A method and system for testing the minimum bending radius of a full-scale non-metallic pipe

A technology of bending radius and testing system, applied in the direction of applying stable tension/pressure to test material strength, measuring device, analyzing materials, etc., can solve problems such as inability to test and determine, and achieve simple and feasible test methods, simple and easy settings, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

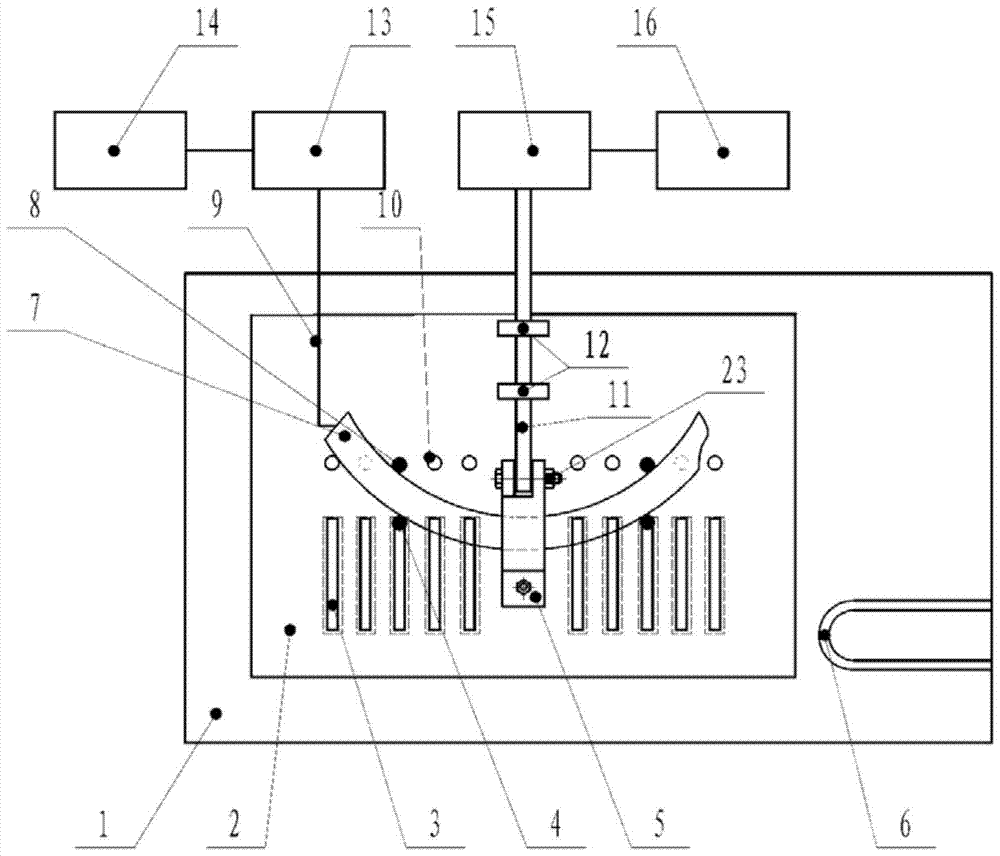

[0055] Example 1: Test the minimum storage bending radius of DN150 polyethylene pipe at room temperature

[0056] (1) Sample preparation: take a polyethylene pipe with a length of 1000mm as the test pipe sample;

[0057] (2) Pipe connection: connect the processed polyethylene pipe to the hydrostatic blasting tester;

