Packaging structure and packaging method for rectifier bridge with high thermal conductivity and high insulation and voltage resistance

A packaging method and packaging structure technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of reduced insulation degree, glass fiber cloth damage, high copper material requirements, etc., to improve insulation The effect of withstand voltage, improve the withstand voltage insulation, and simplify the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

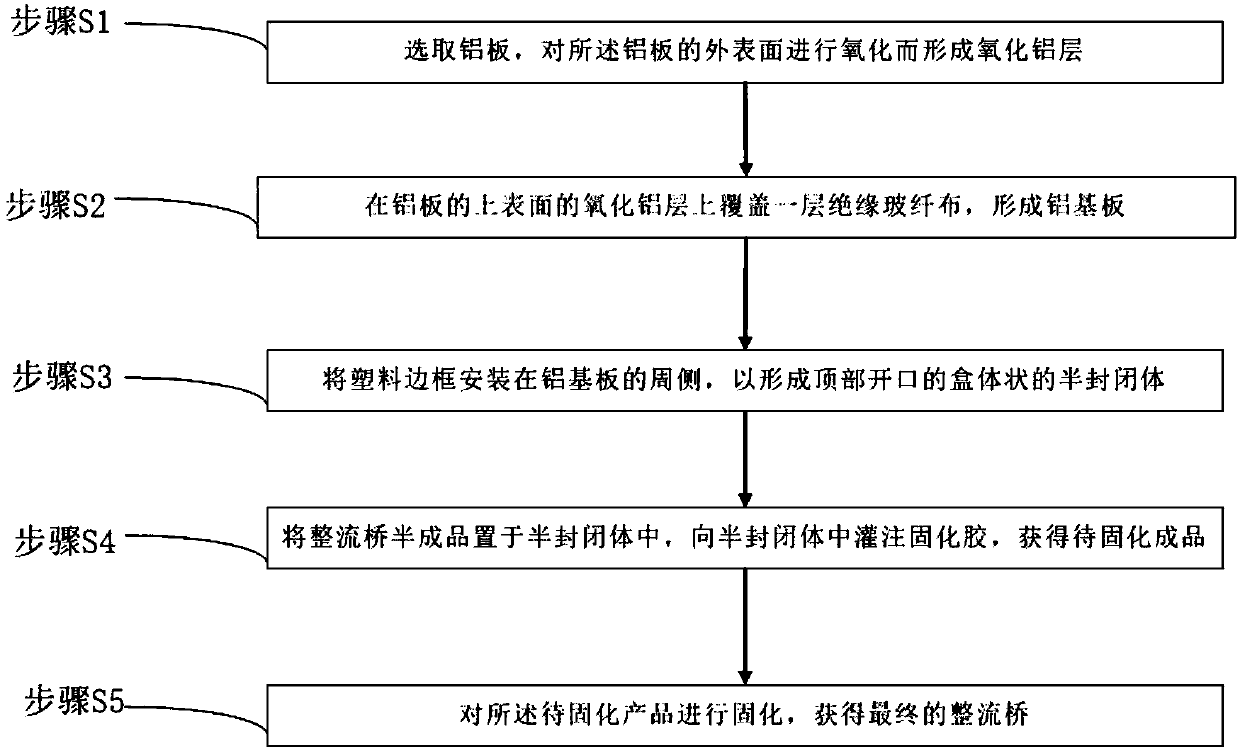

[0055] The rectifier bridge of this embodiment is prepared by the following steps:

[0056] 1. Select an aluminum plate, and oxidize the outer surface of the aluminum plate to form an aluminum oxide layer;

[0057] 2. Cover the aluminum oxide layer with a layer of insulating glass fiber cloth to form an aluminum substrate, wherein the thickness of the insulating glass fiber cloth is 0.15mm, and coat between the alumina layer and the insulating glass fiber cloth Covered with an epoxy resin layer, the insulating glass fiber cloth is adhered to the alumina layer by high-temperature lamination, the thickness of the epoxy resin layer is 50 μm, and the temperature of the high-temperature lamination is 160°C;

[0058] 3. Install the plastic frame on the peripheral side of the aluminum substrate to form a box-shaped semi-closed body with an open top;

[0059] 4. Install the rectifier bridge semi-finished product in the semi-closed body, pour curing glue into the semi-closed body, so ...

Embodiment 2

[0068] The rectifier bridge of this embodiment is prepared by the following steps:

[0069] 1. Select an aluminum plate, and oxidize the outer surface of the aluminum plate to form an aluminum oxide layer;

[0070] 2. Cover the aluminum oxide layer with a layer of insulating glass fiber cloth to form an aluminum substrate, wherein the thickness of the insulating glass fiber cloth is 0.18mm, and coat between the alumina layer and the insulating glass fiber cloth Covered with an epoxy resin layer, the insulating glass fiber cloth is adhered to the alumina layer by high-temperature lamination, the thickness of the epoxy resin layer is 100 μm, and the temperature of the high-temperature lamination is 170°C;

[0071] 3. Install the plastic frame on the peripheral side of the aluminum substrate to form a box-shaped semi-closed body with an open top;

[0072] 4. Install the rectifier bridge semi-finished product in the semi-closed body, pour curing glue into the semi-closed body, so...

Embodiment 3

[0081] The rectifier bridge of this embodiment is prepared by the following steps:

[0082] 1. Select an aluminum plate, and oxidize the outer surface of the aluminum plate to form an aluminum oxide layer;

[0083] 2. Cover the aluminum oxide layer with a layer of insulating glass fiber cloth to form an aluminum substrate, wherein the thickness of the insulating glass fiber cloth is 0.2mm, and coat between the alumina layer and the insulating glass fiber cloth Covered with an epoxy resin layer, the insulating glass fiber cloth is adhered to the alumina layer by high-temperature lamination, the thickness of the epoxy resin layer is 150 μm, and the temperature of the high-temperature lamination is 180°C;

[0084] 3. Install the plastic frame on the peripheral side of the aluminum substrate to form a box-shaped semi-closed body with an open top;

[0085] 4. Install the rectifier bridge semi-finished product in the semi-closed body, pour curing glue into the semi-closed body, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com