Medical rotary cutter control system

A technology of control system and rotary cutter, which is applied in the field of medical equipment, can solve the problems of increasing the probability of injury to the human body by the rotary cutter head, the extraction time is not fixed, and staying in the pipeline, etc. It is easy to promote and use, simple in structure, The effect of avoiding harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

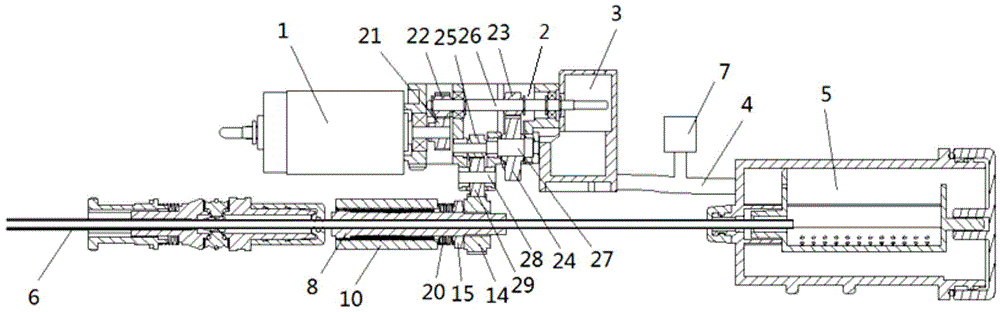

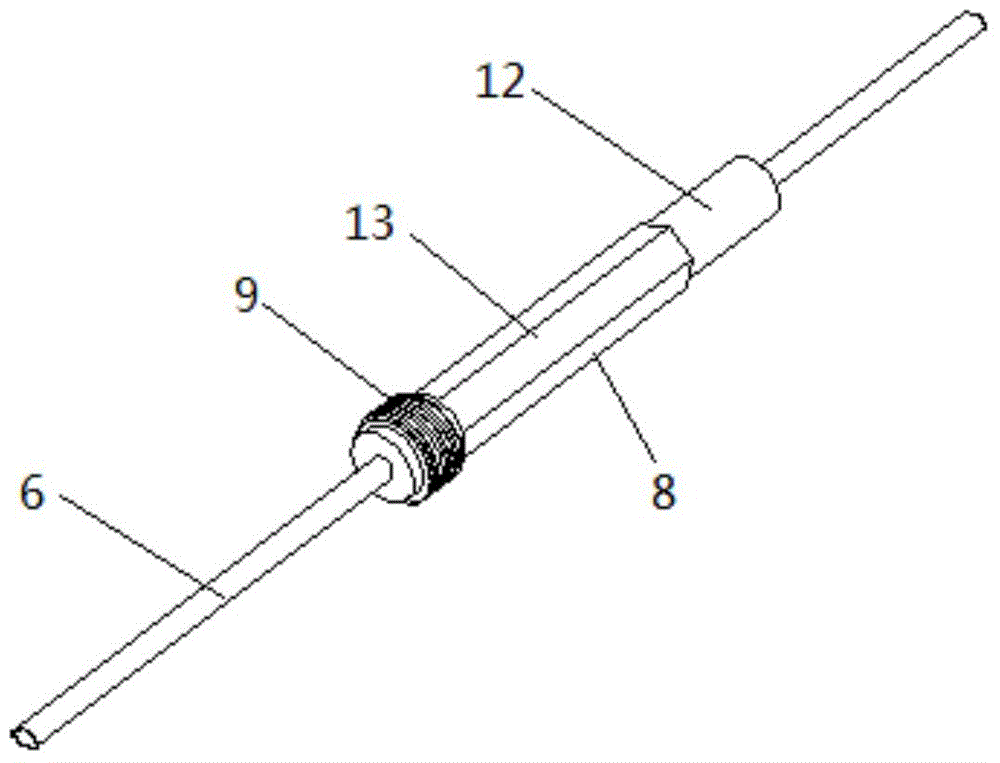

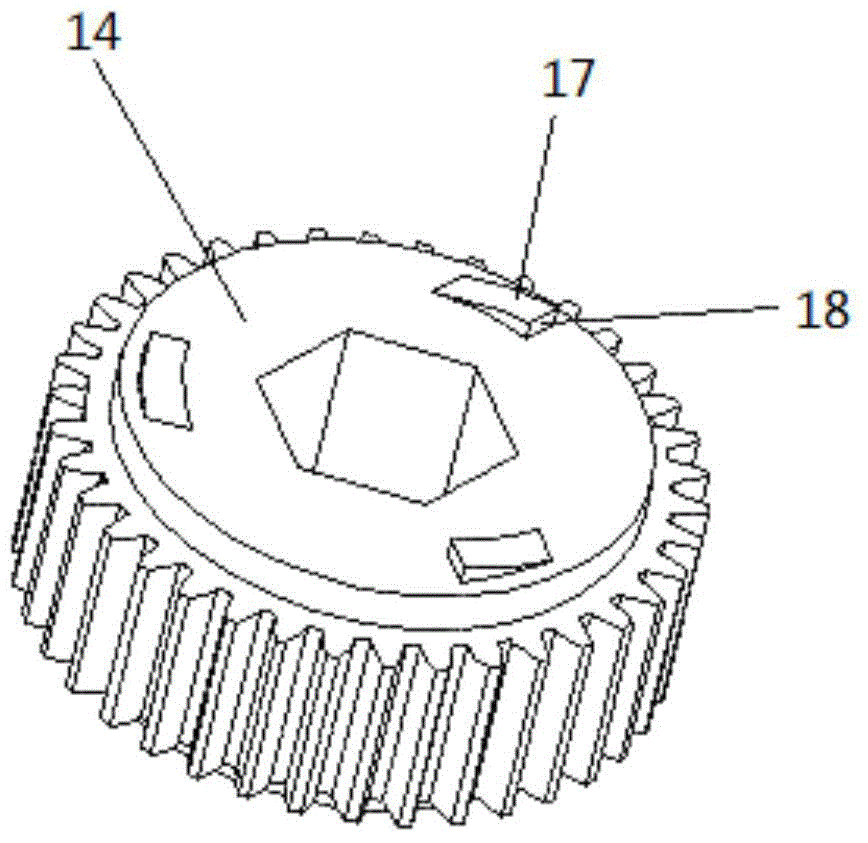

[0029] see Figure 1-2 , a medical rotary cutter control system, which includes a motor 1, the output end of the motor 1 is provided with a splitter 2 for dividing the output power of the motor 1 into two transmissions, wherein the first transmission drives a vacuum pump 3 rotation, the suction end of the vacuum pump 3 communicates with the sample chamber 5 through the pipeline 4, the second transmission drives the rotary cutter tube 6 to rotate, and the rotary cutter tube 6 is set to cooperate with the second transmission and A clutch device suitable for cutting off the transmission when the rotary cutter tube 6 has been rotary-cut. The medical rotary cutter control system of this embodiment sets a clutch device between the second transmission and the rotary cutter. The transmission is disconnected under the action of the vacuum pump. At this time, the power of the second transmission cannot be transmitted to the rotary cutter tube, and the rotary cutter head is in a static ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com