Winding arrangement and wiring structure for single-phase asynchronous motor

A single-phase asynchronous, wiring structure technology, applied in the direction of asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of difficult phase-to-phase insulation treatment, poor effect, difficult automated mass production, etc., to achieve easy automated mass production, The effect of automated production convenience, wide application and promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

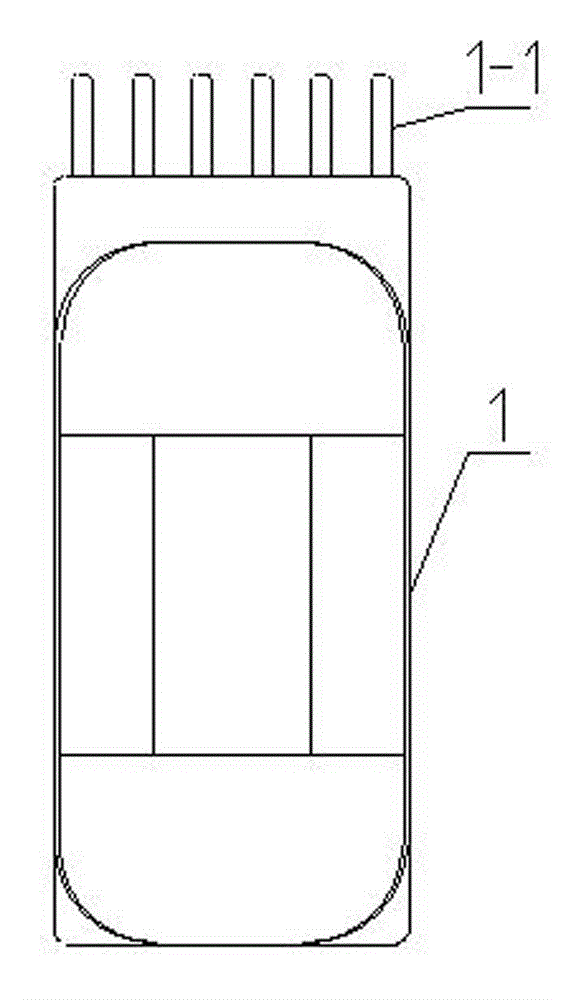

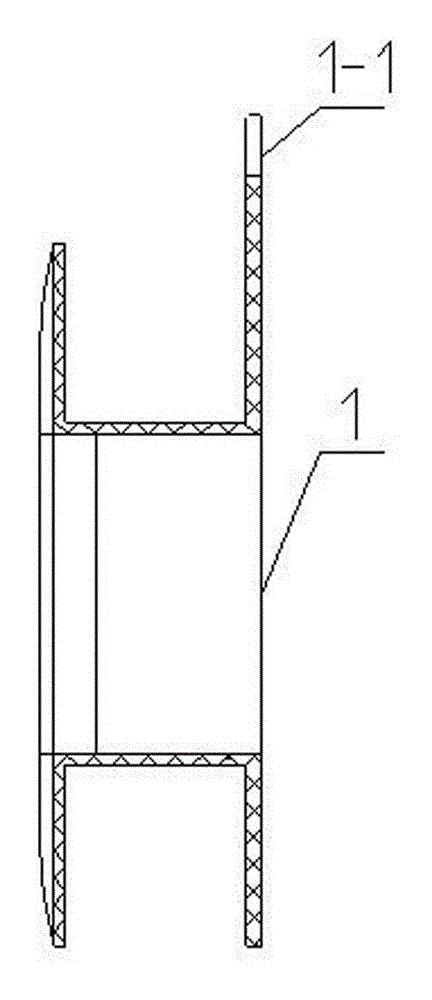

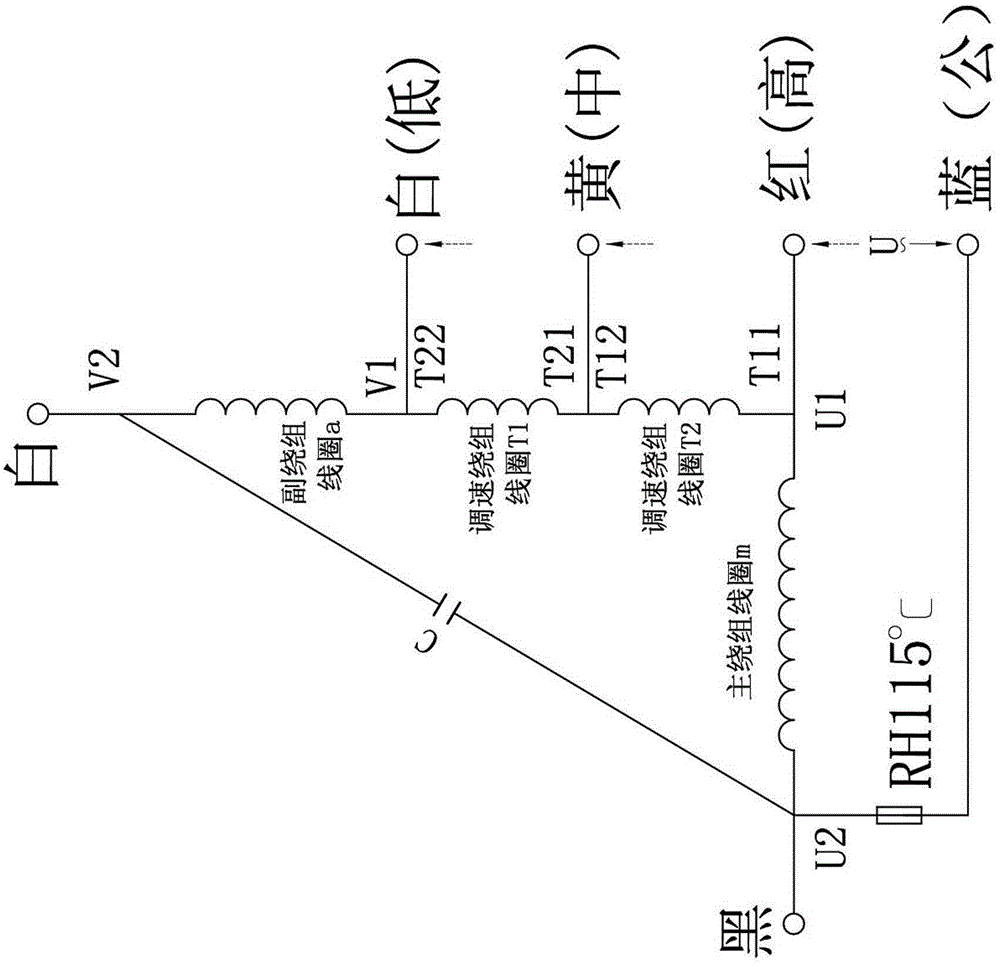

[0022] This embodiment includes a printed circuit board and an electromagnetic coil connected to the printed circuit board. The electromagnetic coil of this embodiment includes a main winding coil m, an auxiliary winding coil a and a speed regulating winding coil T 1 ~T 2 . Main winding coil m, secondary winding coil a and speed regulating winding coil T 1 ~T 2 The composition and structure are the same, and the main winding coil m is taken as an example to illustrate its structure. The main winding coil m is composed of a bobbin 1 and a coil wound on the bobbin 1, and the bobbin 1 is provided with a terminal 1-1 for connecting a printed circuit board, see figure 1 and figure 2 . About the main winding coil m, the secondary winding coil a and the speed regulating winding coil T 1 ~T 2 wiring and wiring structure, see image 3 . image 3 The shown single-phase as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com