Jacquard electromagnet assembly with two injection moulding structure and manufacturing method of jacquard electromagnet assembly

A technology of injection molding and magnet assembly, which is used in jacquard machines, textiles, papermaking, textiles, etc., can solve problems such as affecting the coordination of electromagnets and iron hooks, short service life of electromagnets, affecting the operation of jacquard machines, etc., to improve the service life. , The effect of increasing the end face area and avoiding the phenomenon of magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

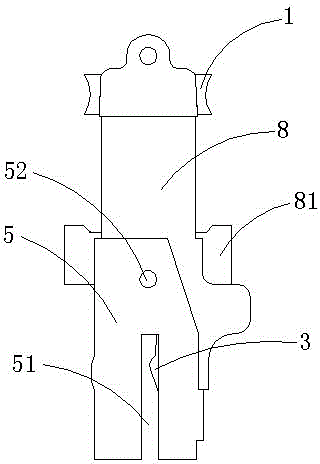

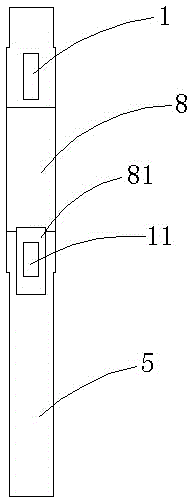

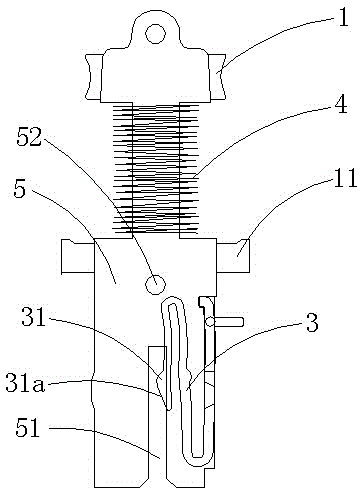

[0030] Such as Figure 1 to Figure 6 Shown is the structural representation of the present invention,

[0031] The reference signs are: iron core 1, suction head 11, circuit board 2, contact copper sheet 3, contact point 31, inclined surface 31a, coil 4, winding skeleton 5, card slot 51, assembly hole 52, Spring 6, iron hook 7, mounting hole 7a, suction end 71, hook-shaped end 72, spring installation part 73, electromagnet shell 8, buffer protection injection molded body 81, weaving rod 91, plastic hook 92, hook belt 93.

[0032] Such as Figure 1 to Figure 6 as shown,

[0033] The jacquard electromagnet assembly with double injection molding structure includes an iron core 1, which is used to connect the contact copper sheet 3 and the coil 4 of the circuit board 2, wherein the iron core 1 is injection molded with a winding skeleton 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com