Power-driven four-wheeler controller

An electric four-wheeled vehicle and controller technology, applied in electrical components, electrical equipment shells/cabinets/drawers, cooling/ventilation/heating renovation, etc., can solve the loss of controller function, power tube burnout failure, fast speed, etc problems, to achieve the effect of eliminating overheating and burnout, ensuring timeliness and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

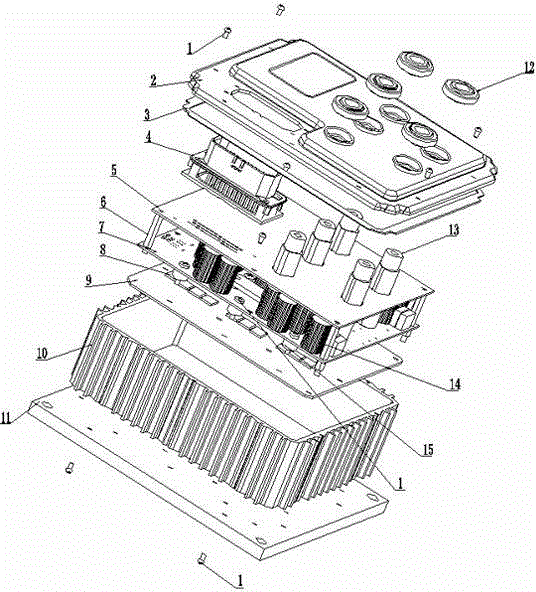

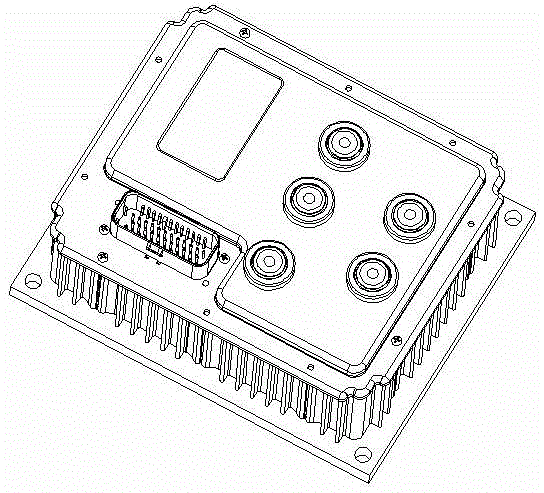

[0019] Such as figure 1 , figure 2 As shown, the present invention includes a bottom plate (11), a heat dissipation shell (10), a gasket (3), a plastic cover (2), a screw (1), a threaded support column I (6), a threaded support column Ⅱ (15), functional plug (4), large line terminal (13), capacitor (14), power tube (8). The middle is a hollow heat dissipation shell (10), the bottom plate (11) is a thick aluminum plate, the top is a plastic cover (2), and the interior of the hollow heat dissipation shell (10) is equipped with PCB board I (5), PCB board II (7) and an aluminum base plate (9), welded on the aluminum base plate (9) are fastened forty-eight power tubes (8) and ten threaded support columns II (15), threaded support columns II ( 15) Lock the aluminum base plate (9) on the bottom plate (11), and connect it to the PCB board II (7) at the same time; install the capacitor (14), the large wire terminal (13) and the PCB board I (5) Threaded support column I (6), one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com