Assembly comprising a motor vehicle front beam and two front shock absorbers made of sheet steel

A frontal collision and motor vehicle technology, applied to bumpers and other directions, can solve the problems of increasing the cost of front beams and buffers, difficulties in aluminum processing, and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

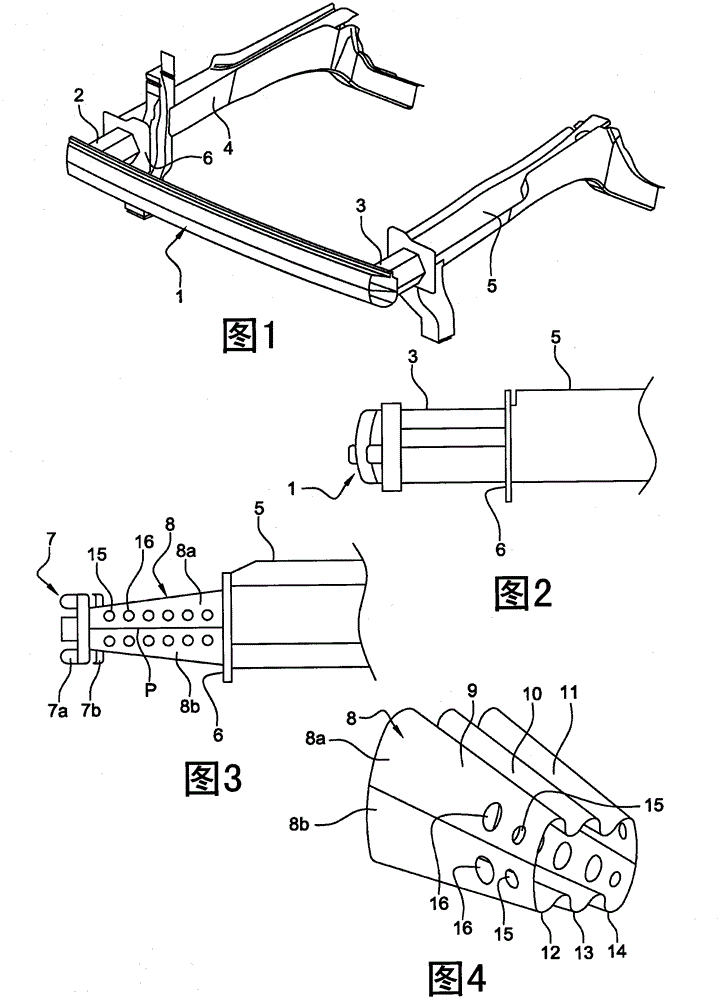

[0033] image 3 The assembly of a front beam 7 and a crash bumper 8 according to the invention fastened to the front of two longitudinal beams 5 is shown, only one of which is visible.

[0034] The front beam 7 consists of two steel plate parts 7a, 7b fixed to each other.

[0035] Such as Figure 4 As shown, each of the two crash bumpers 8 (only one visible) located between the front beam 7 and the plate 6 is constructed of steel plates forming a hollow body expanding from front to rear, the plate 6 is fixed to the two longitudinal beams 5 front.

[0036] According to the invention, the hollow body has undulations 9, 10, 11, 12, 13, 14, the sides of which extend between the front and the rear of the hollow body, i.e. the force generated in the event of a frontal impact. extend in the direction.

[0037] Figure 4 It is also shown that the hollow body is composed of two half-shell-shaped plate parts 8 a , 8 b assembled to each other along the plane of symmetry of the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com