Waste heat recycling and baking device of energy-saving environment-friendly injection machine

A waste heat recovery, energy saving and environmental protection technology is applied in the field of heat source recovery and utilization devices, which can solve the problems of clogging of the drying barrel, inability to realize the movable operation of the staff, trouble, etc., and achieve the effects of simple structure, efficient utilization of waste heat, and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

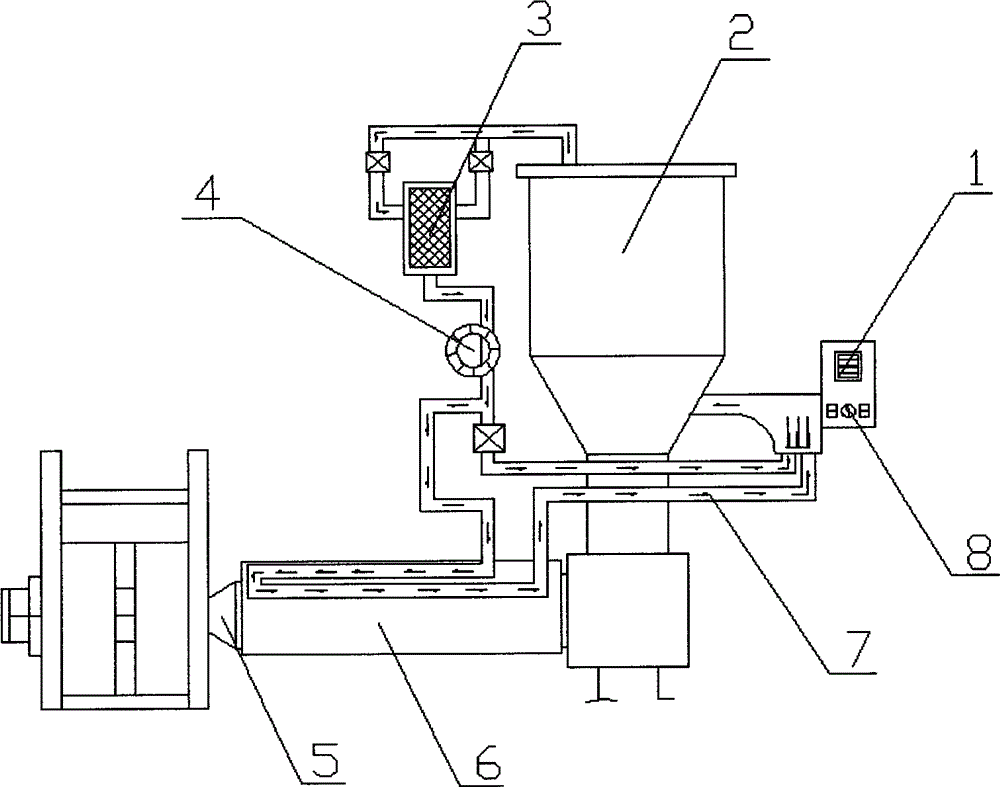

[0011] Such as figure 1 As shown, an energy-saving and environment-friendly injection molding machine waste heat recovery drying device, the device includes a temperature control box 1, a drying barrel 2, a filter 3, an air pump 4, an injection molding machine barrel 5, a heat collecting device 6 and a remote control , the drying material barrel 2, the filter 3 and the air pump 4 are connected through the gas delivery pipeline 7, the temperature control box 1 is arranged on the right side of the drying material barrel 2, and the temperature control box 1 is provided with an inductor 8, the Inductor 8 can receive the instruction that remote controller sends, and described remote controller is provided with magnetic block, and when not in use, remote controller can be adsorbed on the equipment, is not easy to lose, and described heat collecting device 6 is provided with stainless steel heat collecting tube, relatively The adjacent stainless steel heat collecting tubes are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com