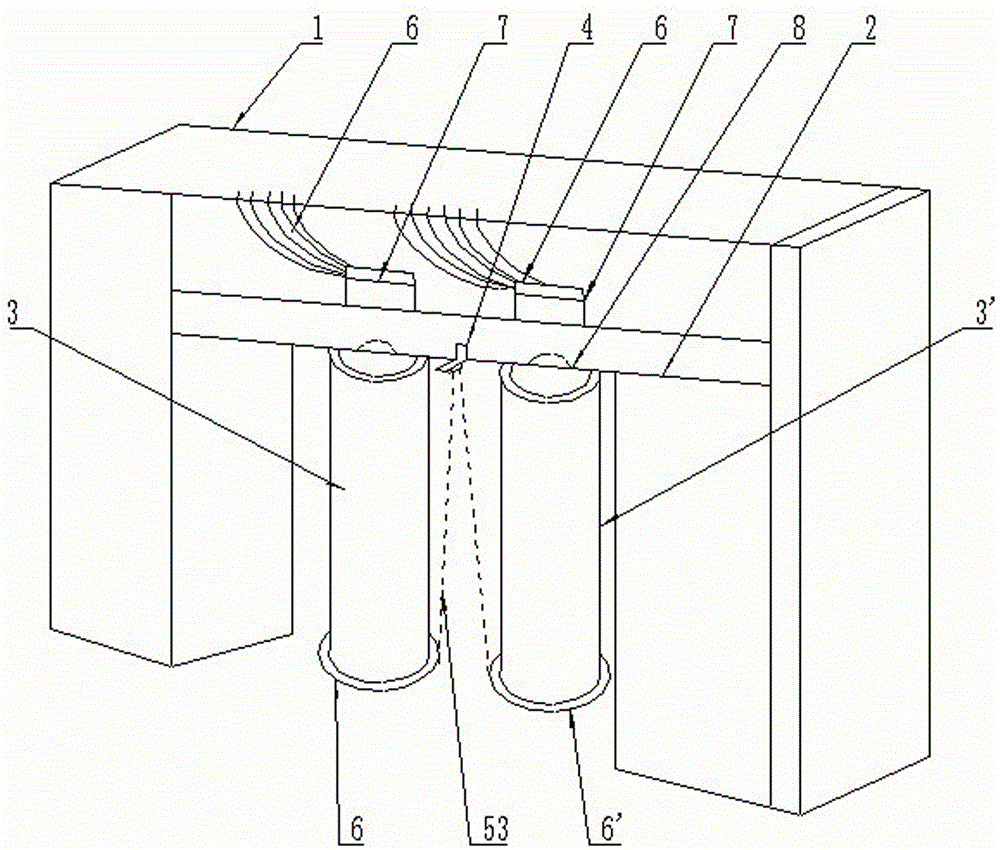

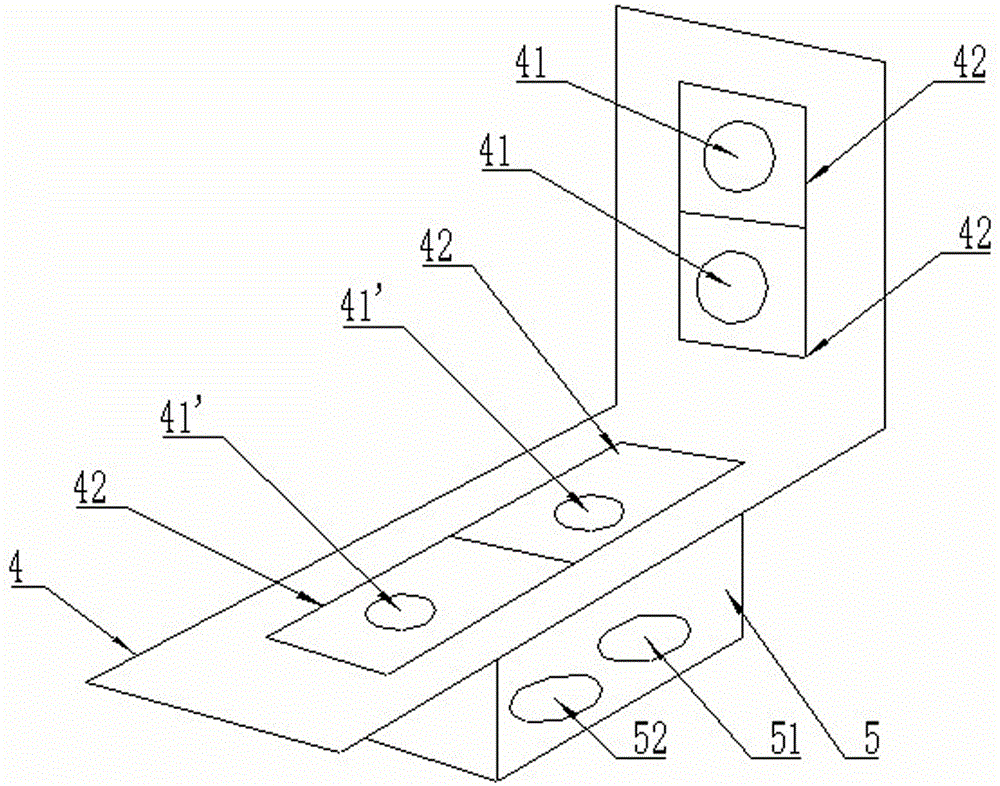

[0014] Depend on figure 1 , figure 2 It can be seen that the sliver take-off automatic stop device of the cotton spinning draw frame of the present invention includes a draw frame frame 1 and a draw frame back beam 2, and sliver cans 3, 3 are arranged under the side of the draw frame back beam 2 '; The back beam 2 of the draw frame is provided with an L-shaped bracket 4, the L-shaped bracket 4 is fixed on the back beam 2 of the draw frame by the first adjusting bolt 41, and several rectangular grooves 42 are arranged on the L-shaped bracket 4, The bottom of the L-shaped support 4 is provided with a reflective photoelectric relay 5, and the reflective photoelectric relay 5 is movable under the L-shaped support 4 through the second adjustment bolt 41'; the reflective photoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com