Polyolefin anion exchange membrane based on block structure and preparation method thereof

An anion-exchange membrane and polyolefin technology, applied in fuel cells, electrochemical generators, electrical components, etc., can solve the problems of uncontrollable distribution of ion-conducting groups, limit ion conductivity, and affect service life, etc., to improve chemical Effects of Stability and Mechanical Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

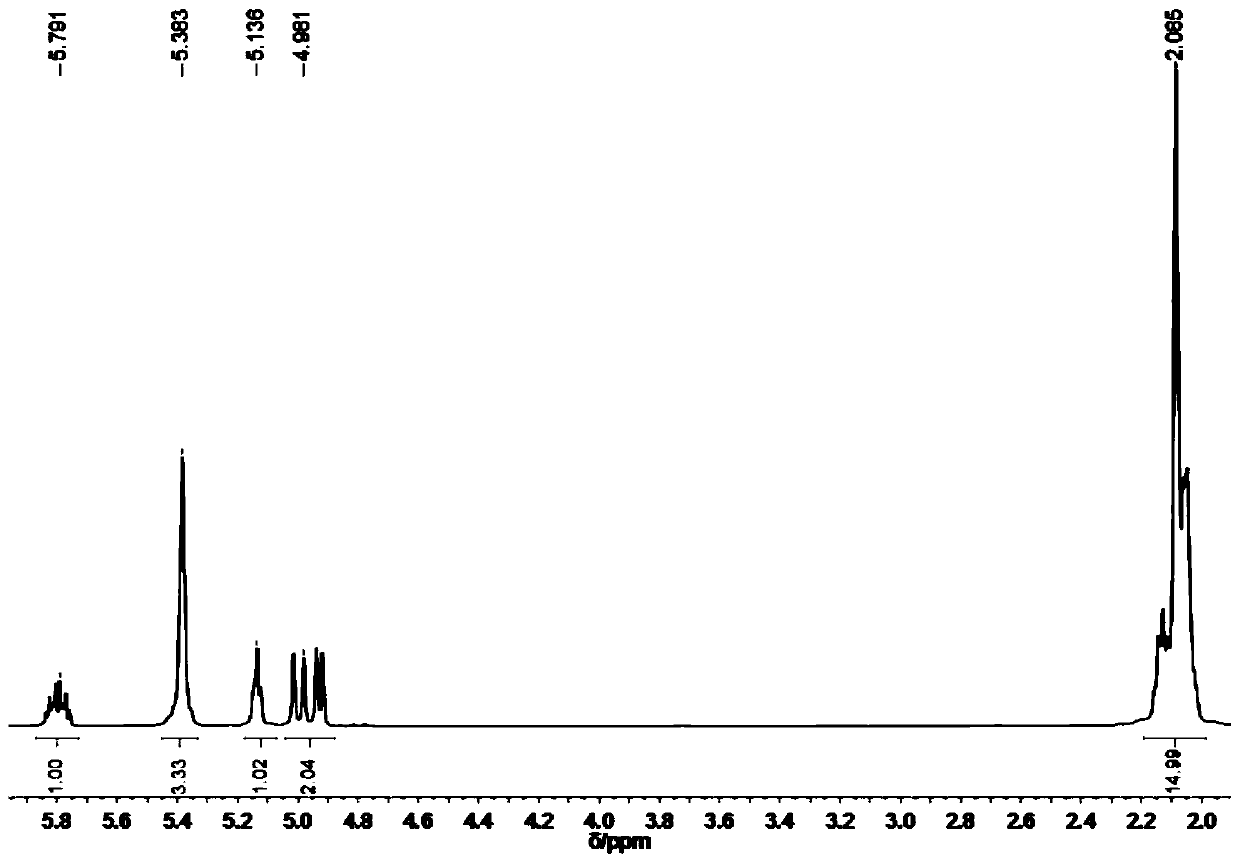

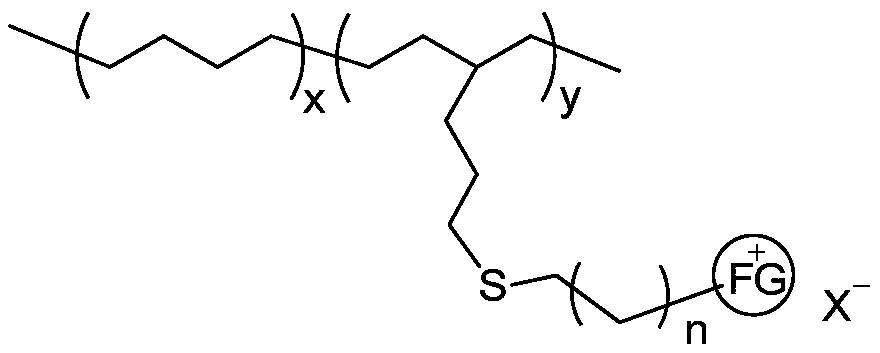

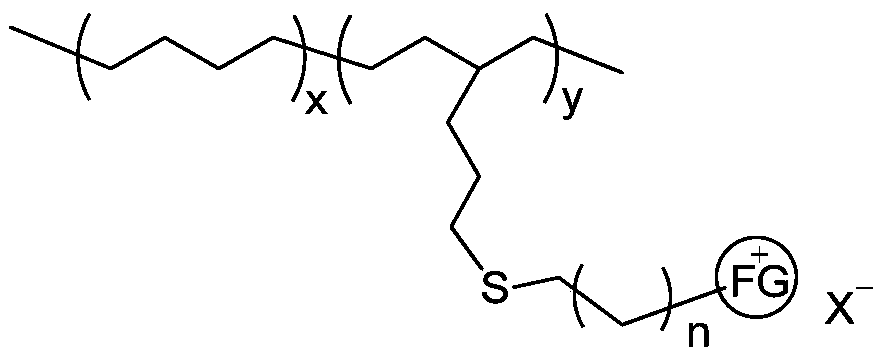

[0042](1) Preparation of block structure polyolefin main chain: under inert gas protection, add initiator and 3-methylene-1,6-heptadiene (0.64g 6mmol) in the reaction flask, add 4mL toluene, stir 5min, then add butadiene toluene solution (4mL12mmol) and continue to stir for 10min, methanol solution terminates the reaction, the reaction solution is settled with ethanol, and a solid polymer is precipitated, filtered, washed, and dried; 3-methylene-1,6 - Heptadiene and butadiene copolymer membrane material backbone.

[0043] (2) Preparation of anion exchange membrane based on block structure polyolefin main chain: In a flask, dissolve 3-methylene-1,6-heptadiene and butadiene copolymer (0.1g 0.6mmol) in 5mL In THF, then add nitrogen-containing mercaptopyrrolidine quaternary ammonium salt (0.25g 1.7mmol), under nitrogen condition, airtight reaction system, replace gas three times, under the ultraviolet irradiation of wavelength 365nm, react 20min, stop irradiation 10min, then conti...

Embodiment 2

