Water-cooling radiating device used for 110kV thyristor valve body

A thyristor valve body, water-cooled heat dissipation technology, applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problems of inconvenient installation of thyristors, affecting partial discharge level, and complicated water connection of devices, etc., to achieve flow Excellent thermal resistance matching characteristics, uniform potential distribution, and easy maintenance and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

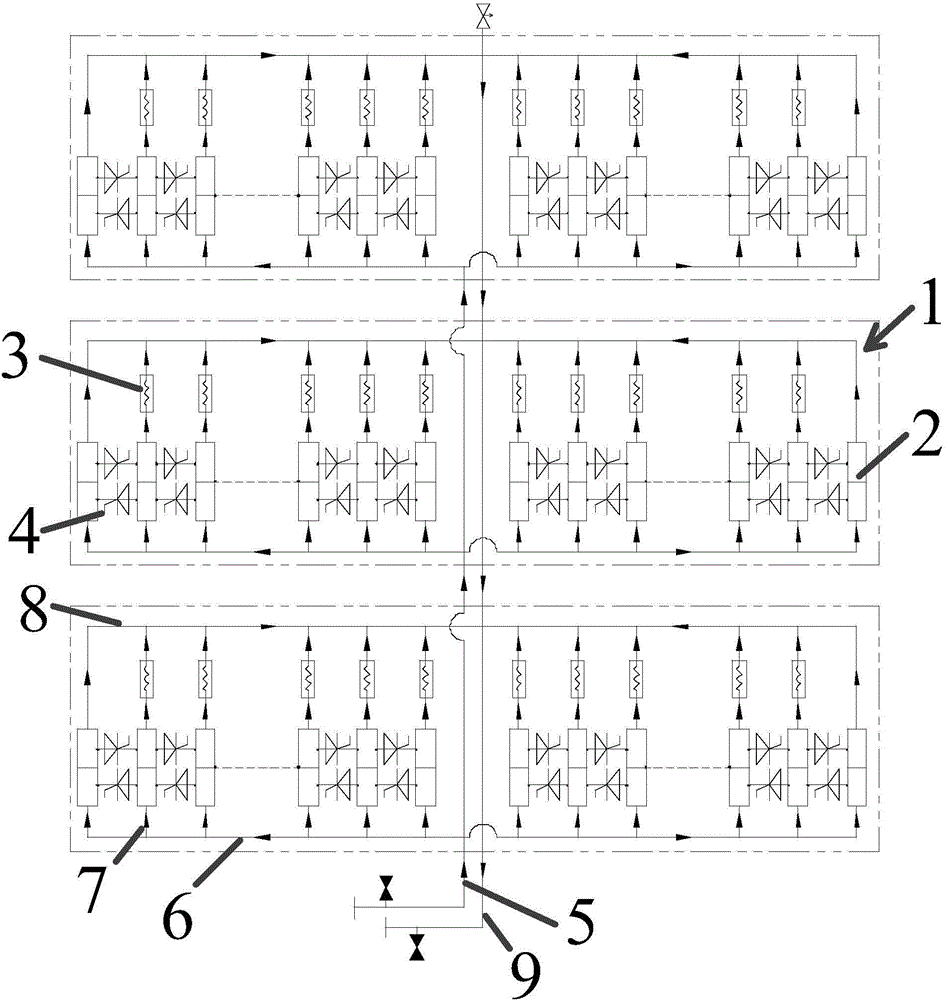

[0044] Such as figure 1 As shown, a water-cooling heat dissipation device for a 110kV thyristor valve body is provided. The thyristor 4 is a rectangular switching element with a semiconductor device inside. A rectangular heat dissipation pipe composed of a plurality of heat dissipation assemblies 2 arranged in parallel in the assembly 1;

[0045] The heat dissipation assembly 2 is a cuboid composed of heat dissipation elements 19 connected in series and connected to the thyristor 4 on both sides.

[0046] Such as figure 1 As shown, the water pipe assembly 1 is a rectangular water pipe composed of successively connected water inlet pipe 5, water inlet branch pipe 6, water distribution pipe 7, return water branch pipe 8 and return water pipe 9;

