Optical detector based on BiCuSeO thermoelectric thin-film transverse thermoelectric effect

A lateral thermoelectric, bismuth copper selenide technology, applied in the direction of thermoelectric device node lead-out material, electric solid device, circuit, etc., can solve the problems of wide response band, high detection sensitivity, low detection sensitivity, etc., to achieve wide response band , the effect of high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

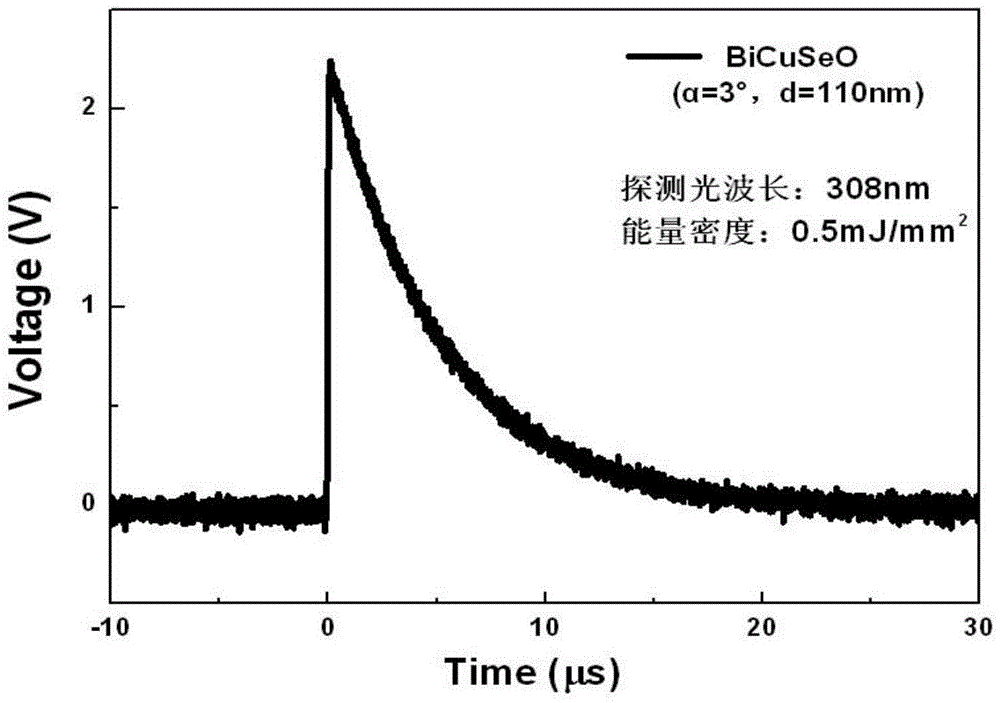

[0026] Example 1

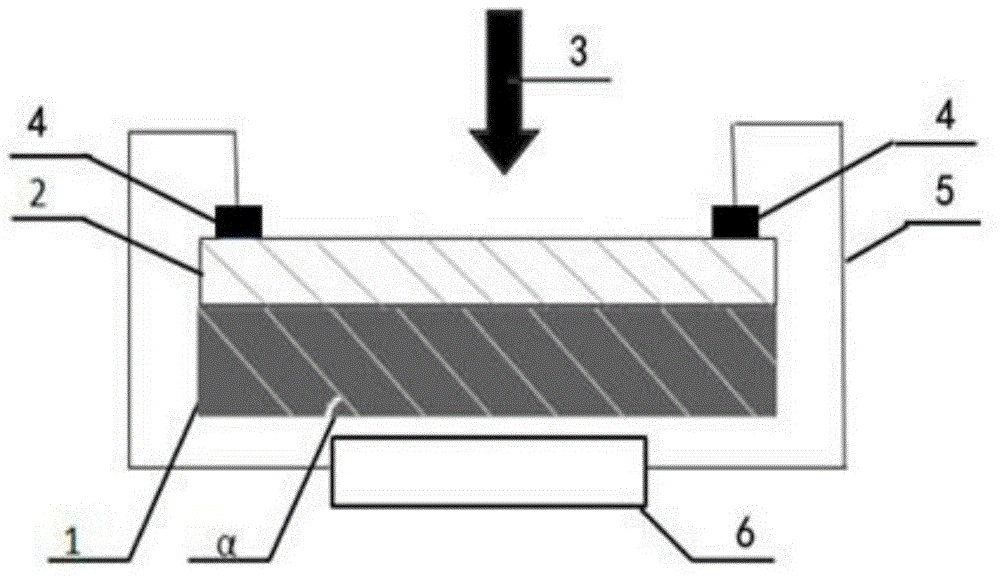

[0027] 1. The transverse thermoelectric element adopts LaAlO obliquely cut at 3° on the c axis 3 A layer of bismuth-copper-selenium-oxygen thin film with a thickness of 110nm grown obliquely along the c-axis was prepared on a single crystal substrate with a tilt angle of 3°.