[0048] (1) Preparation of block structure polyolefin main chain: under inert gas protection, add initiator and 3-methylene-1,6-heptadiene (1.3g 12mmol) in the reaction flask, add 5mL toluene, stir 10min, then add butadiene toluene solution (4mL12mmol) and continue to stir for 20min, ethanol solution terminates the reaction, the reaction solution is settled with acetone, and a solid polymer is precipitated, filtered, washed, and dried; 3-methylene-1,6 - Heptadiene and butadiene copolymer membrane material backbone.

[0049] (2) Preparation of anion exchange membrane based on block structure polyolefin main chain: In a flask, dissolve 3-methylene-1,6-heptadiene and butadiene copolymer (0.1g 0.6mmol) in 5mL In chloroform, add nitrogen-containing mercaptomorpholine quaternary ammonium salt (0.36g 2.5mmol) then, under nitrogen condition, airtight reaction system, displacement gas is three times, under the ultraviolet irradiation of wavelength 365nm, react 30min, stop irradiation 20...

Embodiment 3

[0054] (1) Preparation of block structure polyolefin main chain: under inert gas protection, add initiator and 3-methylene-1,6-heptadiene (2.6g 24mmol) in reaction flask, add 5mL toluene, stir 20min, then add butadiene toluene solution (4mL12mmol) and continue to stir for 30min, propanol solution terminates the reaction, the reaction solution is settled with ether, and a solid polymer is separated out, filtered, washed, and dried; 3-methylene-1, 6-heptadiene and butadiene copolymer film material backbone.

[0055] (2) Preparation of anion exchange membrane based on block structure polyolefin main chain: In a flask, dissolve 3-methylene-1,6-heptadiene and butadiene copolymer (0.1g 0.6mmol) in 5mL In dichloromethane, then add nitrogen-containing mercaptopiperidine quaternary ammonium salt (0.43g 3mmol), under nitrogen condition, airtight reaction system, replace gas three times, under the ultraviolet irradiation of wavelength 365nm, react 40min, stop irradiation 30min, then cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com