Main insulating anti-corona structure optimization calculating method used for high-voltage motor

A technology of anti-halo structure and high-voltage motor, which is applied in the direction of calculation, electrical digital data processing, special data processing application, etc. It can solve the problems of motor instability, efficiency reduction, and excessive consumption of artificial and material resources, so as to save manpower and material resources, The effect of improving design efficiency and avoiding repeated modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

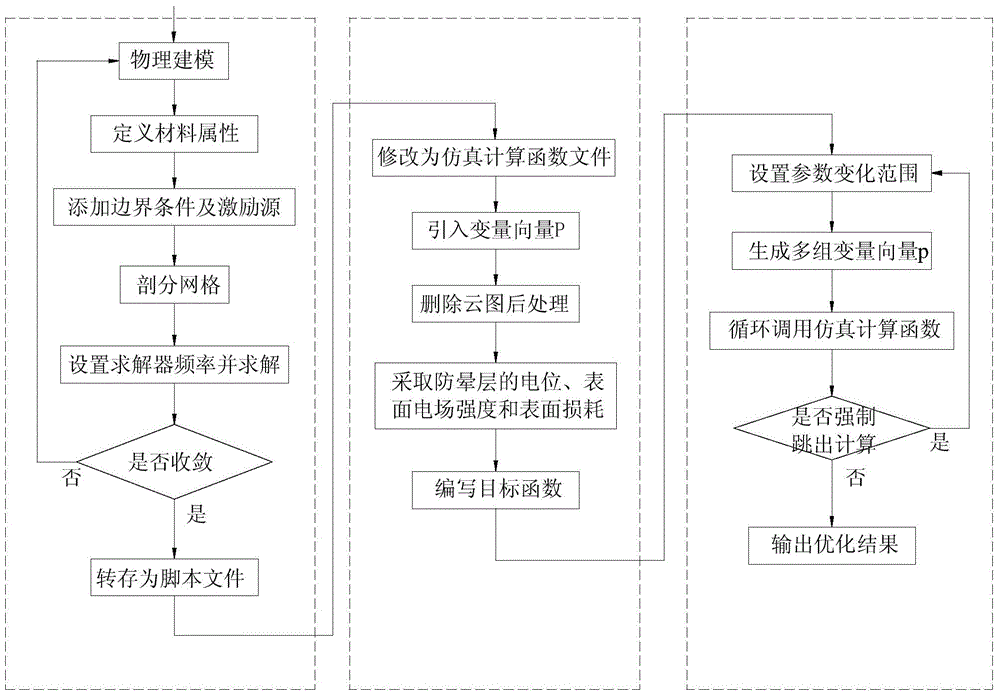

[0034] Such as figure 1 As shown, the steps of the calculation method for optimizing the anti-corona structure of the main insulation of the high-voltage motor in this embodiment include:

[0035]1) Use the finite element multi-physics field coupling simulation software to physically model the main insulation anti-corona structure of the high-voltage motor, define material properties, add boundary conditions and excitation sources, subdivide the grid, set the solver frequency and solve, and the solution is completed Then save the calculation process as a script file;

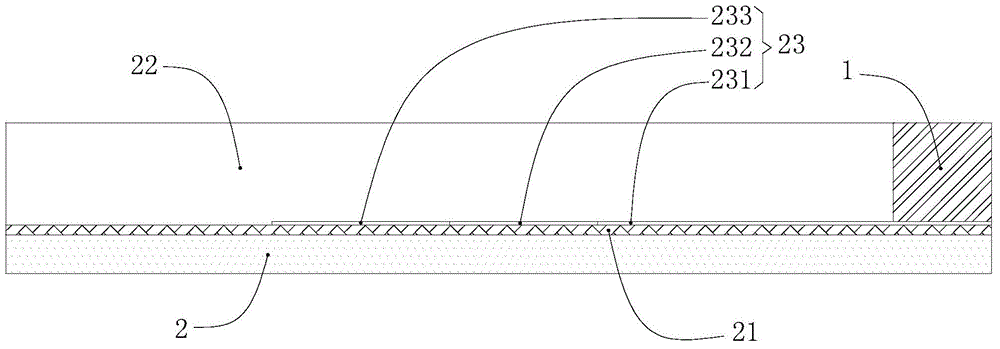

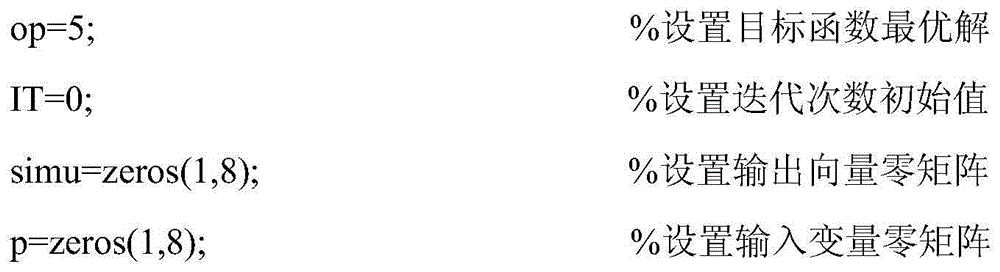

[0036] 2) Modify the script file into a simulation calculation function file, introduce the anti-halation structure parameters to be optimized into the variable vector p as the input variable of the simulation calculation function, delete the original cloud image post-processing statement in the script file and adopt the physical In the model, the potential of the end of the anti-corona layer relative to the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com