[0028] The specific preparation process is as follows: Weigh Bi according to the atomic molar ratio of the chemical formula BiCuSeO 2 O 3 , Elemental Cu, Bi and Se are mixed to obtain a mixture material, the mixture material is ground in a ball mill for 30 hours, the ground material is pressed into a disc with a thickness of 3mm and a diameter of 25mm, and the above disc is vacuum sealed Technology The wafer is encapsulated in a quartz tube and then sintered by a high-temperature solid-phase reaction method to obtain the required bismuth copper selenium oxide polycrystalline ceramic target. Put the obtained bismuth-copper-selenium-oxygen polycrystalline ceramic target into the PLD cavity, a...

Example Embodiment

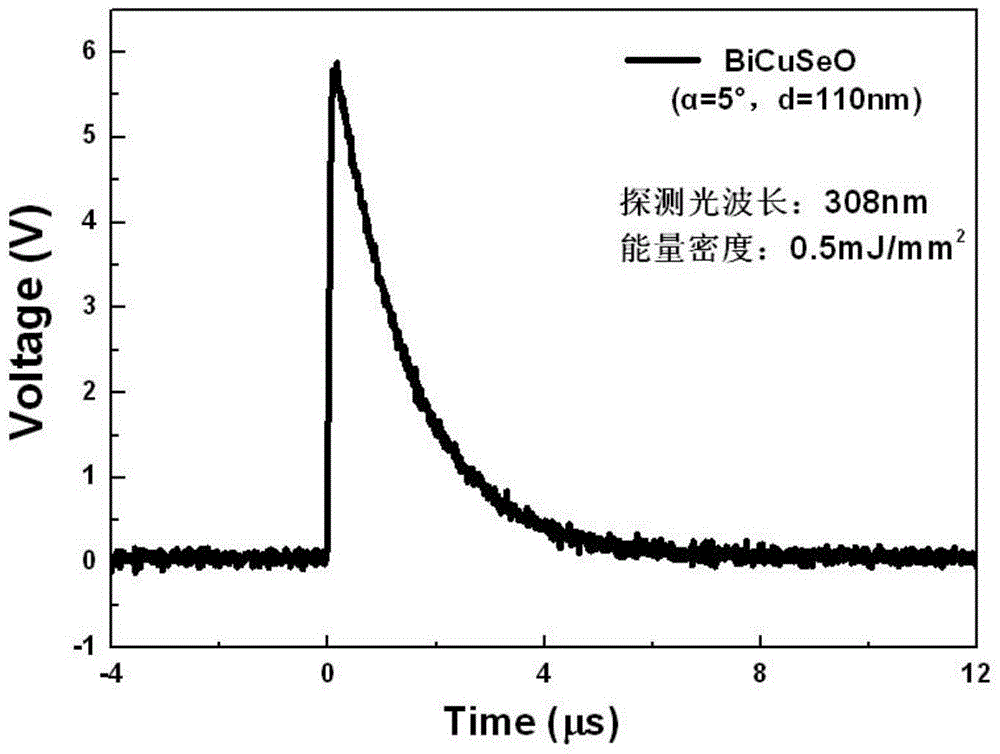

[0034] Example 2

[0035] 1. The transverse thermoelectric element adopts LaAlO which is obliquely cut at 5° on the c axis 3 A layer of bismuth-copper-selenium-oxygen thin film with a thickness of 110nm and grown obliquely along the c-axis was prepared on a single crystal substrate with a tilt angle of 5°.

[0036] The specific preparation process is as follows: Weigh Bi according to the atomic molar ratio of the chemical formula BiCuSeO 2 O 3 , Elemental Cu, Bi and Se are mixed to obtain a mixture material, the mixture material is ground in a ball mill for 30 hours, the ground material is pressed into a disc with a thickness of 3mm and a diameter of 25mm, and the above disc is vacuum sealed Technology The wafer is encapsulated in a quartz tube and then sintered by a high-temperature solid-phase reaction method to obtain the required bismuth copper selenium oxide polycrystalline ceramic target. Put the obtained bismuth-copper-selenium-oxygen polycrystalline ceramic target into the ...

Example Embodiment

[0042] Example 3

[0043] 1. The transverse thermoelectric element adopts LaAlO which is obliquely cut 10° on the c axis 3 A layer of bismuth-copper-selenium-oxygen thin film with a thickness of 110nm and grown obliquely along the c-axis was prepared on a single crystal substrate with a tilt angle of 10°.

[0044] The specific preparation process is as follows: Weigh Bi according to the atomic molar ratio of the chemical formula BiCuSeO 2 O 3 , Elemental Cu, Bi and Se are mixed to obtain a mixture material, the mixture material is ground in a ball mill for 30 hours, the ground material is pressed into a disc with a thickness of 3mm and a diameter of 25mm, and the above disc is vacuum sealed Technology The wafer is encapsulated in a quartz tube and then sintered by a high-temperature solid-phase reaction method to obtain the required bismuth copper selenium oxide polycrystalline ceramic target. Put the obtained bismuth-copper-selenium-oxygen polycrystalline ceramic target into the P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com