A method and device for full-profile grinding of tenon blades using cylindrical coordinate three-axis linkage machine tools

A technology of three-axis linkage and cylindrical coordinates, which is applied in the direction of grinding drive device, grinding machine parts, grinding workpiece support, etc., can solve the problems of unfavorable blade working strength, reduced blade processing cost, energy and workshop consumption, etc. Achieve the effects of improving machine tool production efficiency, reducing plant size, and reducing machine tool costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

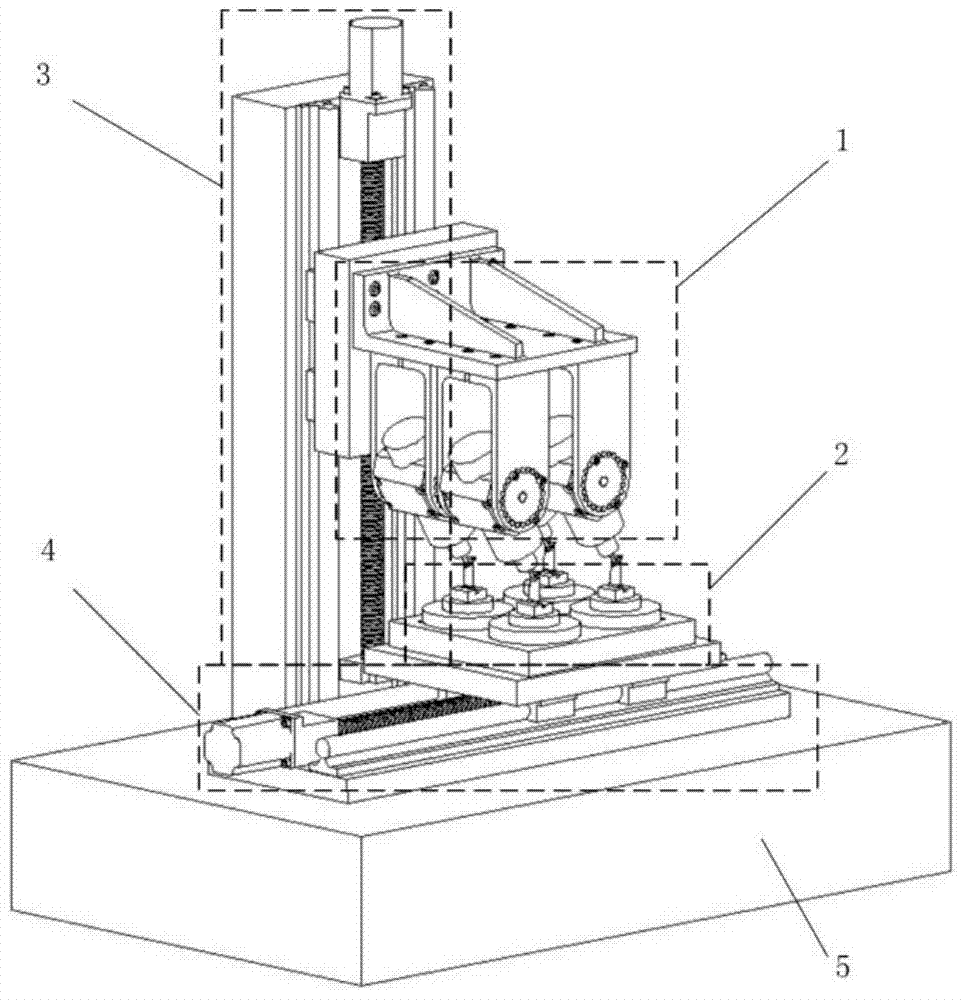

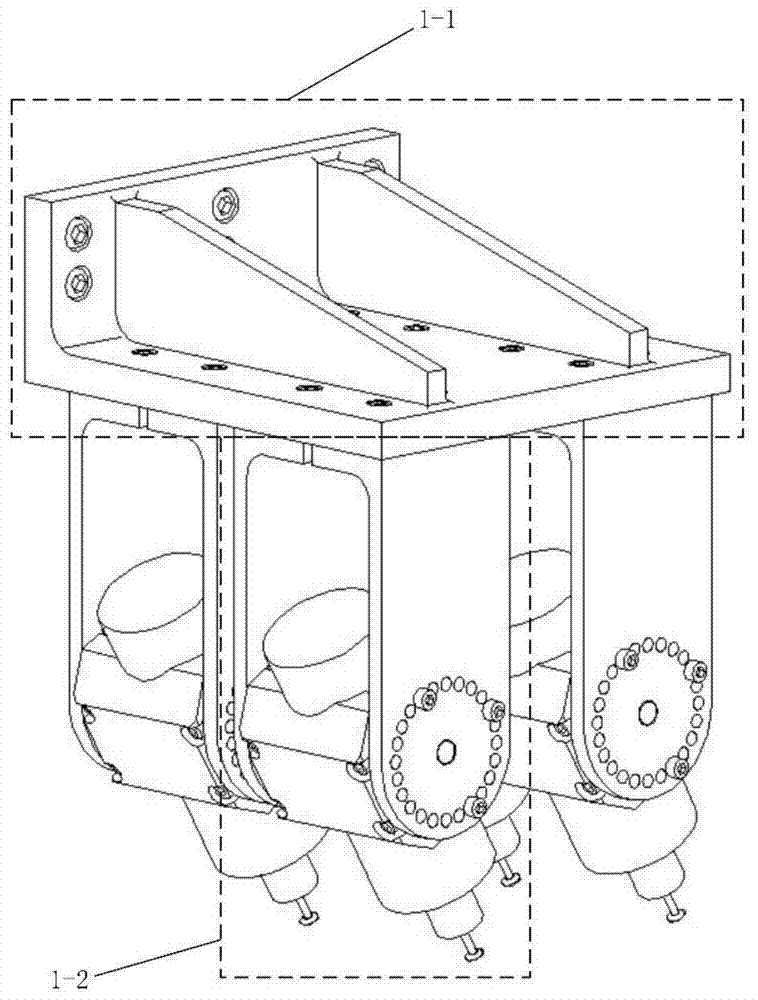

[0039] See figure 1 — Figure 9 , the embodiment of the present invention is described below in conjunction with accompanying drawing.

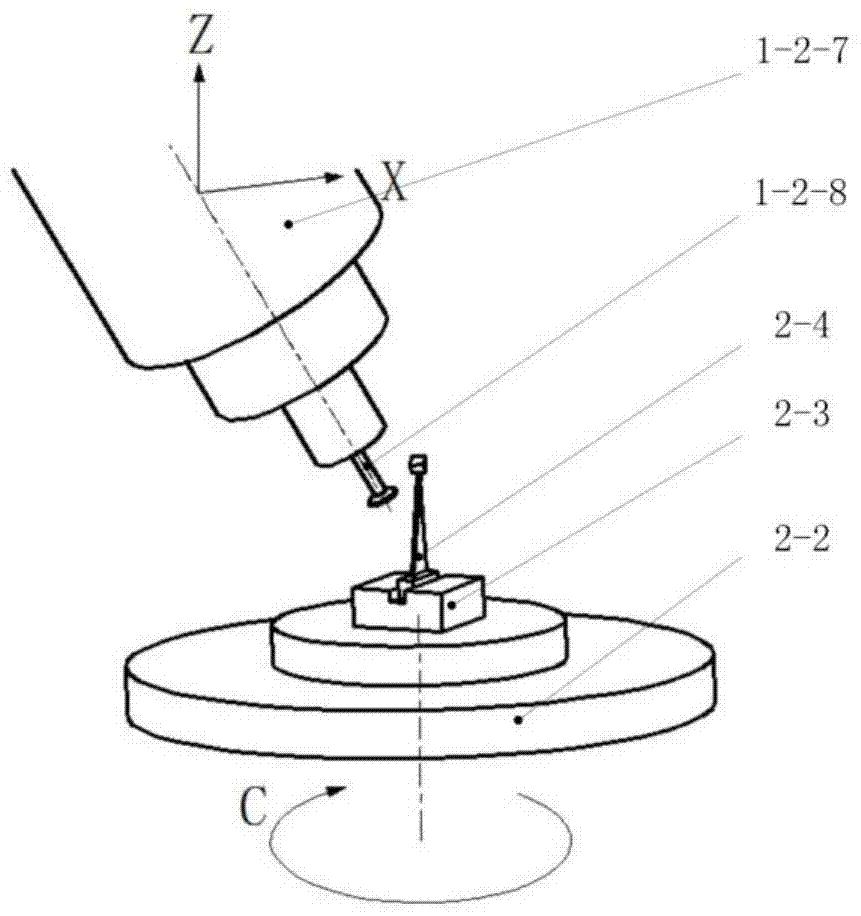

[0040] Such as Figure 5 As shown, the four blades 2-4 are installed on the four fixtures 2-3 of the CNC machine tool in an array with the tenons facing upwards, so as to ensure that the length direction of the blade body of the blades 2-4 is consistent with that of the rotary table 2-2 or the rotary shaft. The direction of the axis is basically the same, especially to ensure that the mortise edge plate is as parallel as possible to the horizontal plane. The fixture 2-3 array is installed on the workbench 2-2, and the turntable is driven by the same motor, which can realize synchronous rotation.

[0041] Such as Figure 4 Combined with the structural form of the blade 2-4 as shown, select a suitable disc-shaped grinding wheel 1-2-8 whose rod diameter is smaller than the diameter of the grinding wheel and install it on the main shaft 1-2-7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com