An anti-rotation plate structure with anti-rotation and anti-vibration functions

A technology of anti-rotation plate and rotary seal, which is applied to the structure of anti-rotation plate for flow diversion and vibration suppression. It has the field of anti-rotation and anti-rotation plate structure, and can solve the problem that the dynamic characteristics of the rotary seal rotor cannot be fundamentally improved and the effect is limited. , rotor vibration instability and other problems, to achieve the effect of increasing negative pre-rotation speed, improving stability and increasing effective damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

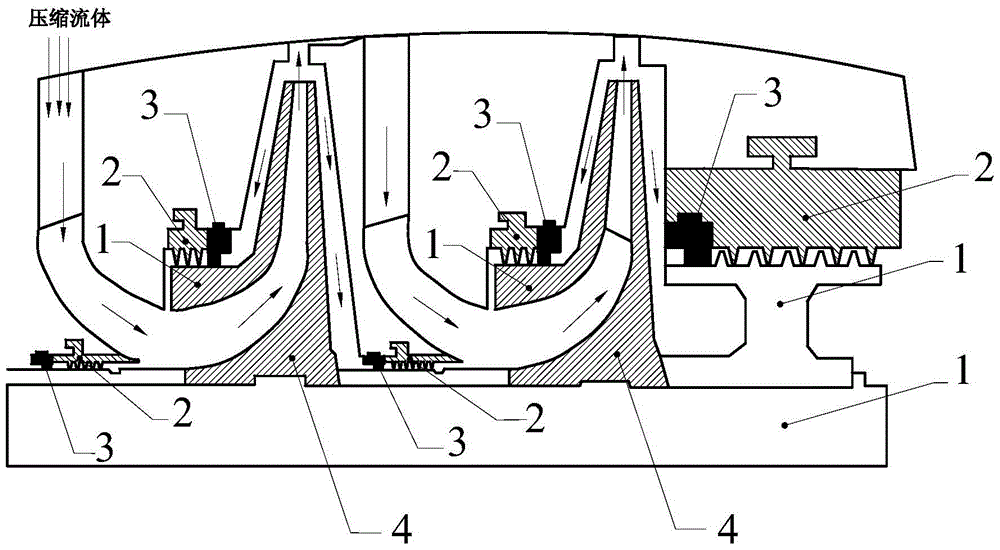

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

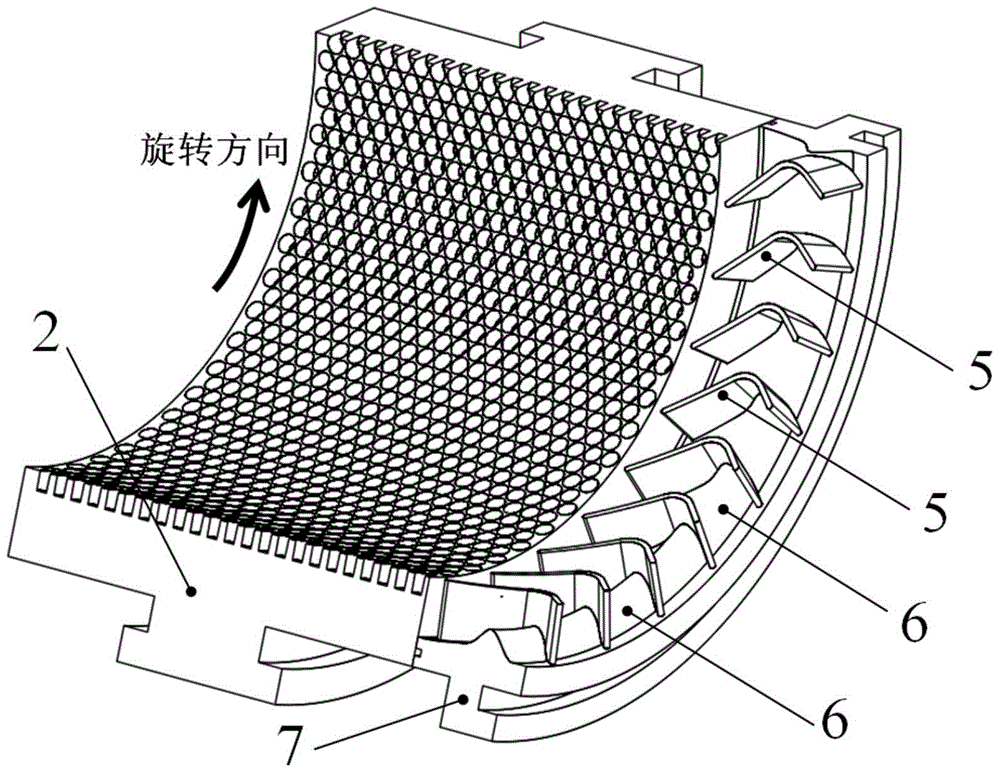

