A stepped groove circuit board and its processing method

A processing method and step groove technology, applied in printed circuit, printed circuit manufacturing, printed circuit parts, etc., to achieve the effect of not being easily polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

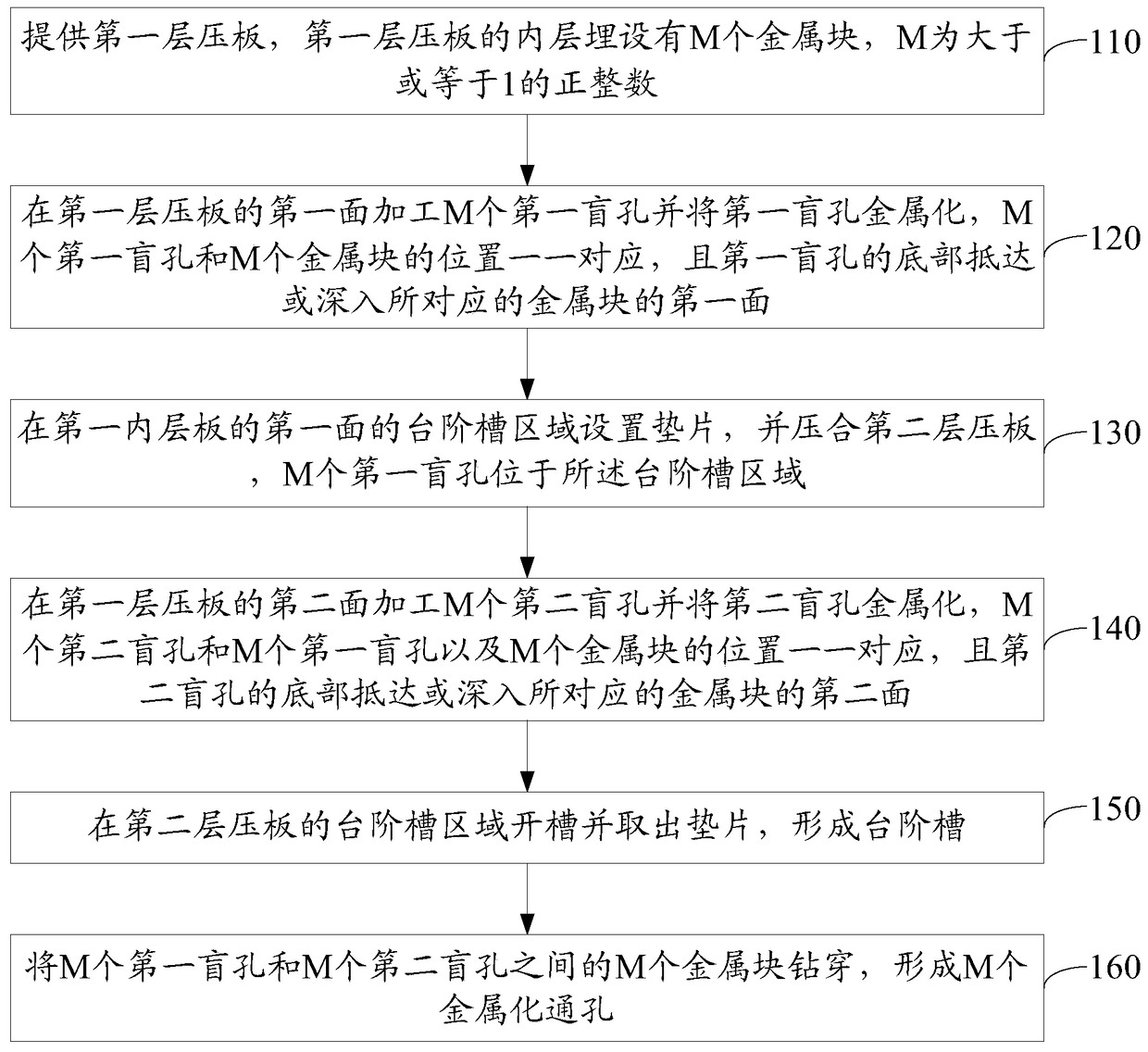

[0038] Please refer to figure 1 , an embodiment of the present invention provides a method for processing a stepped groove circuit board, which may include:

[0039] 110. Provide a first laminate, where M metal blocks are embedded in the inner layer of the first laminate, where M is a positive integer greater than or equal to 1.

[0040] Assume that a multilayer circuit board of (P+Q) layer needs to be made in the end, wherein P and Q are both positive integers greater than or equal to 1; and step grooves need to be processed on the multilayer circuit board, assuming Located on the (P+1)th floor to (P+Q)th floor.

