Special mechanical hand capable of grabbing multiple parts simultaneously

A manipulator, multi-part technology, applied in metal processing and other directions, can solve the problem of not being able to grasp multiple parts at the same time, and achieve the effects of simple structure, improved production efficiency, and convenient and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

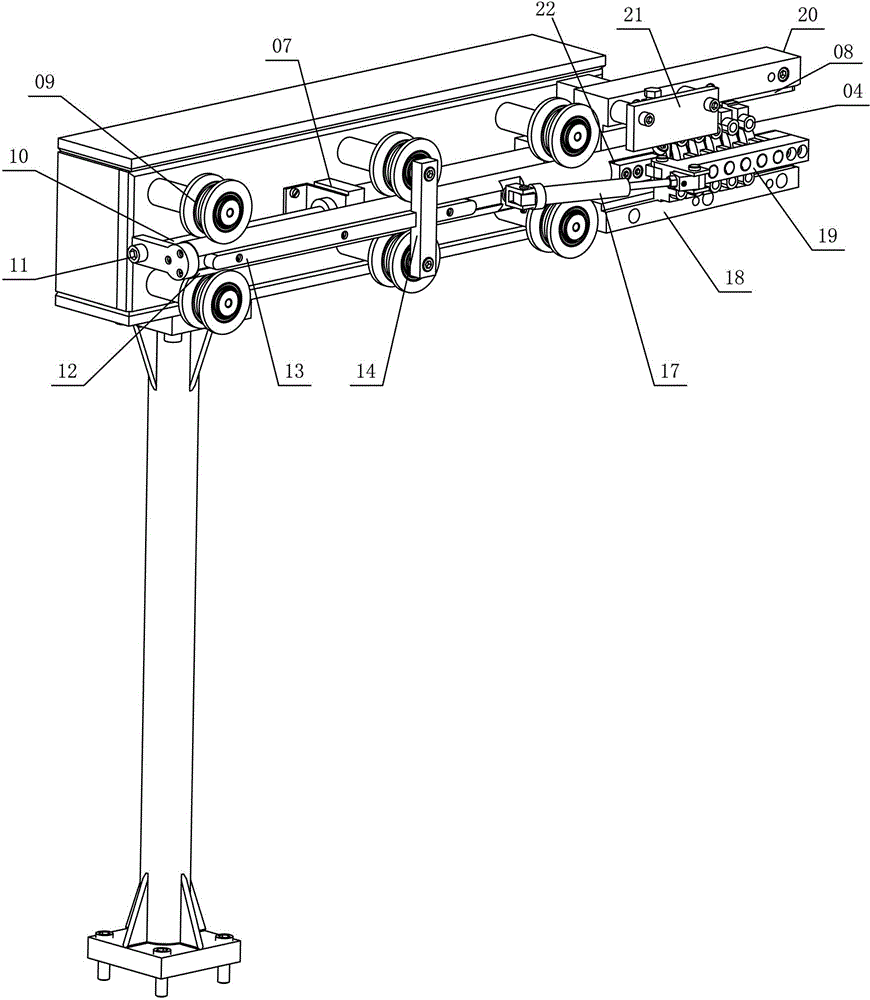

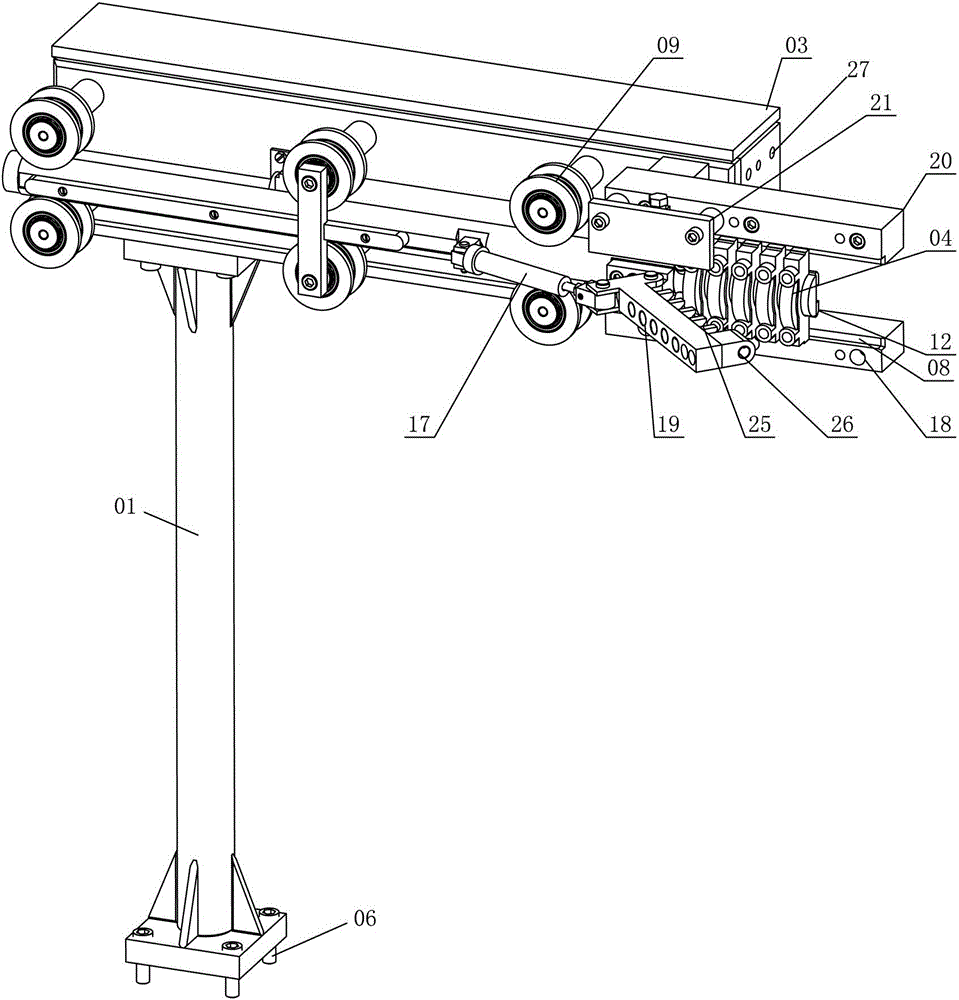

[0013] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

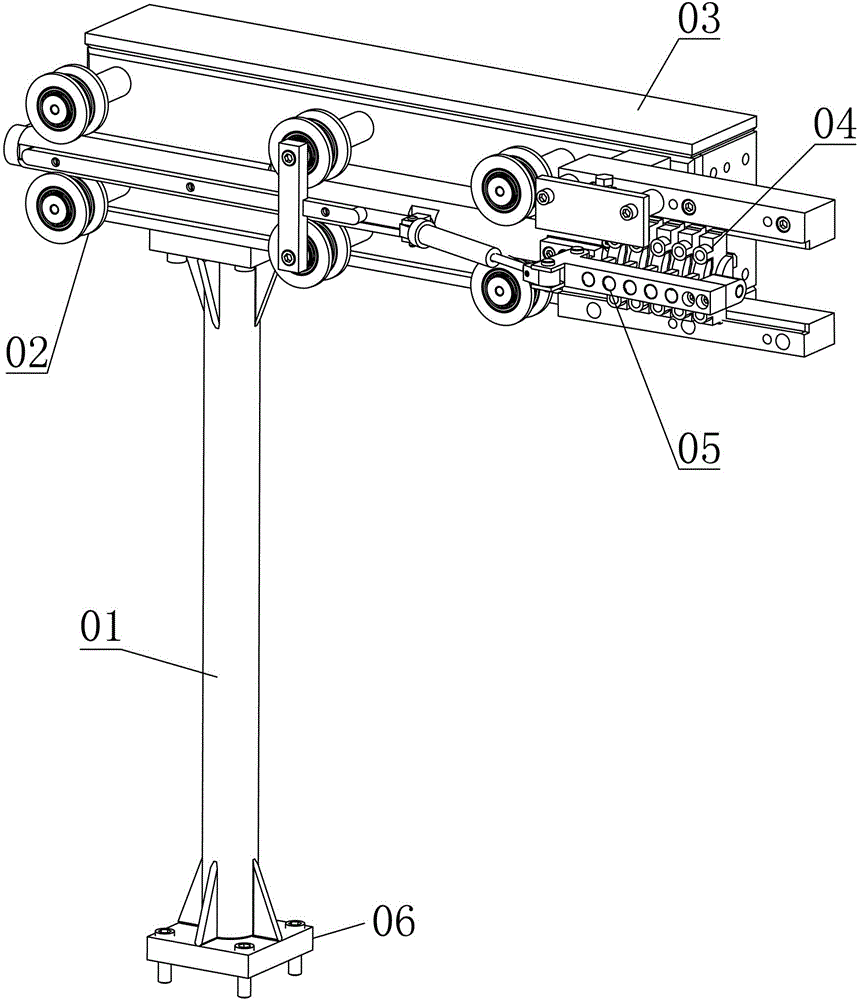

[0014] Such as figure 1 As shown, the present invention includes a support system 01 and a manipulator overall frame 03 supported by the support system 01. The manipulator overall frame 03 is provided with a conveying in and out roller system 02 and a part positioning floating clamping system 05. The conveying in and out roller system 02 is used for conveying in and out of parts 04, and the part positioning floating clamping system 05 is used for clamping and positioning of parts 04.

[0015] The conveying in and out roller system 02 includes a conveying rod 12 that can move laterally and is arranged on the overall frame 03 of the manipulator. The front portion of the bar 12 is fixed with a positioning block 22 .

[0016] The part positioning floating clamping system 05 includes an upper positioning plate 20 and a low...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap