A trapezoidal yoke permanent magnet vibration power generation device

A technology of vibration power generation and trapezoidal magnetic poles, applied in electromechanical devices, electrical components, etc., can solve the problems of not using the magnetic yoke, not suitable for vibration, waste of magnetic field, etc., to improve utilization rate, reduce volume, and improve utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

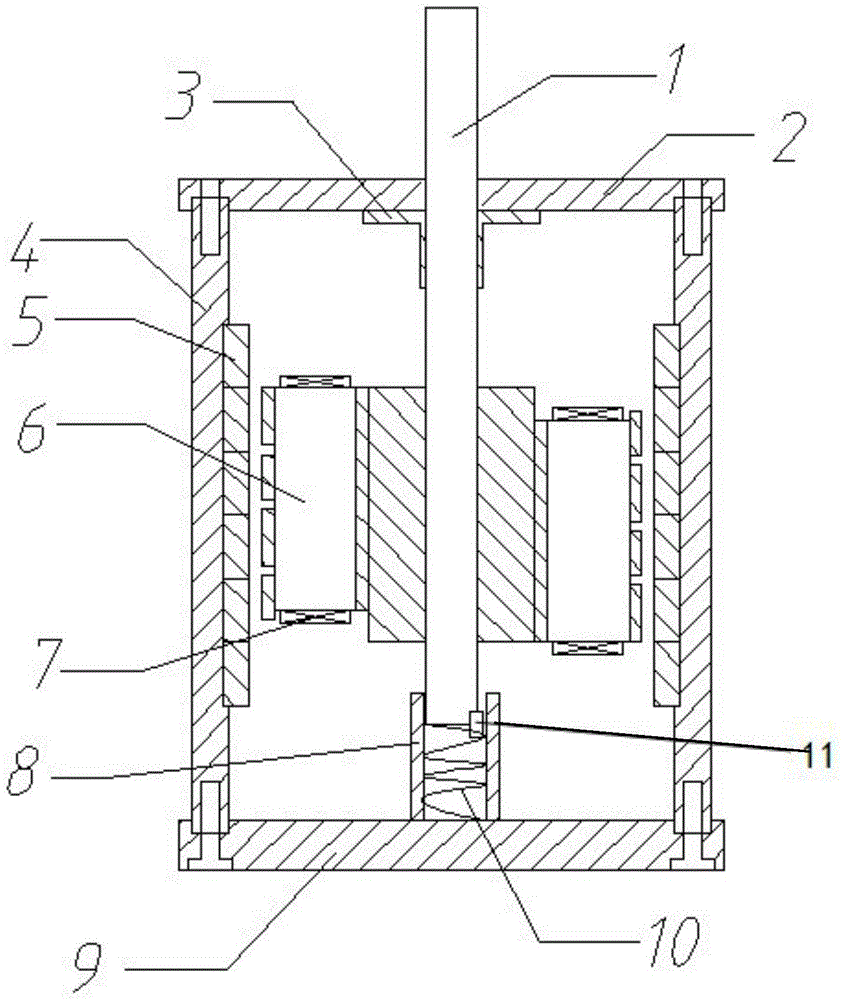

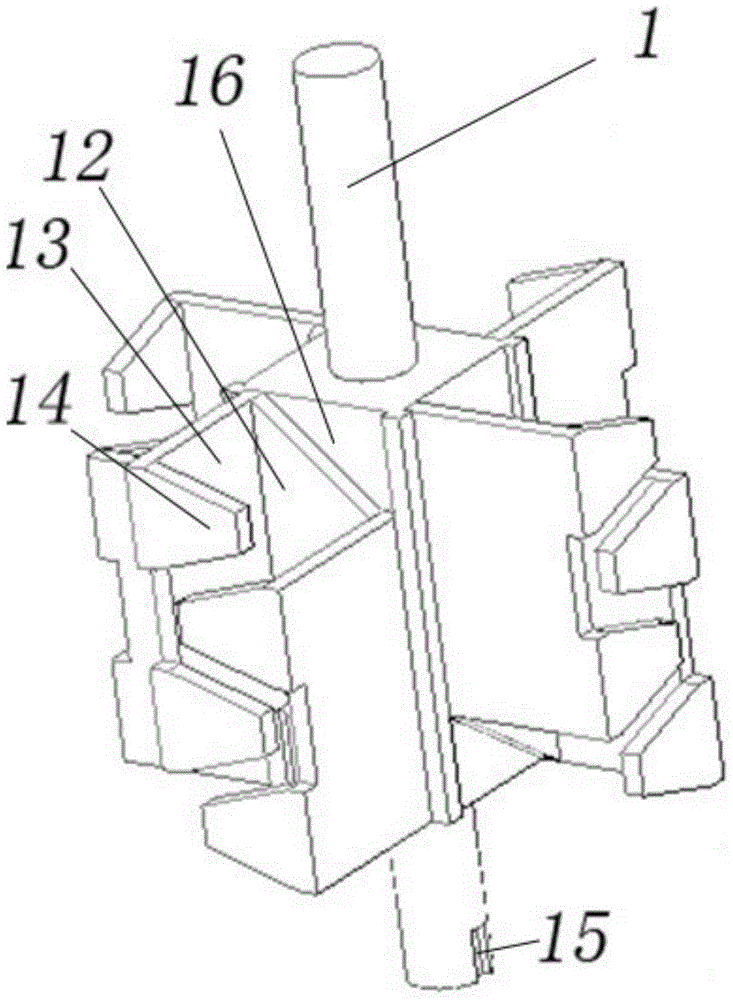

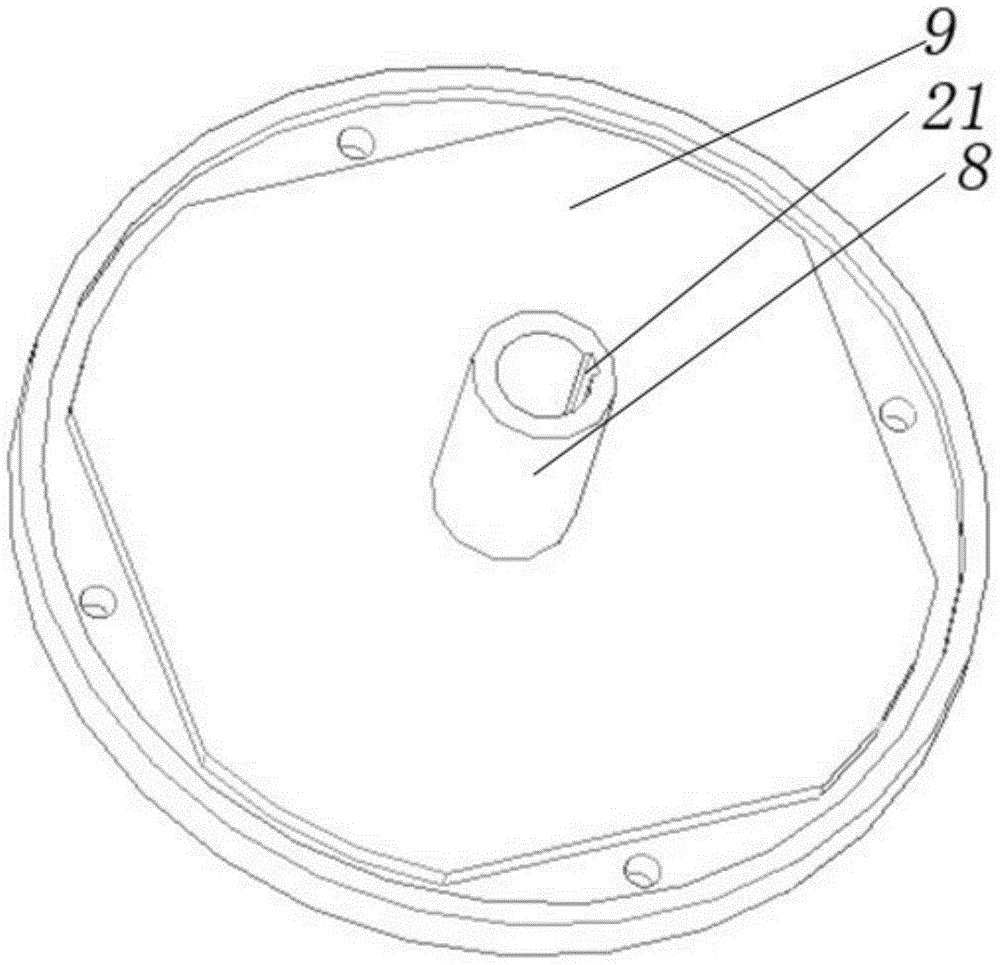

Embodiment 1

[0047] This embodiment adopts the above-mentioned connection method, the top cover 2 and the bottom cover 9 are both cylindrical plates with circular grooves on the edges, and the grooves of the top cover and the bottom cover are used to embed the cylindrical shell 4 in the middle. The six tetragonal permanent magnets 31-36 (each tetragonal permanent magnet is a neodymium iron boron permanent magnet (Nd2Fe14B, model N45)) on each table 37 inside the cylindrical shell 4 are closely attached together longitudinally, The characteristics are reversed, and there are four permanent magnet groups 5 symmetrically and evenly distributed along the housing. Vibration shaft 1 part: choose the aluminum alloy (non-magnetic material) whose middle part is a regular quadrangular prism body and the upper and lower parts are cylindrical as the vibration shaft 1 to avoid affecting the magnetic circuit. The total length of the vibrating shaft is 120mm, and the diameter at both ends is 8mm. The size...

Embodiment 2

[0052] The connection method of this embodiment is the same as that of Embodiment 1, the difference is that the top cover 2 and the bottom cover 9 are tightly connected with the outer shell 4 through a matching tenon-and-mortise joint structure. The power generating device can output a larger output voltage when the vibration frequency is 1-20 Hz and the vibration displacement peak value is 1-20 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com