Engine piston rod measuring tool

A technology for measuring tooling and piston connecting rods, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve problems such as poor versatility, high precision requirements, and difficult processing of measuring tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

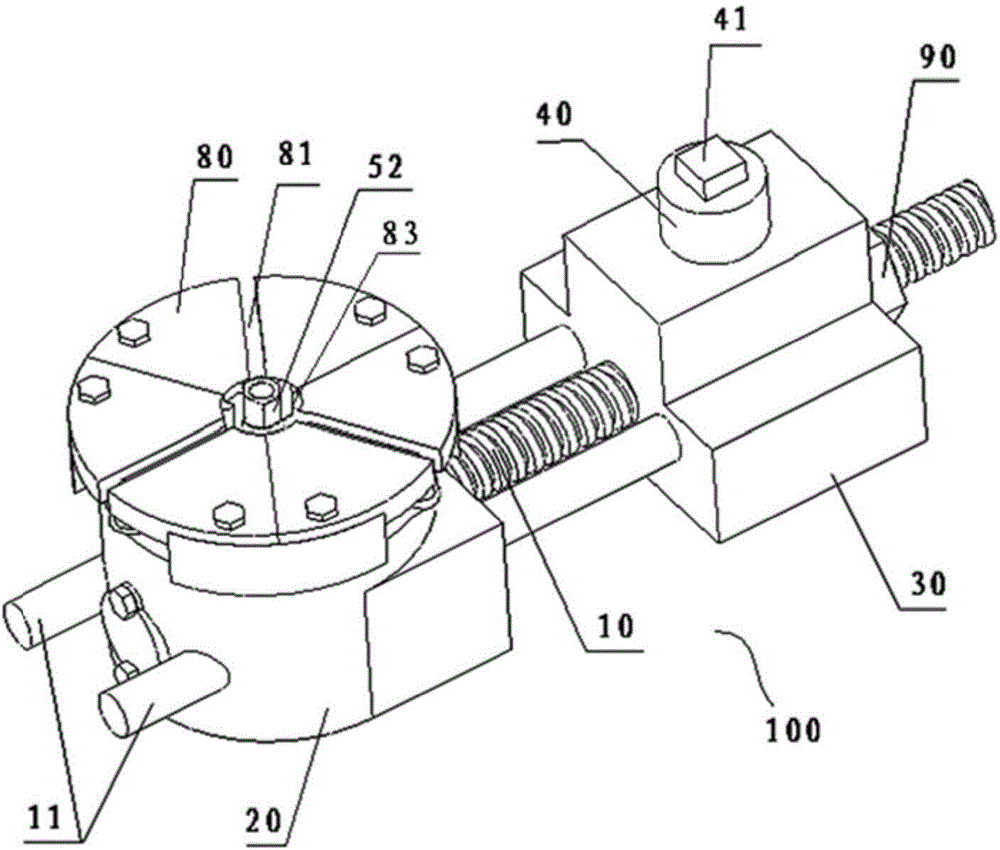

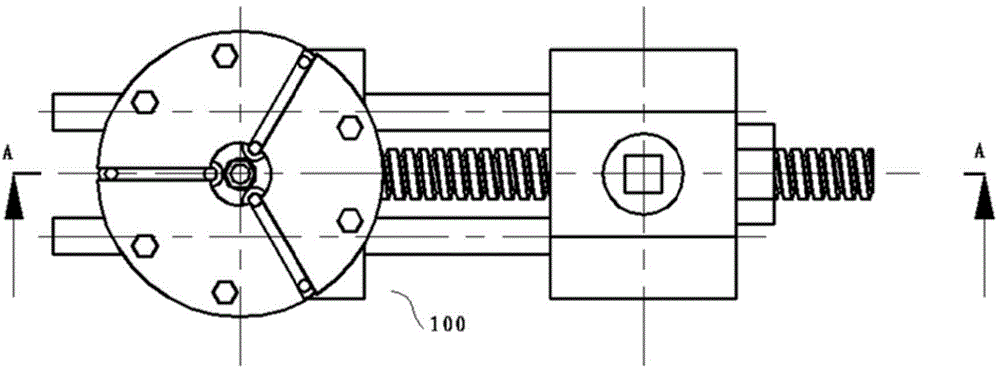

[0035] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

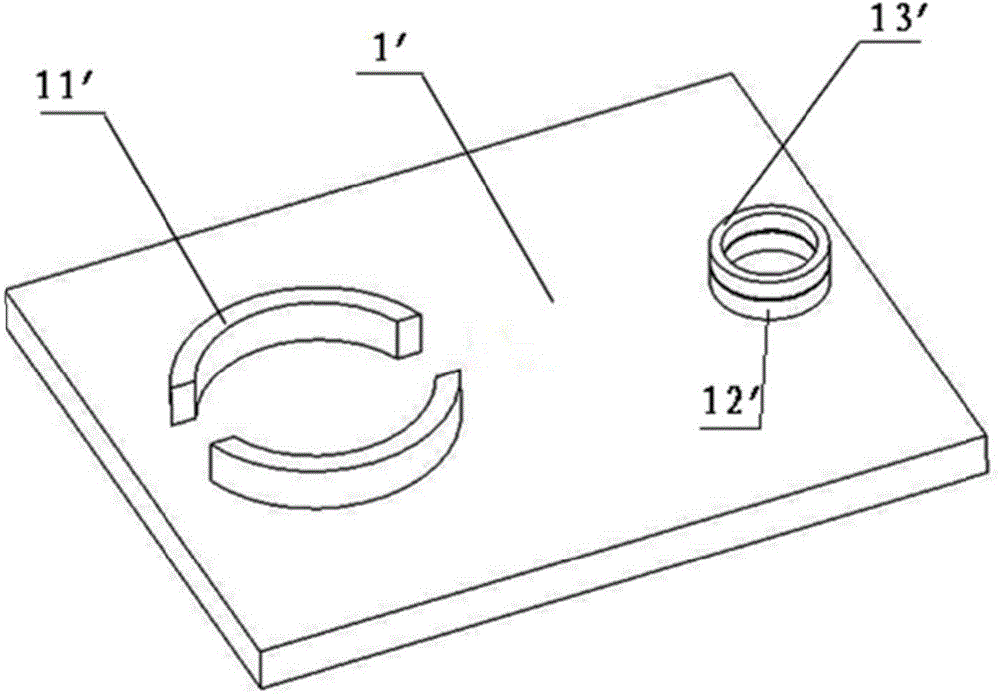

[0036] combine Figure 2-12 As shown, the present invention provides a measuring tool 100 for the piston connecting rod of an engine. In order to solve the defects in the prior art, the present invention adopts the following technical solution: it includes an adjusting mandrel 10 extending in the horizontal direction, one end of which is fixed Connected to the workbench 20, the other end is slidingly connected to the adjustment slider 30. The adjustment slider 30 is provided with an adjustment platform 40 for adjusting the height in the vertical direction. One end of 60 is hinged to the adjustment disc 50, and the other end is hinged to the guide rocker arm 70. The guide plate 80 fixed to the workbench 20 is provided with at least two slide groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com