Leakage test mechanism used for built-in products and test method thereof

A technology for testing institutions and products, which is applied in the direction of using liquid/vacuum for liquid tightness measurement, and by measuring the acceleration and deceleration rates of fluids. cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

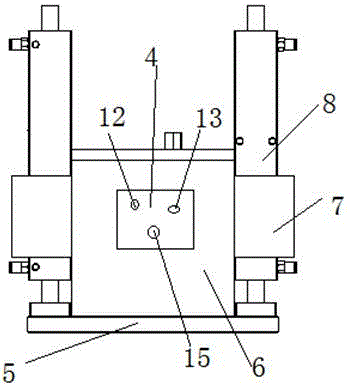

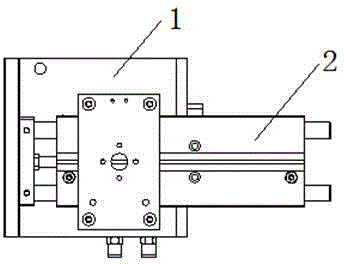

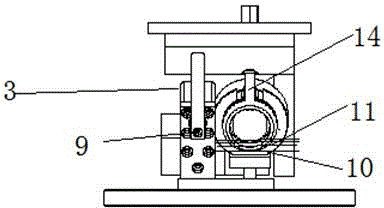

[0041] As shown in the figure, a leak test mechanism for built-in products includes: a sealing mechanism 1, a cavity motion system 2, a product clamping system 3, a test execution system 4 and a control system, and the sealing mechanism 1 is composed of a sealing cover The plate 5 and the sealed cavity 6 are composed, the cavity motion system 2 is composed of a stepping motor linkage mechanism 7 and a sealing cover cylinder motion mechanism 8, and the product clamping system 3 includes a fixed product cylinder 9, a fixed product clamp 10 and product 11 , the test execution system 4 includes a pressure transmitter 12 , a standard leakage hole interface 13 , a product leakage nozzle 14 and an air inlet valve 15 .

[0042] The relationship between the above components is as follows:

[0043] The sealing cover 5 is provided with a countersunk via hole 51 and a positioning hole 52, wherein the positioning hole 52 is arranged on the back side of the sealing cover 5, and it cannot be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com