a carbon fiber tube

A technology of carbon fiber tubes and carbon fibers, which is applied in the application field of carbon fiber materials, can solve the problems of loose bonding of carbon fiber cloth layers, low bonding degree, scrapping of carbon fiber tubes, etc., so as to reduce the probability of creases, increase the degree of bonding, and enhance the degree of bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

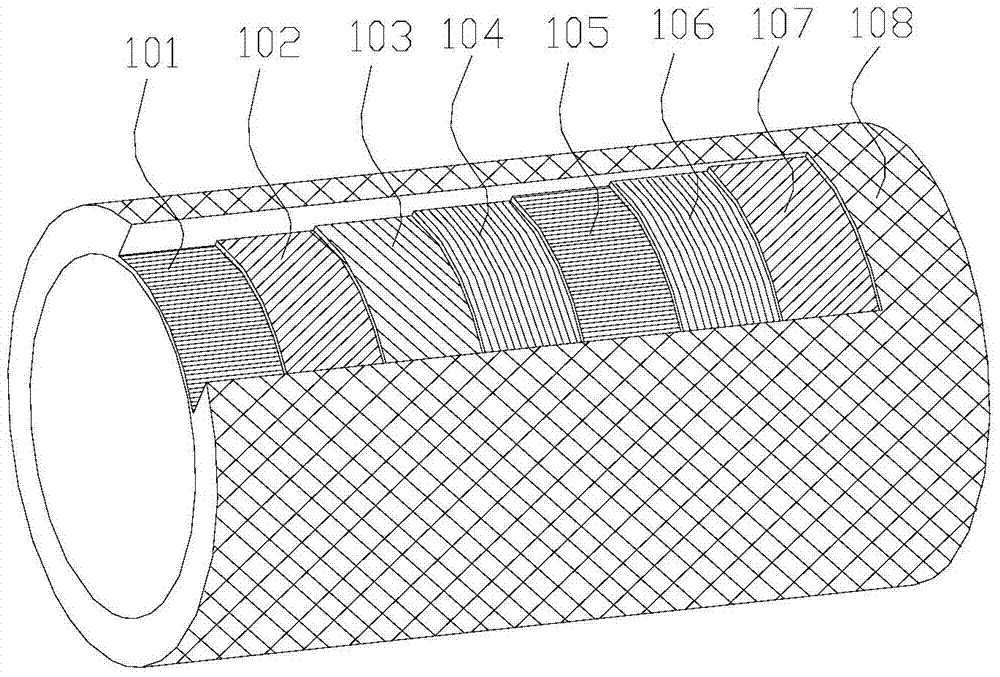

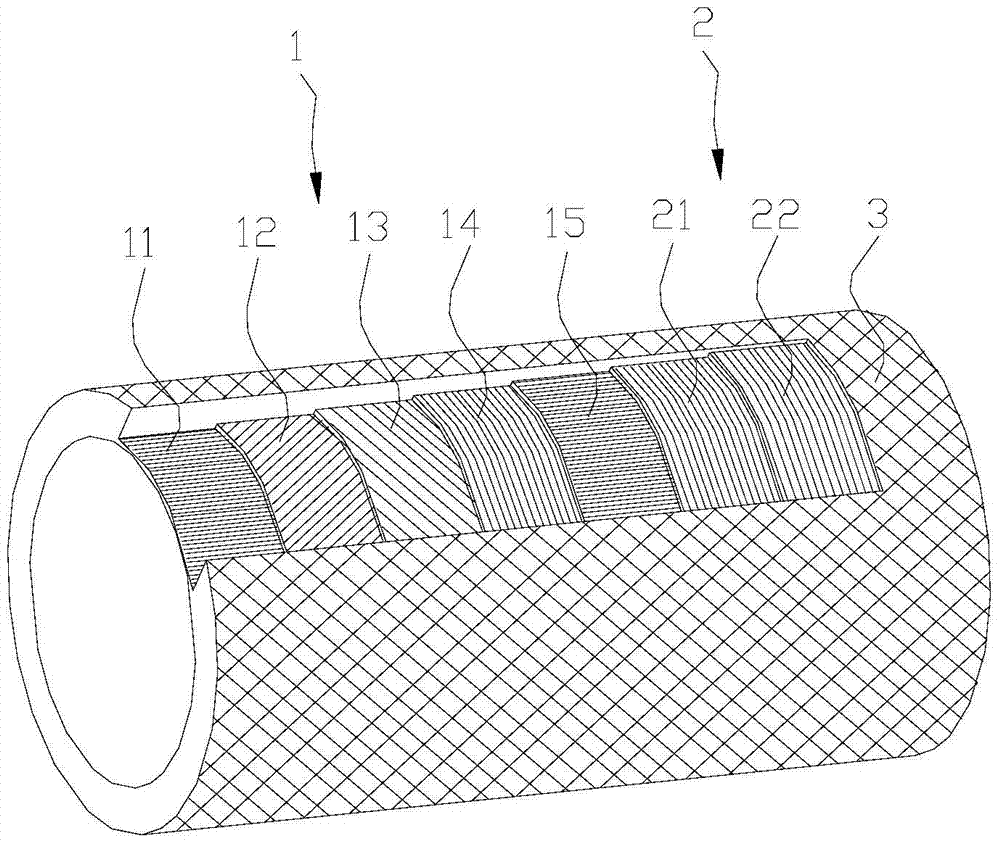

[0019] refer to image 3 , a carbon fiber tube, comprising a carbon fiber module layer 1, a basalt fiber module layer 2, and a carbon fiber cloth layer 3 wrapped from inside to outside layers, the basalt fiber module layer 