Variable bent joint

A bendable and variable technology, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of low reuse rate and high cost of salvage tools, and achieve high salvage success rate, wide application range and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

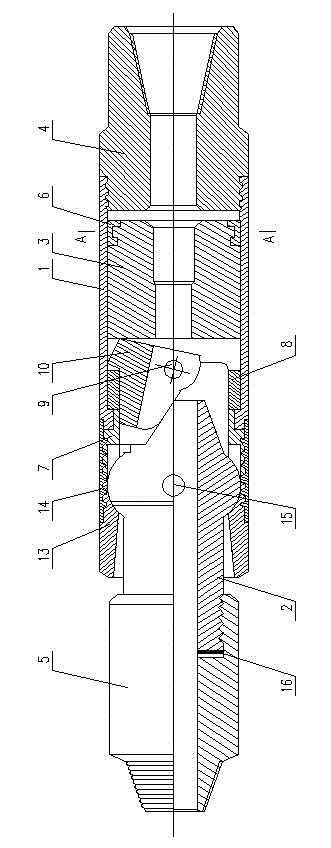

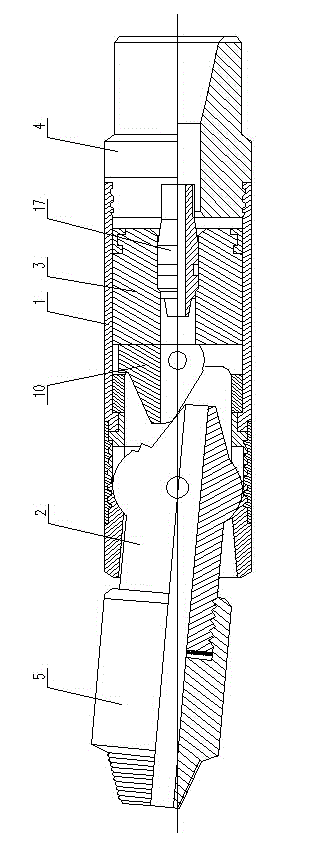

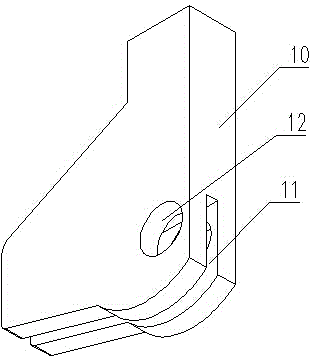

[0017] The bendable joint includes an outer cylinder 1 , an orientation joint 2 , a piston 3 , an upper joint 4 and a lower joint 5 . One end of the outer cylinder 1 is threaded with an upper joint 4 ; a piston 3 is installed in the outer cylinder 1 on one side of the upper joint 4 through a piston ring 6 . The piston ring 6 is a three-lobe ring, and the piston ring 6 is sleeved on the piston 3 . The other end of the outer cylinder 1 is screwed with an upper ball seat 7 , and a cam 10 is installed in the outer cylinder 1 between the upper ball seat 7 and the piston 3 by a cam seat 8 and a cam pin 9 . The cam 10 can rotate around the cam pin 9 to a certain extent. The cam 10 is flat and convex. The bottom of the cam 10 is provided with an assembly groove 11 , and the assembly groove 11 is provided with a cam pin hole 12 .

[0018] One side of the upper ball seat 7 is provided with a lower ball seat 13, and the upper ball seat 7 and the lower ball seat 13 are threadedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com