Internal suction integrated flameout protection frying stove

A flameout protection, integrated technology, applied in the field of frying stoves, can solve the problems of waste of energy, insufficient combustion of gas, uneven mixing, etc., to achieve the effect of improving safety and service life, sufficient combustion of gas, and good mute effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

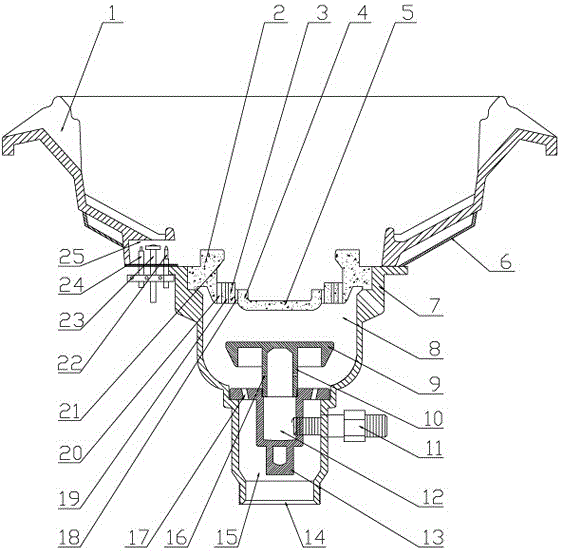

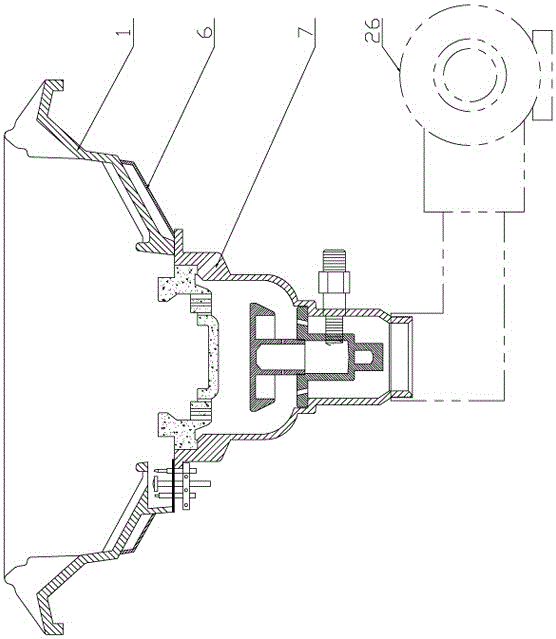

[0015] see figure 1 , figure 2 , the present invention is a kind of internal suction integrated flameout protection frying stove, which has a furnace shell 7, a furnace plate 5 is installed in the middle of the top of the furnace shell, the periphery of the furnace plate is located on the upper part of the furnace shell, and a furnace 1 is provided, and the bottom of the furnace shell is provided with Air inlet 14, a cyclone diversion head 13 is installed in the middle of the lower part of the furnace shell, a mixing chamber 8 is formed between the cyclone diversion head and the furnace plate, an air collection chamber 15 is formed between the cyclone diversion head and the air inlet, and the cyclone diversion The outer periphery of the top of the head is provided with a number of evenly distributed air guide holes 17, and the middle of the cyclone guide head is a downwardly recessed structure to form a gas collection chamber 12. The side wall of the gas collection chamber is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com