[0027] Concrete structure of the present invention sees appendix Figure 2-7 : The anti-rotation plate structure with anti-rotation and anti-vibration effect of the present invention is characterized in that a stator ring 7 is arranged upstream of the inlet of the rotary seal 2, and the radius of the inner surface of the stator ring 7 decreases gradually or first decreases along the axial direction Then increase; the inner surface of the stator ring 7, the deflector 5, and the outer surface of the rotating part 1 form an axially contracted or zoomed variable-section annular fluid channel to accelerate the expansion of the working fluid when flowing through the channel.

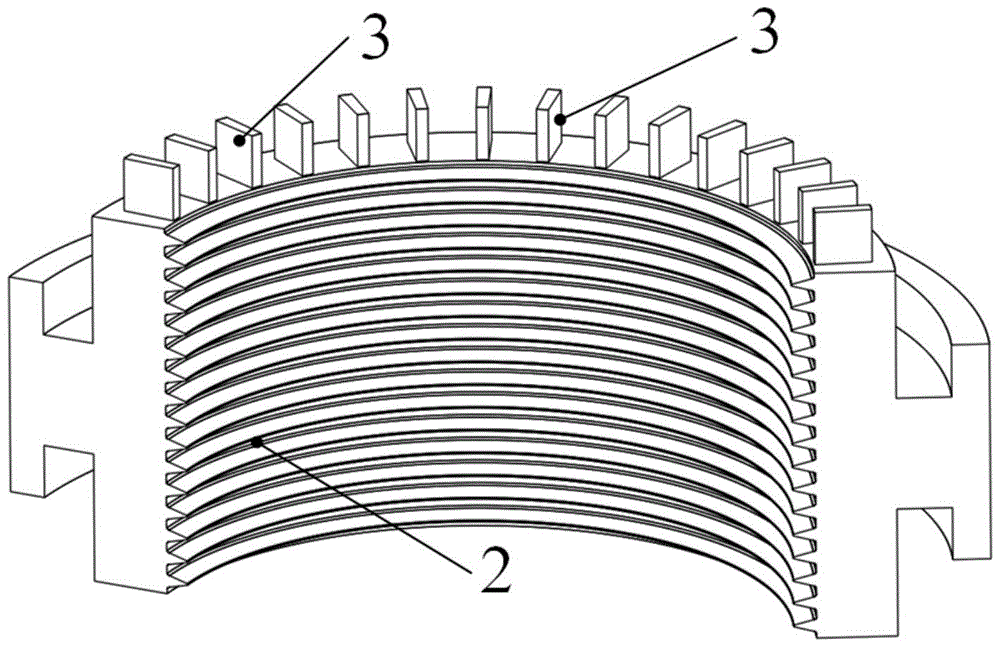

[0028] The sealing form of the rotary seal 2 is a labyrinth seal, a honeycomb seal, a hole-type seal or a bag-type damping seal. The axial profile of the stator ring inner surface 6 of the stator ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com