2 includes at least two layers of basalt fiber cloth layers, the carbon fiber The carbon fiber tows of the cloth layer 3 are arranged in a staggered manner to form a staggered mesh 31 .

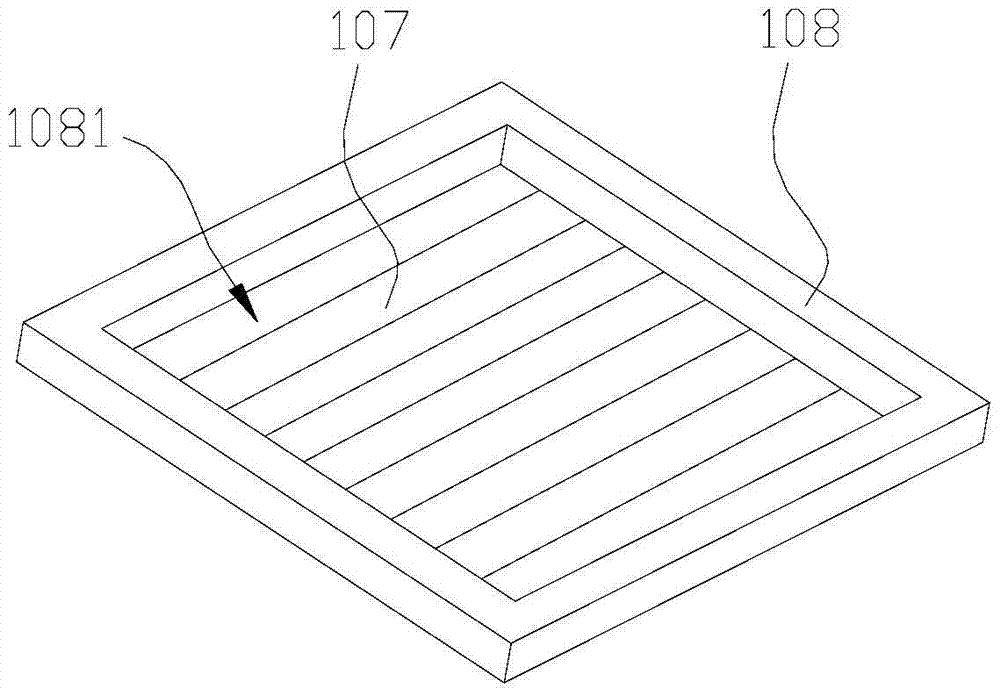

[0020] In the present invention, the carbon fiber module layer, the basalt fiber module layer and the carbon fiber cloth layer are wrapped successively from the inner layer to the outer layer, and the carbon fiber cloth layer is closely attached to the seventh basalt fiber cloth layer in the basalt fiber module layer. Figure 4 , due to the better softness of basalt fiber material, even if there are local protrusions formed on the carbon fiber cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com