Control method of chemical reaction vessel full-automatic ice adding device

A technology of chemical reaction kettle and control method, which is applied in chemical instruments and methods, electrical program control, chemical/physical process, etc. It can solve the problems of inaccurate ice shape, loss of economic benefits, and occupation of large human resources. Achieve the effects of perfecting automated intelligent production, reducing production input costs, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

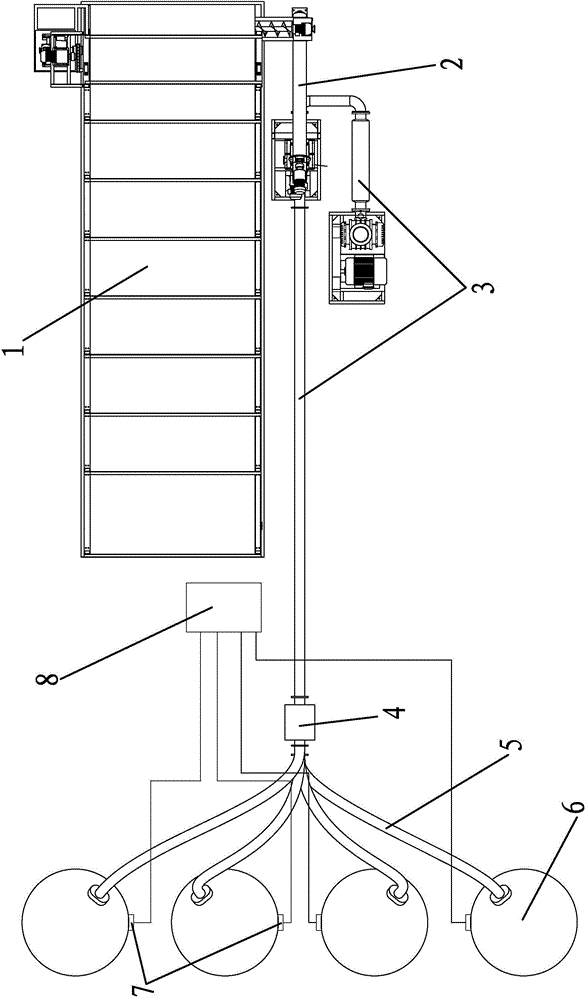

[0025] Such as figure 1 As shown, the automatic ice adding device for the chemical reaction kettle includes a crawler type ice storage 1 and several reaction tanks 6 . The ice outlet of crawler-type ice storage 1 is connected to the screw metering ice feeder 2, the screw metering ice feeder 2 is connected to the pneumatic ice feeding device 3, the pneumatic ice feeding device 3 is connected to the pipeline conversion ice feeder 4, and the pipeline conversion ice delivery The device 4 is connected with a plurality of conveying pipes 5, and the conveying pipes 5 and the reaction tank 6 are connected in one-to-one correspondence. The reaction tank 6 is provided with a temperature sensor 7, and the temperature sensor 7 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com