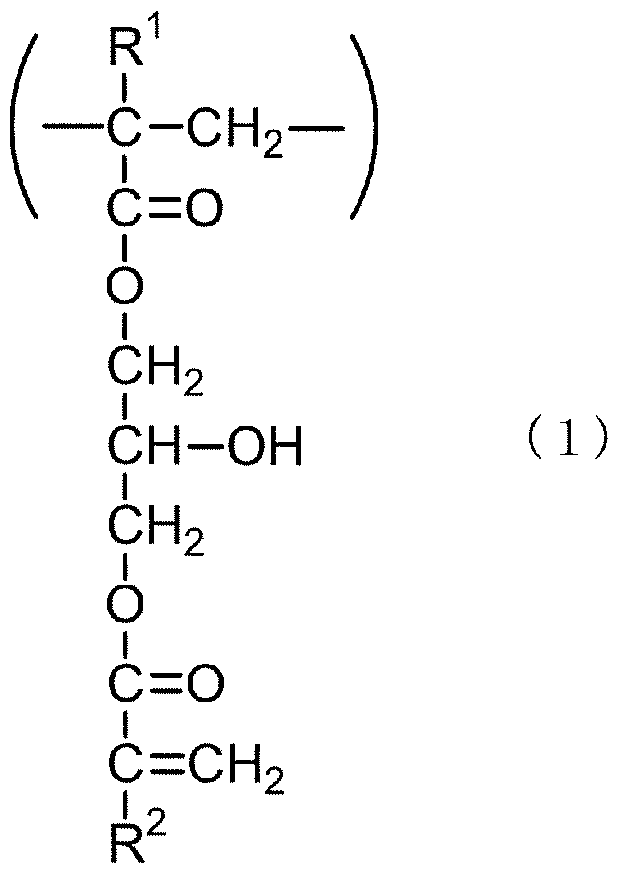

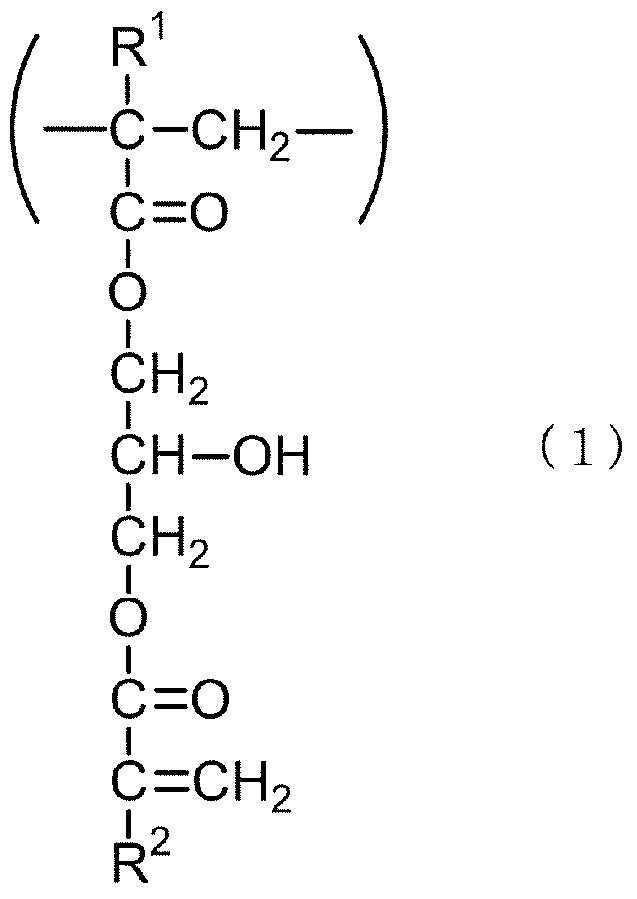

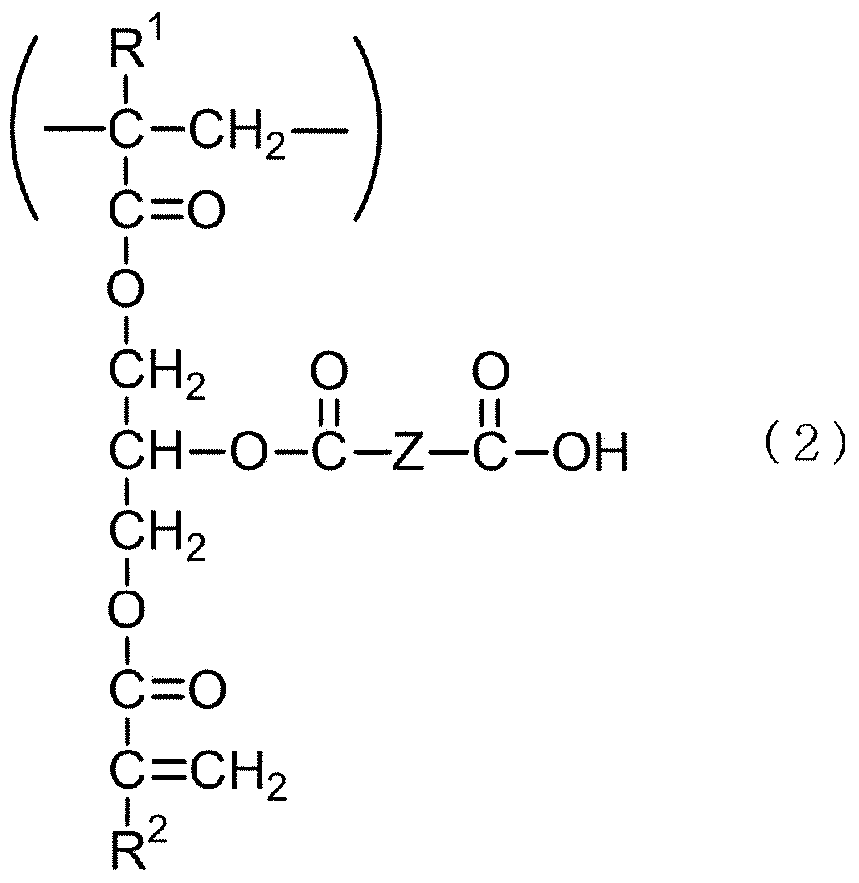

White photosensitive resin composition, cured product using the same, and touch panel containing the cured product as a component

A technology of photosensitive resin and composition, applied in the direction of photosensitive materials, optics, and optomechanical equipment used in optomechanical equipment, can solve the problems of insufficient light resistance, reduced light reflectivity, coloring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0086] Add MAA51.65g (0.60mol), MMA 38.44g (0.38mol), CHMA 36.33g (0.22mol), AIBN 5.91g and DMDG 368g in the 1000ml four-neck flask that nitrogen inlet tube and reflux cooler are attached, at 80 To 85 ° C under nitrogen flow, stirring for 8 hrs to polymerize. Further, 39.23g (0.28mol) of GMA, 1.44g of TPP, and 0.055g of DTBC were added to the flask, and stirred at 80 to 85°C for 16hr to obtain a (meth)acrylate resin (A)-1 containing a polymerizable unsaturated group . The obtained resin solution had a solid content concentration of 32% by mass, an acid value (in terms of solid content) of 110 mgKOH / g, and a weight average molecular weight (Mw) of 18,080 by GPC analysis.

[0087] (Preparation of White Photosensitive Photosensitive Resin Composition Solution)

[0088] Preparation was carried out according to the composition shown in Table 1, and the white photosensitive photosensitive resin composition solutions of Examples 1 to 2 and Comparative Example 1 were prepared. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com