Production process of recombinant protein product

A production process and technology for egg products, which are used in food preparation, yeast-containing food ingredients, and food ingredients as taste improvers, etc. Changes and other problems to achieve the effect of eliminating adverse effects, keeping protein white and reducing salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

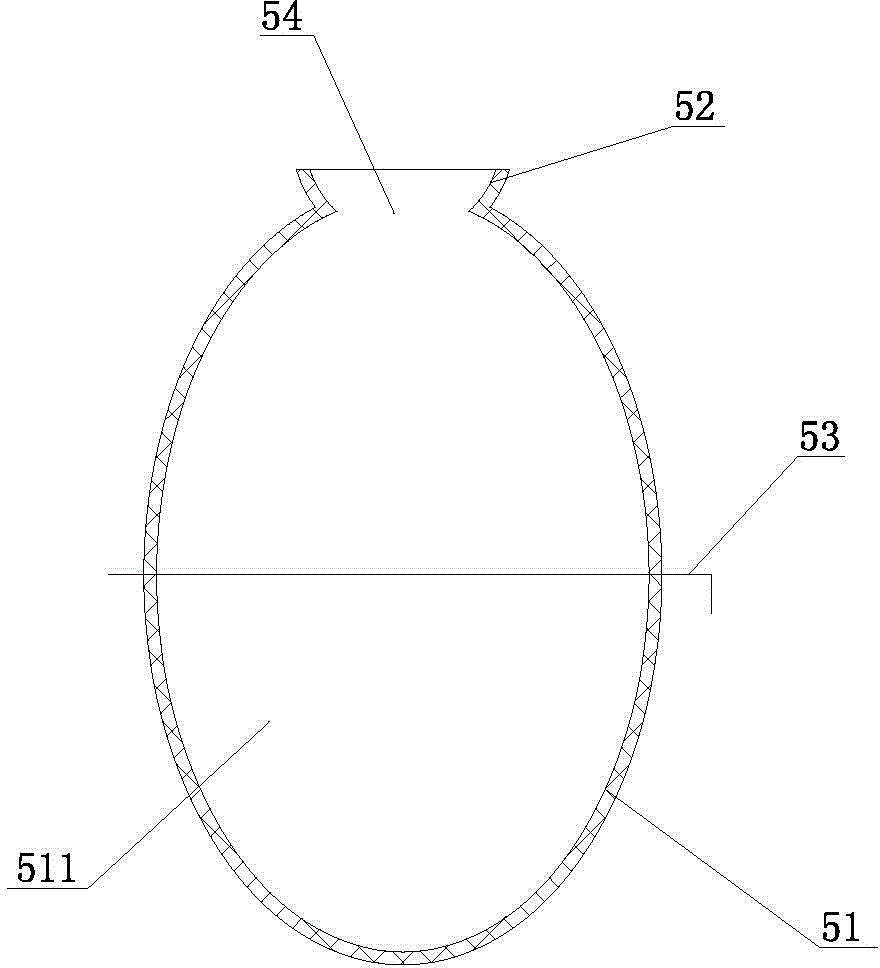

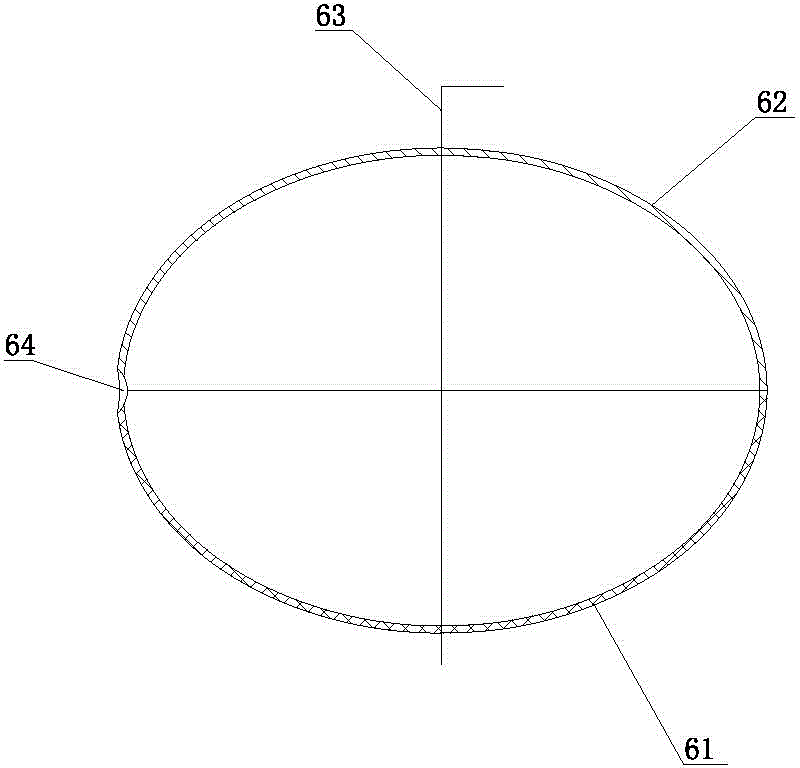

Image

Examples

Embodiment 1

[0039] The production process of recombinant egg products is as follows:

[0040] 1. Scoring eggs: Choose the salted eggs that have been marinated and matured and passed the inspection as raw materials, wash the salted eggs with clean water, dry the surface moisture of the eggshells, break the shells of the salted eggs, take out the salted egg whites and salted egg yolks, and remove them. The eggshell is separated from the salted egg white and salted egg yolk.

[0041]2. Desalination of salted egg white: desalting the separated salted egg white by ultrafiltration. The specific process is: mix salted egg white and water evenly in a ratio of 1: 0.2 (weight ratio), and then use a pump to press it into an ultrafiltration device with a cut-off relative molecular mass of 30,000 for desalination, and then use a cut-off The ultrafiltration membrane with a relative molecular mass of 5,000 performs desalination for the second time, so that the salt content of the salted egg white is re...

Embodiment 2

[0052] The production process of recombinant egg products is as follows:

