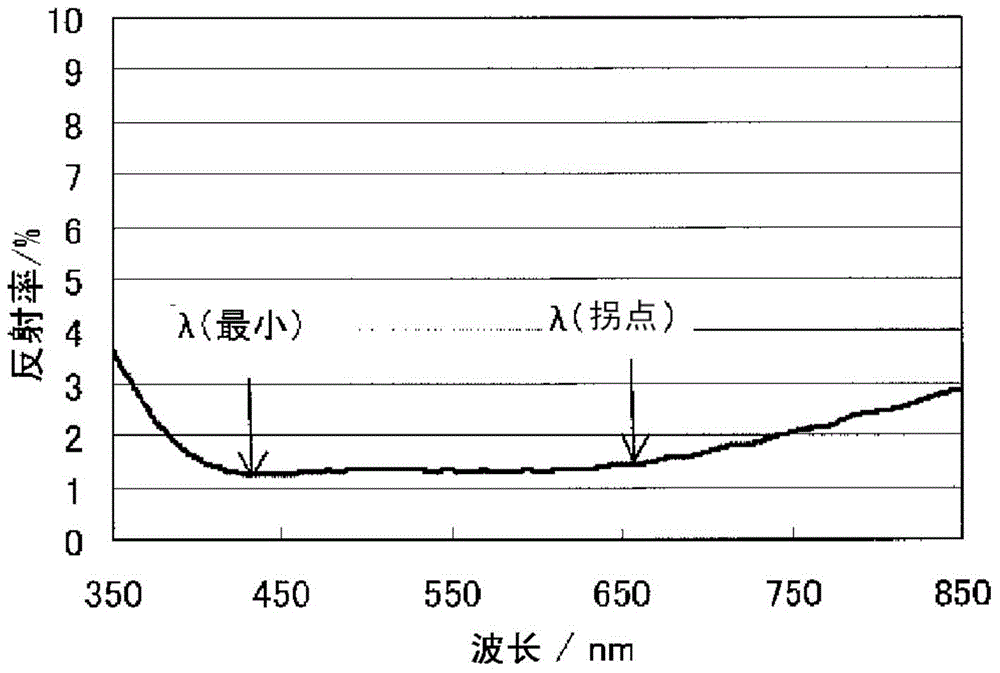

Fingerprint-resistant anti-reflection film

An anti-reflection film, anti-fingerprint technology, used in optics, instruments, layered products, etc., can solve the problem of not completely preventing the adhesion of sebum and dirt, and achieve full anti-reflection, improved erasability, and small appearance changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

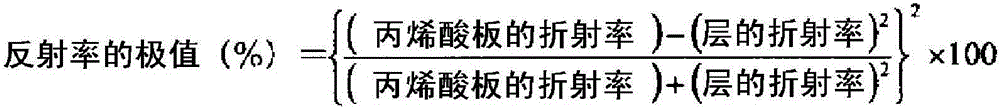

Method used

Image

Examples

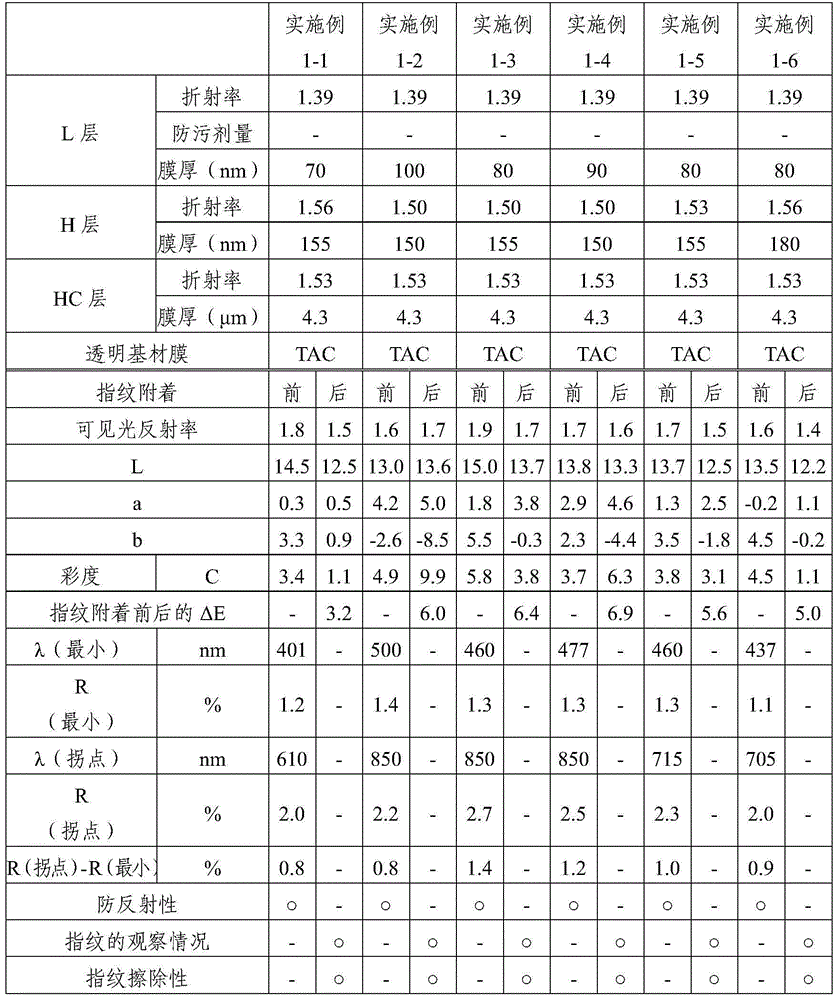

Embodiment 1-1

[0141] On a transparent substrate film formed of a triacetylcellulose (TAC) film having a thickness of 80 μm, a roll coater was used to apply a composition for forming a hard coat layer (manufactured by TOYO INK ( Co., Ltd., Lioduras LAS1303NL), dried at 80° C. for 2 minutes. Then, in a nitrogen atmosphere, irradiate ultraviolet rays with a 120W high-pressure mercury lamp (manufactured by Nippon Battery Co., Ltd.) (cumulative light intensity: 300mJ / cm 2 ) to cure the composition for forming a hard coat layer to form a hard coat layer. The refractive index of this hard coat layer was 1.53.

[0142] Next, the composition H-1 for forming a high refractive index layer was coated on the hard coat layer so that the thickness at the time of drying was 155 nm, and then an ultraviolet irradiation device (manufactured by EYE GRAPHICS Co., Ltd., 120 W high pressure) was used under a nitrogen atmosphere. Mercury lamp) was irradiated with 300 mJ of ultraviolet rays to cure the compositio...

Embodiment 1-2

[0145] Except using the composition H-2 for forming a high refractive index layer, setting the film thickness of the high refractive index layer to 150 nm, and setting the film thickness of the low refractive index layer to 100 nm, it was produced in the same manner as in Example 1-1. Films of Examples 1-2.

Embodiment 1-3

[0147] The film of Example 1-3 was produced in the same manner as in Example 1-2 except that the film thickness of the high refractive index layer was 155 nm and the film thickness of the low refractive index layer was 80 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com