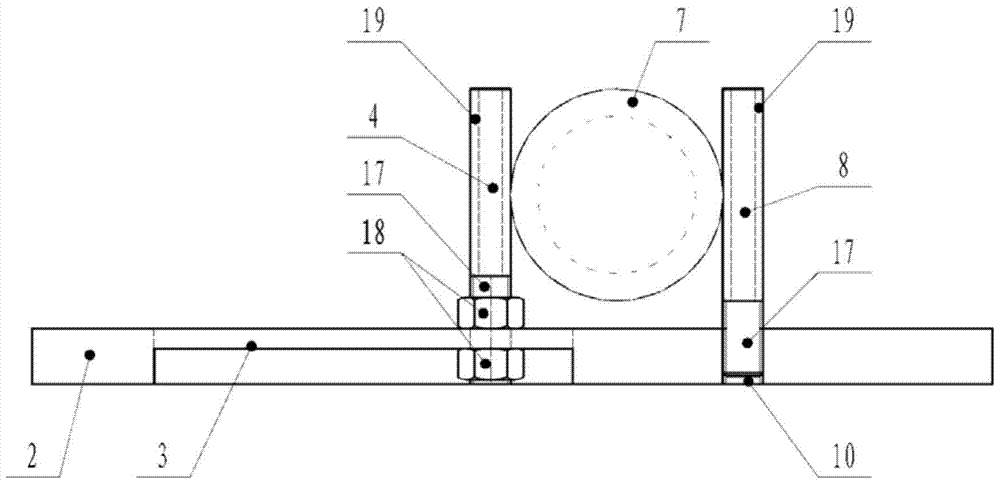

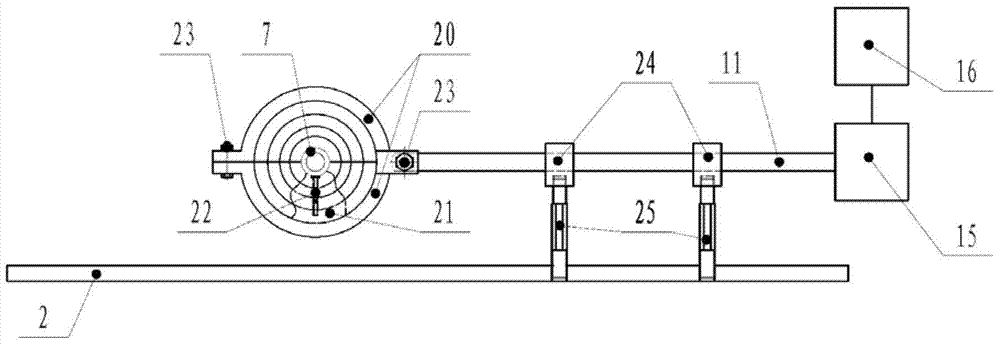

[0058] (3) Place the sample: first select the appropriate clamping block according to the outer diameter of the test tube sample, and clamp the middle of the test tube sample in the clamp; adjust the height of the two adjustable fixed piles to ensure that the transmission rod is The center of the test tube sample is on the same horizontal line; according to the length and outer diameter of the test tube sample, determine the position of the fixing bolt and the sliding bolt to complete the clamping and fixing of the two ends of the test tube sample.

[0059] (4) Setting of the bending system: Set the distance between the two fixing bolts to the chord length, combine with ...

Embodiment 2

[0063] Example 2: Test the minimum working bending radius of DN100 flexible composite pipe at 50°C

[0064] (1) Sample preparation: take a flexible composite tube with a length of 1200mm as the test tube sample;

[0065] (2) Pipe connection: connect the processed flexible composite pipe to the hydrostatic blasting tester;

[0066] (3) Place the sample: first select the appropriate clamping block according to the outer diameter of the test tube sample, and clamp the middle of the test tube sample in the clamp; adjust the height of the two adjustable fixed piles to ensure that the transmission rod is The center of the test tube sample is on the same horizontal line; according to the length and outer diameter of the test tube sample, determine the position of the fixing bolt and the sliding bolt to complete the clamping and fixing of the two ends of the test tube sample.

[0067] (4) Setting of the bending system: Set the distance between the two fixing bolts as the chord length, and cal...

Embodiment 3

[0071] Example 3: Verify the minimum storage bending radius of DN150 polyethylene pipe under room temperature conditions

[0072] (1) Sample preparation: take a polyethylene pipe with a length of 1000mm as the test pipe sample;

[0073] (2) Pipe connection: connect the processed polyethylene pipe to the hydrostatic blasting tester;

[0074] (3) Place the sample: first select the appropriate clamping block according to the outer diameter of the test tube sample, and clamp the middle of the test tube sample in the clamp; adjust the height of the two adjustable fixed piles to ensure that the transmission rod is The center of the test tube sample is on the same horizontal line; according to the length and outer diameter of the test tube sample, determine the position of the fixing bolt and the sliding bolt to complete the clamping and fixing of the two ends of the test tube sample.

[0075] (4) Bending system setting: Set the distance between the two fixing bolts to the chord length, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com