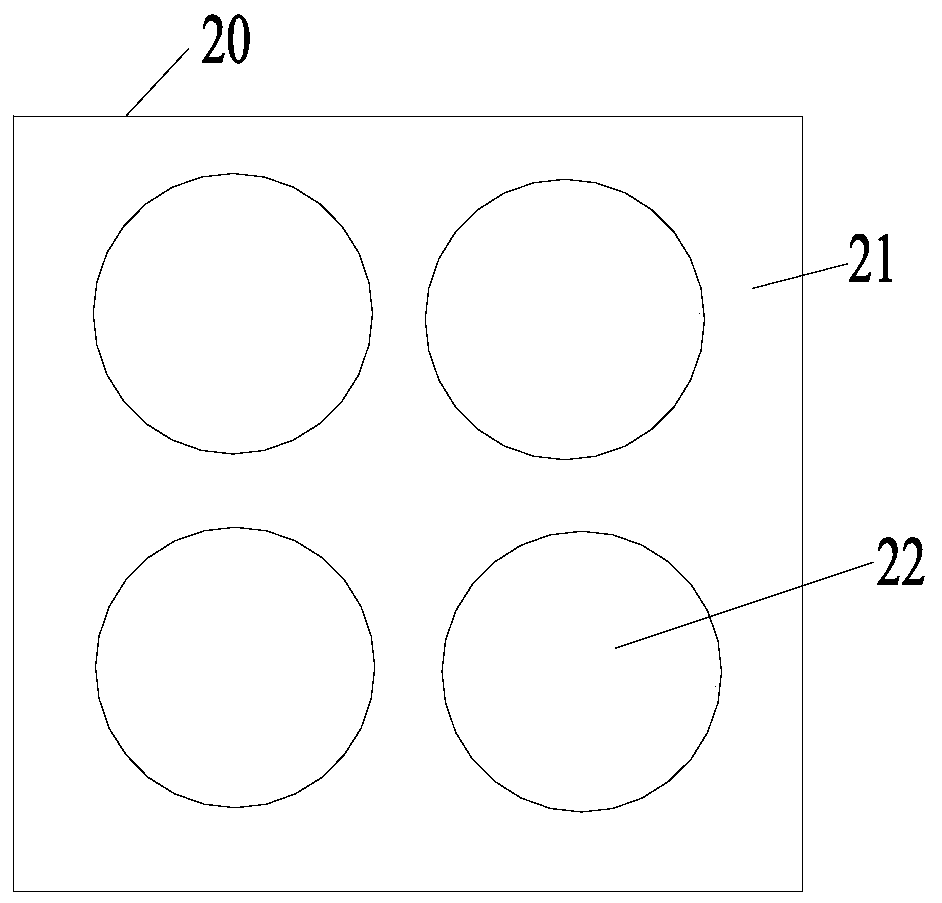

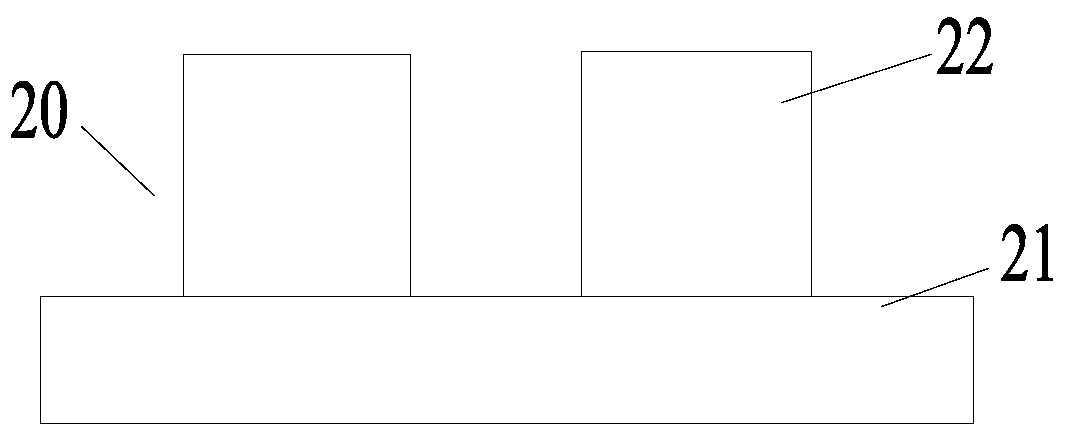

[0041] In this step, the first laminate is prefabricated, and the first laminate includes the first layer to the Pth layer. Assuming that the bottom of the stepped groove of the stepped groove circuit board is designed with M metallized through holes, the M metalized through holes need to be located in the stepped groove area of the first laminate and run throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com