Composite filter tip for heating type non-combustion cigarette

A heat-not-burn and tip-stick technology, which is applied in the fields of tobacco, application, e-liquid filter elements, etc., can solve problems such as insufficient smoke volume, long response time, and poor smoking experience of non-burning cigarettes, so as to improve the sensory quality of smoking, Effects of increasing smoke volume and shortening smoke response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

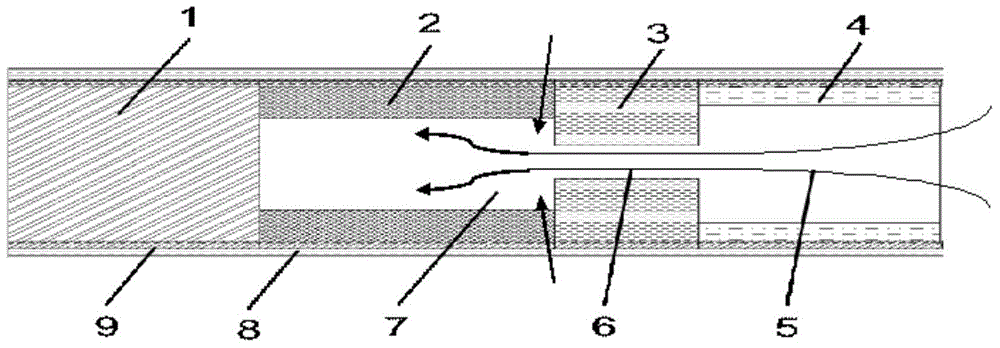

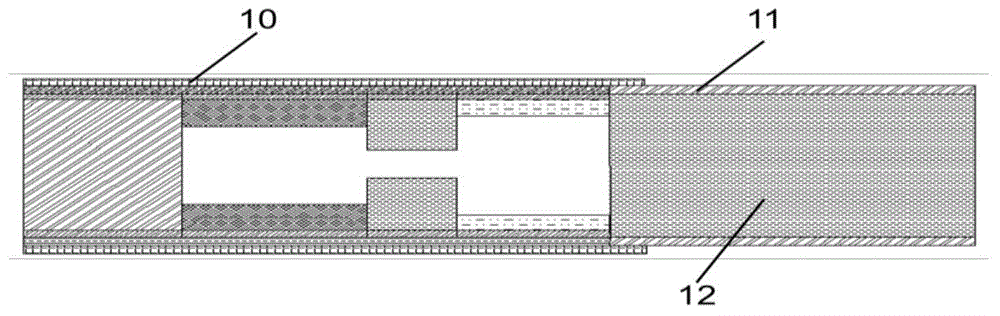

[0030] Such as figure 1 A composite mouthpiece for heat-not-burn cigarettes is shown, which includes the following segments connected in sequence: solid filter 1, first hollow filter 2, second hollow filter 3, third hollow filter 4, wherein each segment is respectively wrapped by the first forming paper 9 of the same material, and is compositely formed by the second forming paper 8 located at the outermost layer of the composite nozzle rod; wherein the hollow part of the first hollow filter 2 is the fourth Cavity 7, the hollow part of the third hollow filter 4 is the sixth cavity 5, and the passage between the fourth cavity 7 and the sixth cavity 5 is located in the hollow part of the second hollow filter 3 The fifth cavity 6 is in gas flow communication. The length of the composite nozzle rod is 40mm, wherein the length of each segment is 10mm, and the outer diameter is 7.8mm. figure 1 The horizontal arrows in the middle indicate the flow direction of smoke under the Ventur...

Embodiment 2

[0038] Embodiment 2: smoke release performance evaluation

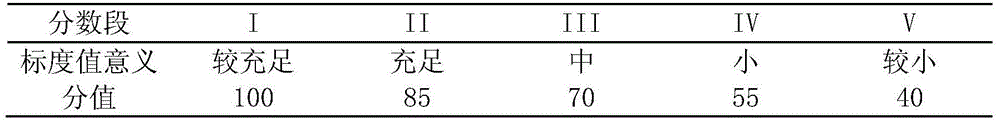

[0039] Using the electric heating type cigarettes in Example 1 of the present invention, a certain brand of traditional cigarettes and the existing electric heating type cigarettes to carry out the smoke release performance comparison test, the smoke release performance evaluation scores are set as shown in Table 1:

[0040] Table 1: Score setting for smoke release performance evaluation

[0041]

[0042] Inspection procedure: provide samples and inspection sheets to the evaluation experts, and require the evaluation staff to evaluate the indicators according to the requirements of the form.

[0043] Result statistics: The evaluation results of all appraisers are valid, and the arithmetic mean of the evaluation results of each appraiser is calculated, and the result is rounded to one decimal place. The evaluation results are shown in Table 2:

[0044] Table 2: Comparison table of smoke release performance evaluat...

Embodiment 3

[0050] Embodiment 3: sensory quality evaluation

[0051] Using the electric heating type cigarette in Example 1 of the present invention and the existing special electric heating type cigarette to carry out the sensory quality evaluation comparison test (the two types of cigarettes use the same tobacco material), the sensory quality evaluation scores are set as in Table 4 Shown:

[0052] Table 4: Evaluation criteria for sensory quality of new cigarettes

[0053]

[0054] Inspection procedure: Provide samples and inspection forms to the evaluation experts, and require the evaluation staff to evaluate various indicators according to the requirements of the form.

[0055] Result statistics: The evaluation results of all appraisers are valid. Calculate the arithmetic mean of the individual evaluation results of each appraiser, keep the result to one decimal place, and add the arithmetic mean of each individual item to get the total score , the results are kept to one decimal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com