Automatic-rotating rapid dismounting and mounting type spiral drill rod

An automatic rotating and helical drill pipe technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of low connection efficiency, increase the risk of workers' operation, etc., achieve convenient processing, improve performance and work efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

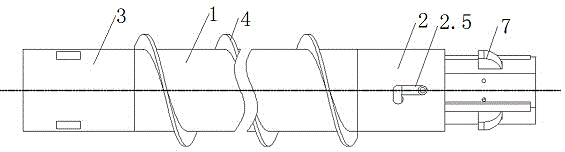

[0036] figure 1 The structure of the drill rod of the present invention is shown. A self-rotating and quick-detachable auger rod, comprising an intermediate rod 1, a male joint 2, and a female joint 3, the outer side of the intermediate rod 1 is provided with a helical blade 4, one end of the intermediate rod 1 is welded to the female joint 3, and the other end is welded to the female joint 3. The male joint 2 is welded; the male joint 2 and the female joint 3 are connected to the middle rod 1 through a friction welding process, and the spiral blade 4 is welded on the surface of the middle rod 1 with a pre-tightening force.

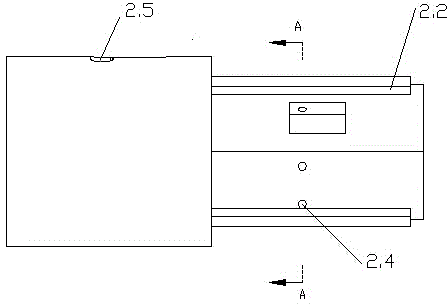

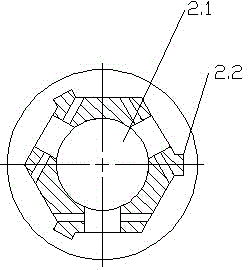

[0037] Figure 2~5 The structure of the male connector is shown. The male joint 2 is a cylinder with a blind hole 2.1 inside, the axis of the blind hole coincides with the overall central axis of the male joint, and the hole is a circular hole; the male joint is divided into three sections, the first section is a hexagonal prism structure, and the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com