Improved tobacco stalk cutting, separating and pre-loosening equipment for whole tobacco bale feeding

An improved cigarette package technology, which is applied in the fields of tobacco, tobacco processing, application, etc., can solve the problem that the accuracy of the cutting length of the cigarette stem cannot be guaranteed stably, it cannot fully meet the diversified production needs of users, and it cannot meet the needs of increasing production capacity and other problems, to achieve the effect of compact structure, simple structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

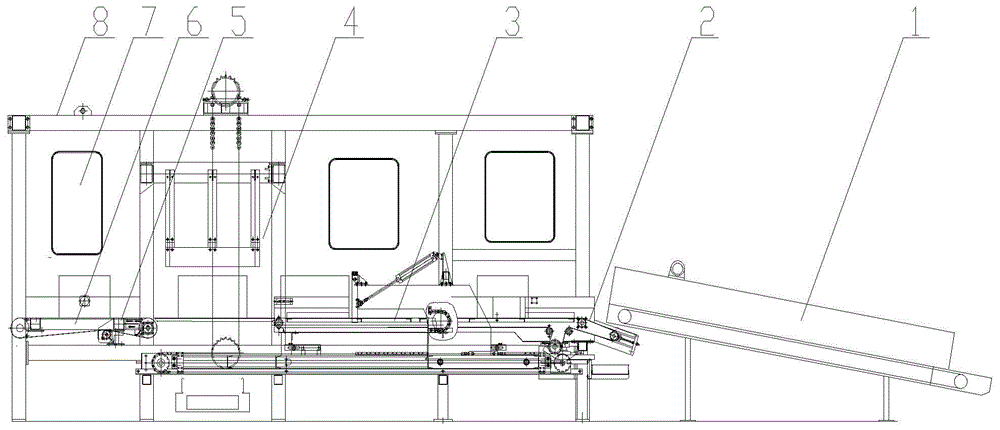

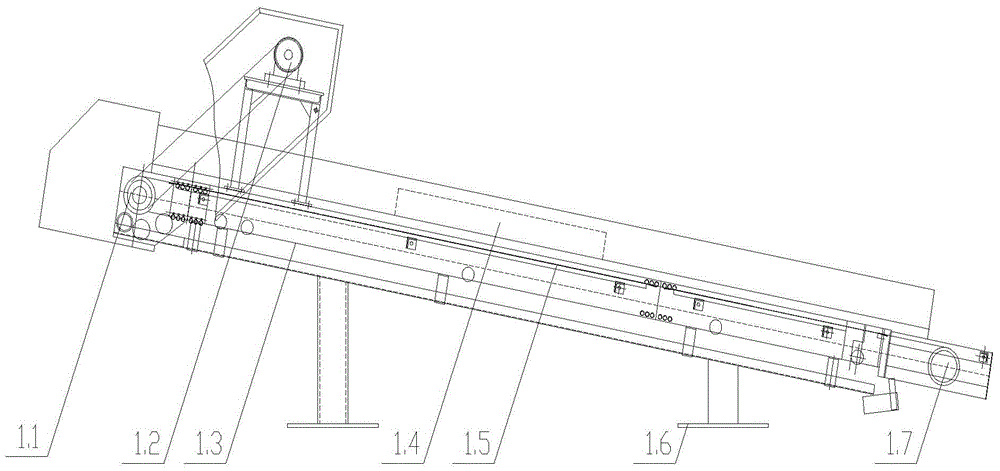

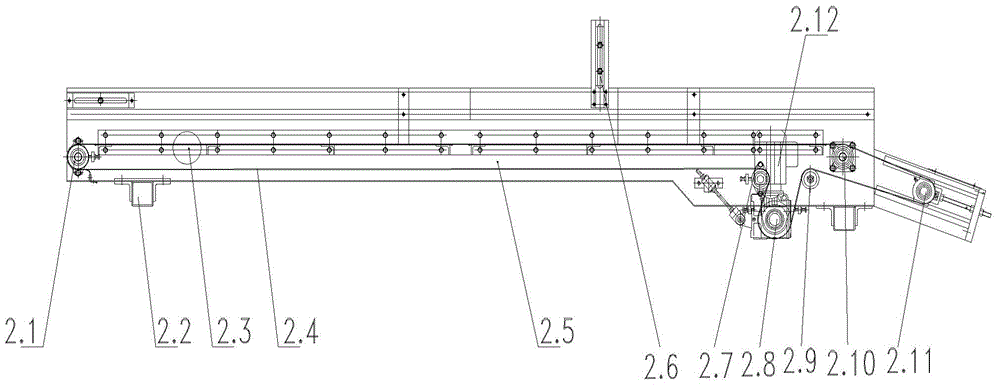

[0026] Such as figure 1 As shown in the figure, an improved tobacco stalk cutting and separating pre-loosening equipment for feeding whole packs of cigarettes includes a cache, a material guide belt conveyor 1, a feeding belt conveyor 2, an upper pushing device 3, a tobacco leaf stalk cutting and separating device 4, Tobacco leaf stalk clamping device 5 and complete machine frame 6, complete machine frame 6 is the foundation of complete machine, except buffer buffer, material guide belt conveyor 1, all devices are installed on the complete machine frame 6 in sequence, forming A whole, its two sides are closed with doors, and three plexiglass observation windows 7 are respectively equipped with, and the top of the plexiglass observation windows 7 is provided with a sealing cover 8, forming a closed space to prevent safety accidents. The pre-loosening equipment has the functions of feeding the whole pack of cigarettes in the loose leaf mode, cutting and separating the tobacco le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com