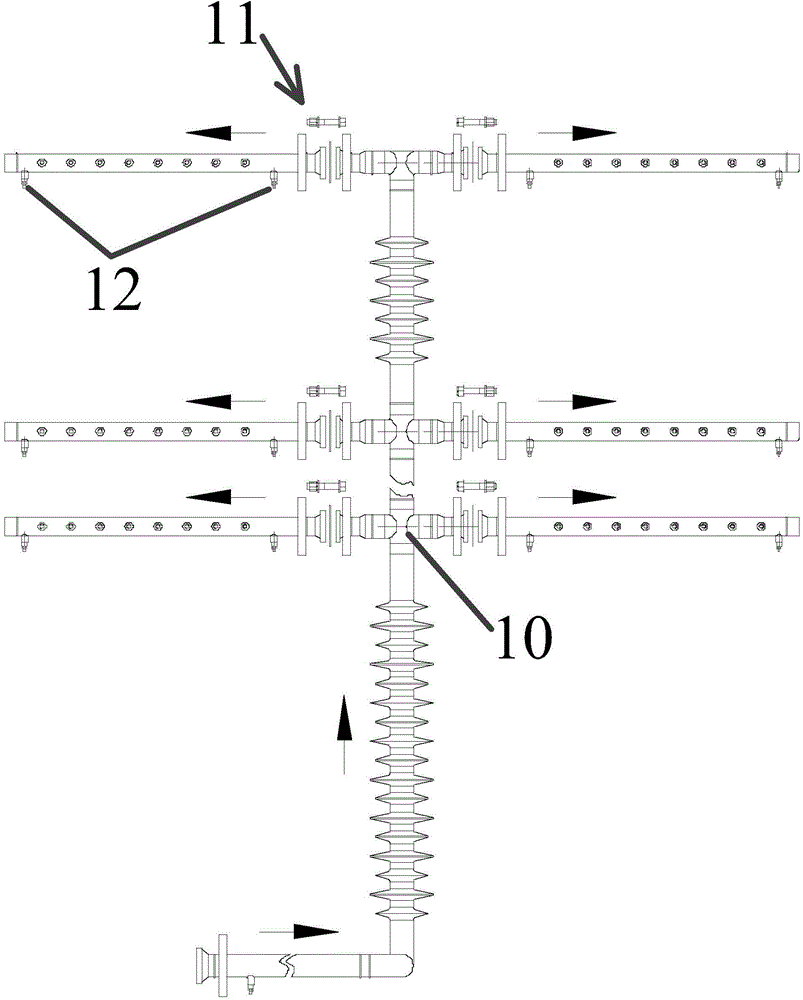

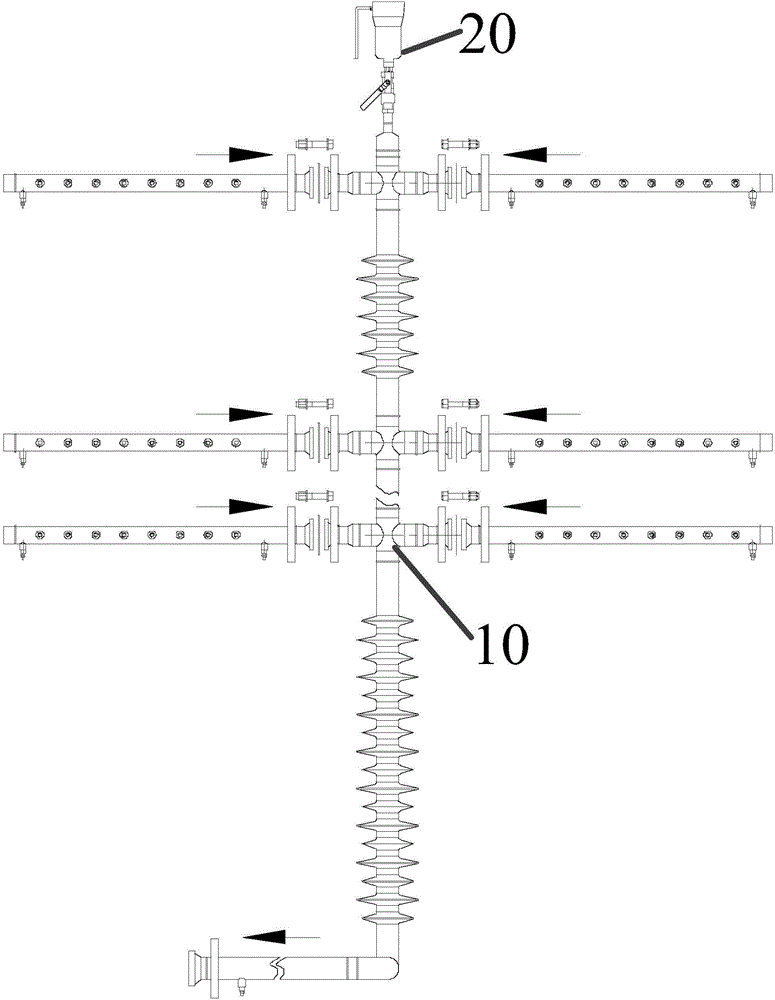

[0047] Such as figure 2 As shown, the water inlet pipe 5 is L-shaped, and its vertical pipe is in the shape of an umbrella skirt and is flexibly connected to the center of the water inlet branch pipe 6 through a pipe interface 10; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com