[0053] 1. Scoring eggs: Choose the salted eggs that have been marinated and matured and passed the inspection as raw materials, wash the salted eggs with clean water, dry the surface moisture of the eggshells, break the shells of the salted eggs, take out the salted egg whites and salted egg yolks, and remove them. The eggshell is separated from the salted egg white and salted egg yolk.

[0054] 2. Desalination of salted egg white: desalting the separated salted egg white by ultrafiltration. The specific process is: mix salted egg white and water evenly at a ratio of 1: 0.6 (weight ratio), and then use a pump to press it into an ultrafiltration device with a cut-off relative molecular mass of 30,000 for desalination, and then use a cut-off The ultrafiltration membrane with a relative molecular mass of 5,000 performs desalination for the second time, so that the salt content of the salted egg white is r...

Embodiment 3

[0064] The production process of recombinant egg products is as follows:

[0065] 1. Scoring eggs: Choose the salted eggs that have been marinated and matured and passed the inspection as raw materials, wash the salted eggs with clean water, dry the surface moisture of the eggshells, break the shells of the salted eggs, take out the salted egg whites and salted egg yolks, and remove them. The eggshell is separated from the salted egg white and salted egg yolk.

[0066] 2. Desalination of salted egg white: desalting the separated salted egg white by ultrafiltration. The specific process is: mix salted egg white and water evenly in a ratio of 1: 1.2 (weight ratio), and then use a pump to press it into an ultrafiltration device with a cut-off relative molecular mass of 30,000 for desalination, and then use a cut-off The ultrafiltration membrane with a relative molecular mass of 5,000 performs desalination for the second time, so that the salt content of the salted egg white is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com