Tin tank bottom brick

A tin bath bottom brick and additive technology, which is applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of easy peeling and floating of the reaction layer of the tin bath bottom brick, and achieve the effect of improving chemical stability and mechanical strength.

Inactive Publication Date: 2015-09-16

ZHEJIANG RUITAI REFRACTORY TECH

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The technical problem solved by the present invention provides a tin bath bottom brick, which solves the problem that the reaction layer of the tin bath bottom brick is easy to peel off and float up

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

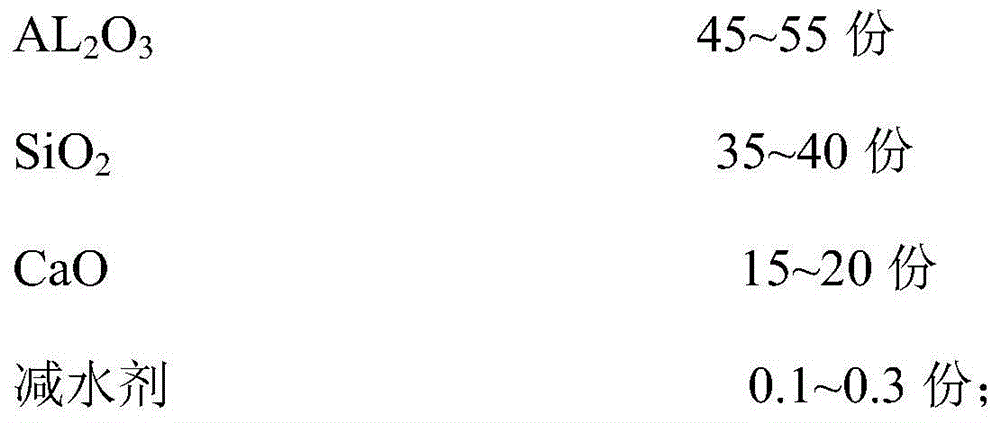

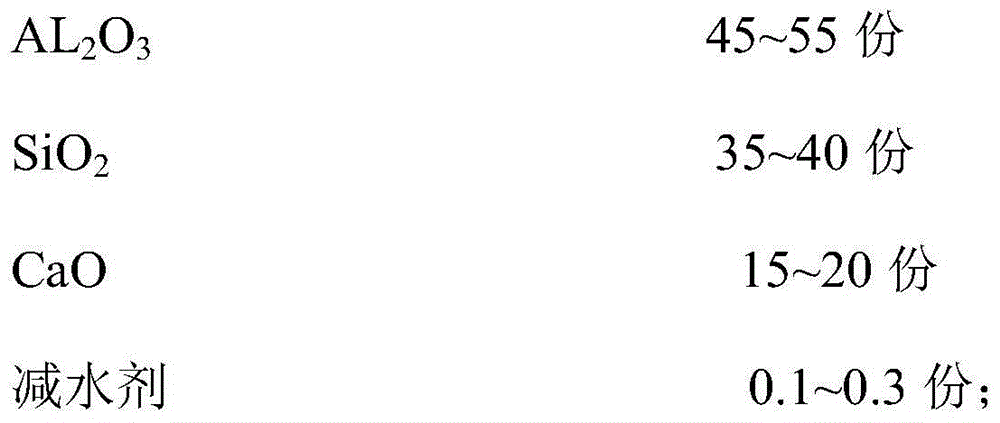

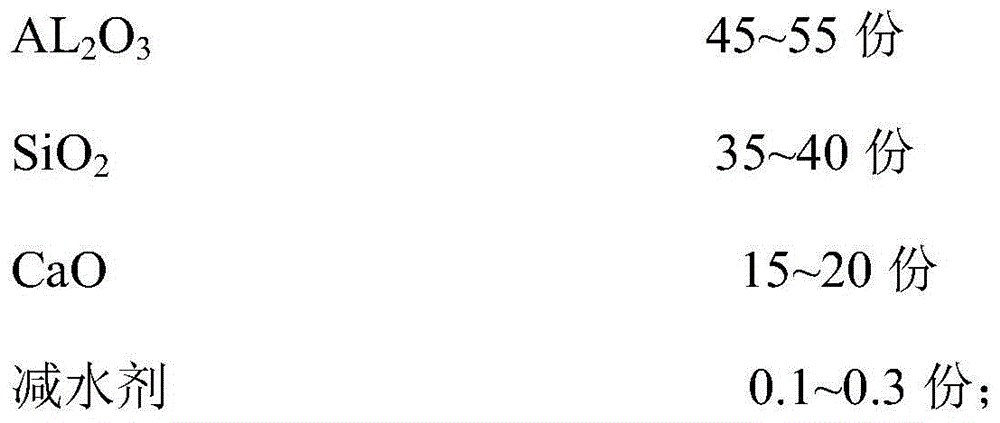

[0012] A kind of tin bath bottom brick of the present invention comprises main material and additive, and described main material comprises following component and the weight part of each component is:

[0013]

[0014] The additive comprises the following components and the parts by weight of each component are:

[0015] R 2 O 1~1.5 parts

[0016] Fe 2 o 3 1.4~1.6 parts

[0017] ZrO 2 1.2 to 1.5 parts.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a tin tank bottom brick. The problems of easy spalling and upward floating of reaction layers of tin tank bottom bricks are solved in the invention. The tin tank bottom brick comprises a main material and an additive, wherein the main material comprises, by weight, 45-55 parts of Al2O3, 35-40 parts of SiO2, 15-20 parts of CaO, and 0.1-0.3 parts of a water reducer; and the additive comprises, by weight, 1-1.5 parts of R2O, 1.4-1.6 parts of Fe2O3 and 1.2-1.5 parts of ZrO2.

Description

technical field [0001] The invention relates to a tin bath bottom brick. technical background [0002] The bottom brick of the tin bath is a special refractory material used to build the inner lining of the tin bath. Since the bottom brick will form silicate glass during high temperature sintering, the Na 2 O penetrates into the pores of the bottom brick and reacts to form nepheline minerals, which causes the volume expansion of the tin bath bottom brick by about 20%, resulting in the peeling and floating of the reaction layer. Contents of the invention [0003] The technical problem solved by the invention provides a tin bath bottom brick, which solves the problem that the reaction layer of the tin bath bottom brick is easy to peel off and float up. [0004] A tin bath bottom brick, comprising main ingredients and additives, the main ingredients include the following components and the parts by weight of each component are: [0005] [0006] The additive comprises th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B5/43C03B18/16C04B35/66

Inventor 范圣良

Owner ZHEJIANG RUITAI REFRACTORY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com