Fuel oil filling pipe assembly

A fuel pipe and fuel technology, applied in the field of vehicle accessories, can solve the problems of small sealing contact surface, high processing cost, complex structure, etc., and achieve the effects of good sealing performance, simple structure and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

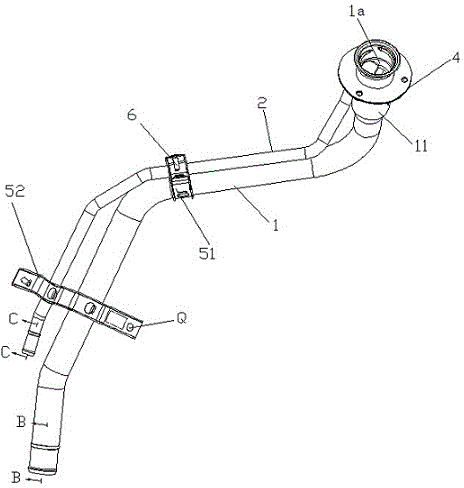

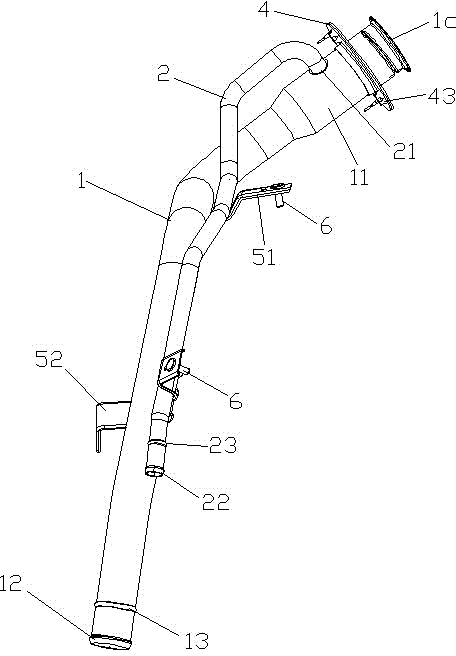

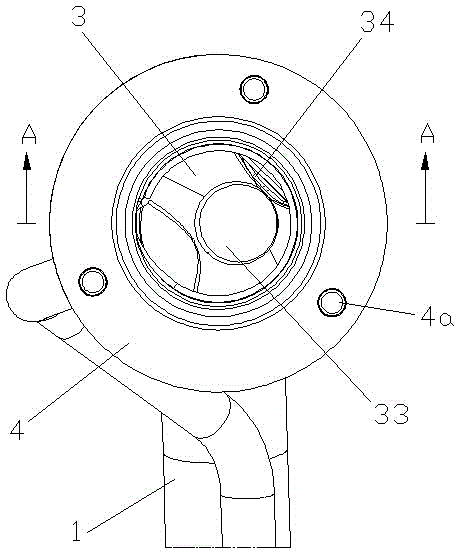

[0021] Figure 1 to Figure 6 It is a structural schematic diagram of the present invention.

[0022] The reference signs are: anti-overflow chamber K, assembly hole Q, oil filling pipe 1, oil filling chamber 1a, inner circular sealing inclined surface 1b, arc surface 1c, internal thread 1d, oil filling end 11, oil outlet connecting convex mouth 12, Refueling pipe annular bead 13, air outlet pipe 2, air outlet end 21, air intake connection convex nozzle 22, air outlet pipe annular bead 23, overflow prevention sleeve 3, round pipe part 31, constriction part 32, round pipe refueling port 33, lock Tightening piece 34, connecting flange assembly 4, bolt hole 4a, stainless steel flange plate 41, anti-off button hole 41a, gasket 42, anti-off positioning button 42a, spot welding nut 43, first bracket 51, second Support 52, spot welding bolt 6.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com