Array substrate, manufacture method thereof, and display device

A technology of an array substrate and a manufacturing method, applied in the display field, can solve the problems of prone to faults, pixel electrodes 7 providing data signals, reducing the yield of array substrate products, etc., so as to ensure display effect, improve product yield, and optimize connection conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

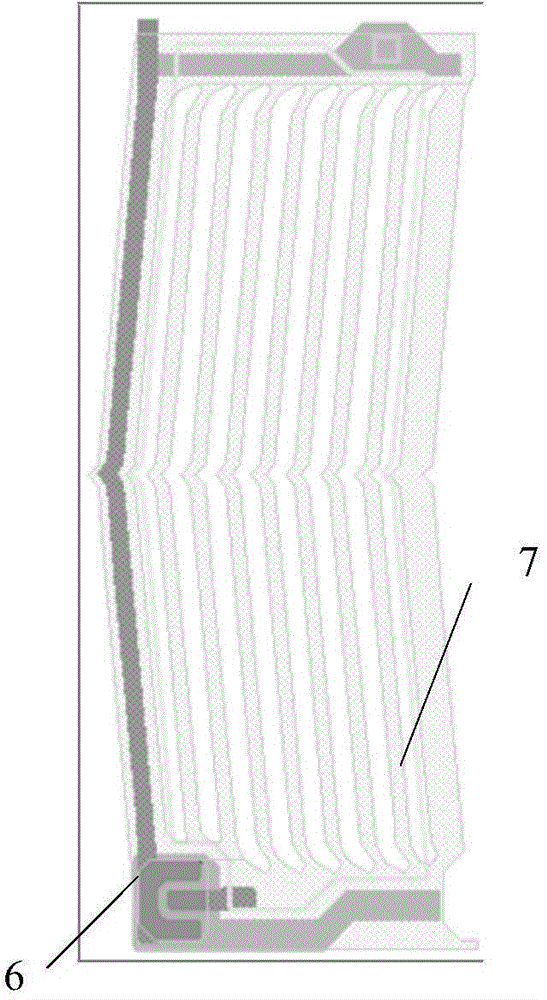

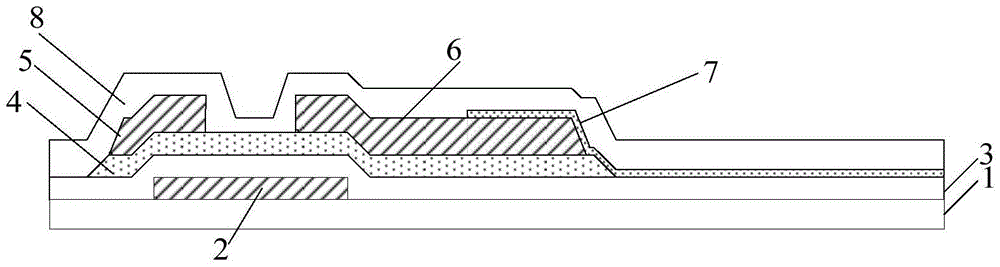

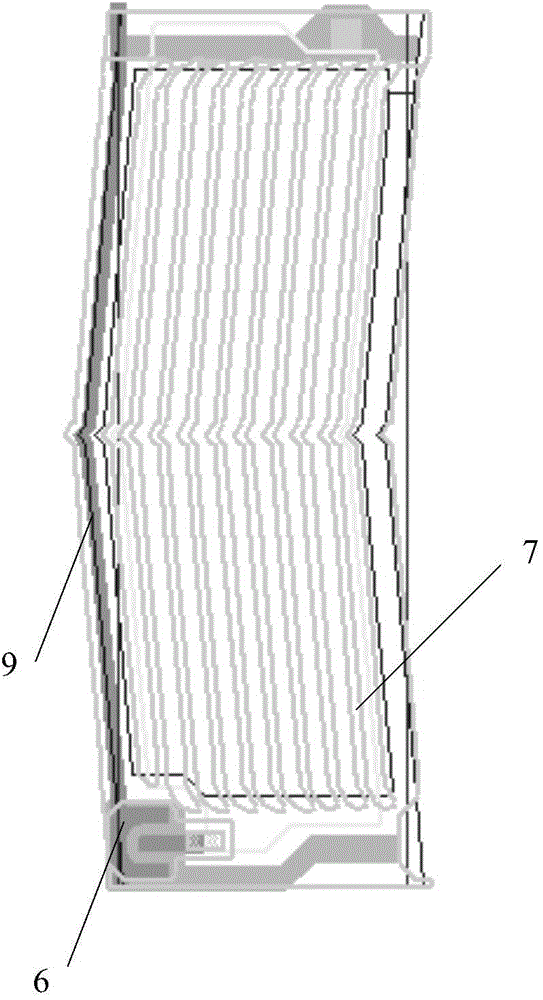

[0052] This embodiment provides an array substrate, including a plurality of pixel areas, each pixel area includes:

[0053] The pixel electrode and the drain electrode are arranged in the same layer and are independent of each other, and the pixel electrode and the drain electrode are connected through conductive components of different layers;

[0054] Wherein, an insulating layer is separated between the pixel electrode, the drain electrode, and the conductive member, and a position corresponding to the drain electrode of the insulating layer has a first via hole penetrating through the insulating layer, and the insulating layer is connected to the insulating layer. The position corresponding to the pixel electrode has a second via hole through the insulating layer, the drain electrode is connected to the conductive component through the first via hole, and the pixel electrode is connected to the conductive component through the second via hole. The above-mentioned conducti...

Embodiment 2

[0065] This embodiment provides a display device, including the above array substrate. The display device can be any product or component with a display function such as a liquid crystal panel, a liquid crystal TV, a liquid crystal display, a digital photo frame, a mobile phone, and a tablet computer.

Embodiment 3

[0067] This embodiment provides a method for manufacturing an array substrate, the array substrate includes a plurality of pixel regions, and the method includes:

[0068] In each pixel region, a pixel electrode and a drain electrode arranged in the same layer and independent of each other are formed, and a conductive member of a different layer is formed to connect the pixel electrode and the drain electrode;

[0069] Wherein, an insulating layer is separated between the pixel electrode, the drain electrode, and the conductive member, and a position corresponding to the drain electrode of the insulating layer has a first via hole penetrating through the insulating layer, and the insulating layer is connected to the insulating layer. The position corresponding to the pixel electrode has a second via hole through the insulating layer, the drain electrode is connected to the conductive component through the first via hole, and the pixel electrode is connected to the conductive co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com