Molybdenum alloy dry cleaning equipment with squirrel-cage motor and flange piston dampers

A motor flange and dry cleaning equipment technology, applied in the field of washing machines, can solve the problems of easy cross-infection of bacteria on clothes, longer motor shaft seal, lack of effective anti-shock measures, etc., to achieve good shock absorption effect, sensitive steering, and rigid structure super effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

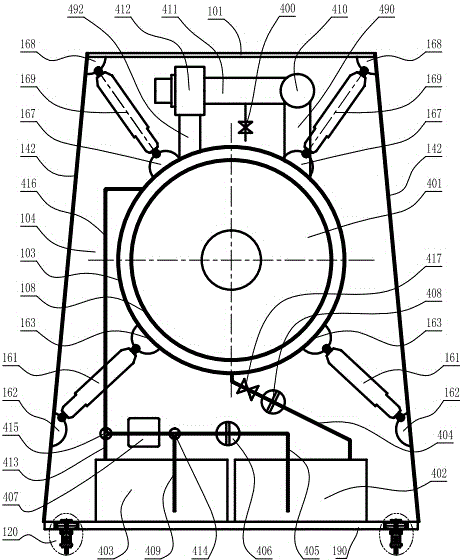

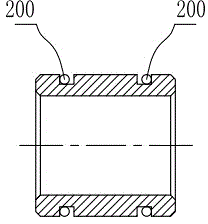

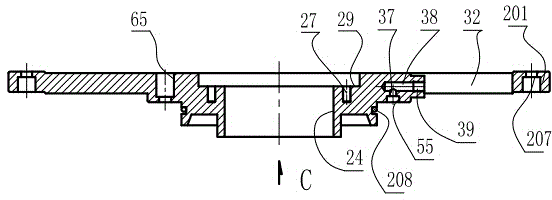

[0039] figure 1 , figure 2 and Figure 6 Middle: squirrel-cage motor flange piston shock-absorbing molybdenum alloy dry-cleaning equipment, including a casing 101 and a washing tub 401, and also includes a heat pump drying system, a solvent recovery system, an inner shock-absorbing assembly, an outer shock-absorbing wheel set 120, and a mouse Cage-type water-cooled motor assembly 110; the heat pump drying system includes a gas delivery device 412, a condenser 411, an evaporator 410, and a solvent recovery pipe valve 400, and the air inlet 492 and the air outlet 490 of the heat pump drying system are connected to The washing drum 401 is connected; the solvent recovery system includes a dirty liquid tank 402 and a clean liquid tank 403; the dirty liquid tank 402 is communicated with the washing drum 401 through a first pipeline 404; the dirty liquid t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com