Air-pressing tool fixture and application thereof

A tooling and air pressure technology, applied in the field of tooling and fixtures, can solve the problems of contradicting the starting point of tooling design, increasing factors to be considered, and different pipe diameters, etc., and achieve the effect of shortening production cycle, convenient transportation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 A pneumatic fixture

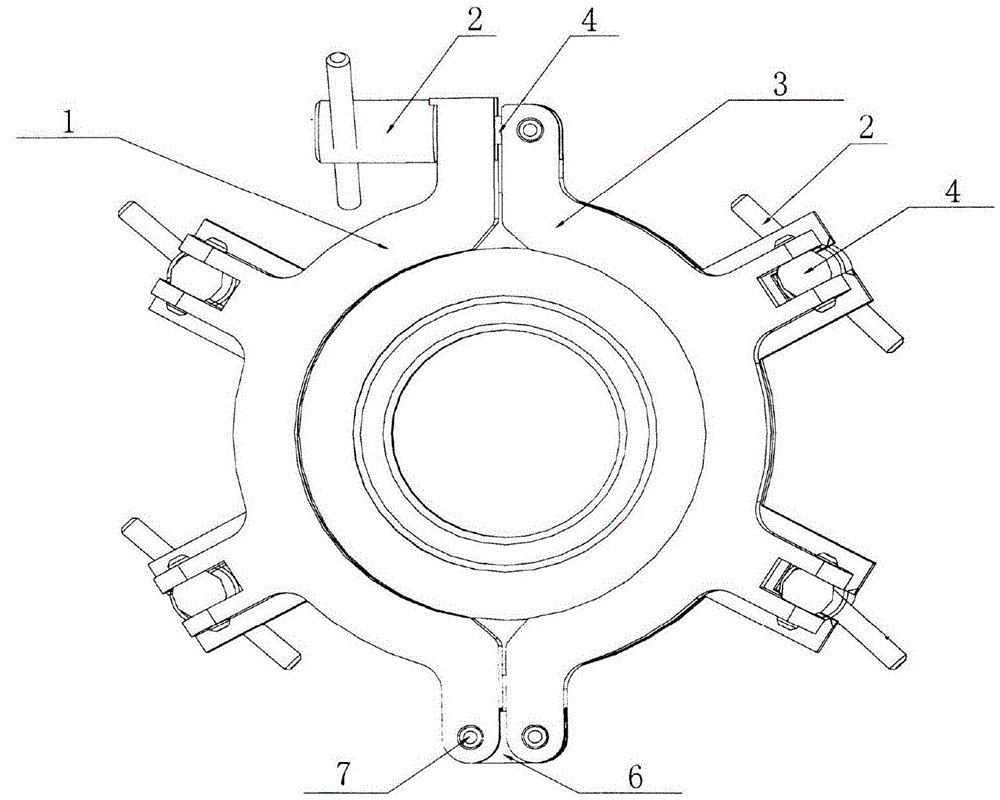

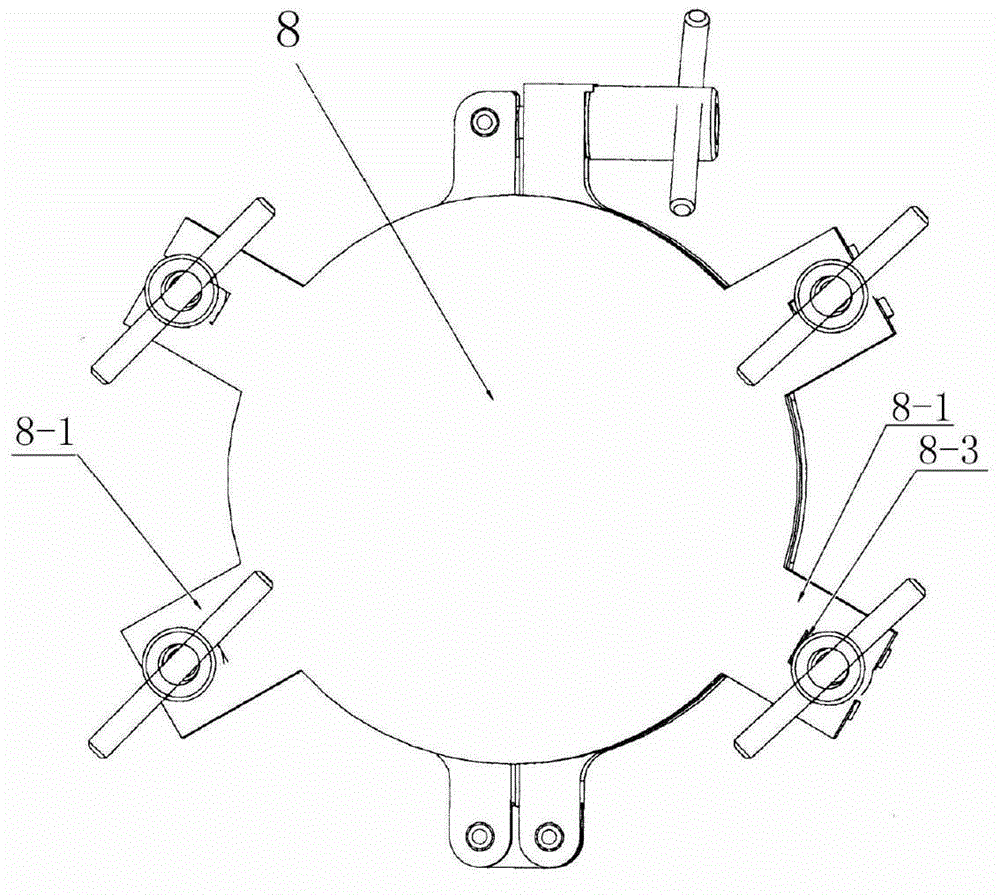

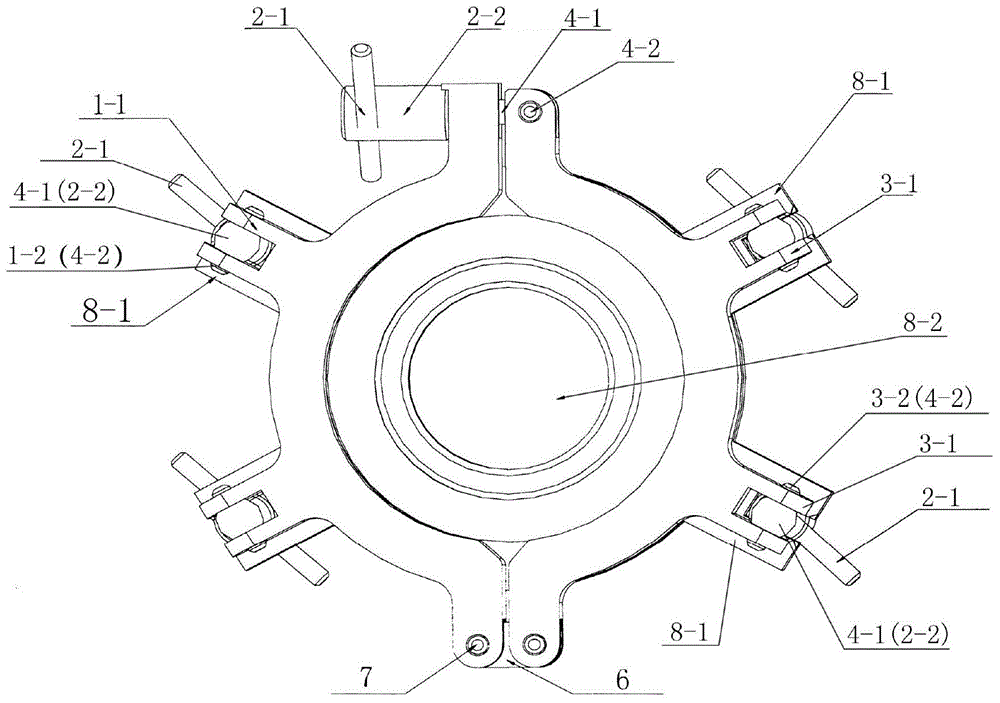

[0022] Such as Figure 1-Figure 3 As shown, a pneumatic tooling fixture: consists of a left supporting plate (1), a handle nut (2), a right supporting plate (3), a handle bolt (4), a connecting plate (6), a connecting bolt (7) and a blocking cover (8) Composition.

[0023] The left supporting plate (1) is provided with several connection parts I (1-1), the connection parts I (1-1) are U-shaped structures, and pin holes I (1-2) are provided at both ends.

[0024] The right supporting plate (3) is provided with several connection parts II (3-1), the connection part II (3-1) is a U-shaped structure, and pin holes II (3-2) are provided at both ends.

[0025] The handle nut (2) consists of a handle portion (2-1) and a nut portion (2-2).

[0026] One end of the handle bolt (4) is provided with a threaded portion (4-1), and the other end both sides are provided with a cylindrical pin (4-2).

[0027] A connecting part III (8-1) correspondi...

Embodiment 2

[0034] Embodiment 2 The application of pneumatic fixtures in the strength and airtightness inspection of conduit parts.

[0035] The method is as follows: Fit the end of the catheter-like parts to be tested with the ring-shaped part positioning part (8-2) of the blocking cover (8), pass the handle nuts at the ends of the left supporting plate (1) and the right supporting plate (3) Cooperate with the handle bolts to tighten the left supporting plate (1) and the right supporting plate (3) to ensure the radial compression of the catheter parts to be tested; through the connecting part I (1-1) of the left supporting plate (1) and The fit between the handle nut and the handle bolt between the connecting part III (8-1) of the blocking cover, and the connecting part II (3-1) of the right support plate (3) and the connecting part III (8-1) of the blocking cover The cooperation between the handle nut and the handle bolt ensures the axial compression of the catheter parts to be tested. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com