Application of Irradiation Treatment in Fermentation and Quality Improvement of Cigar Tobacco

A technology for cigars and cigar leaves, which is applied in the field of tobacco processing and achieves the effects of relieving excessive tobacco leaves, improving bitterness and enhancing aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The raw tobacco on the upper part of the cigar core is irradiated, the radiation dose is 9.5kGy, and the irradiation temperature is 37°C. The packaging container is made of oak box. When the irradiation reaches 1 / 2 of the predetermined dose, the wooden box is rotated 180° to continue the irradiation. After irradiation, store in the dark for 3 months under the conditions of ambient temperature 18° C. and relative humidity 65%.

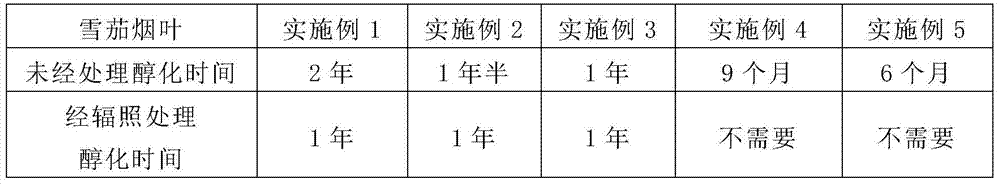

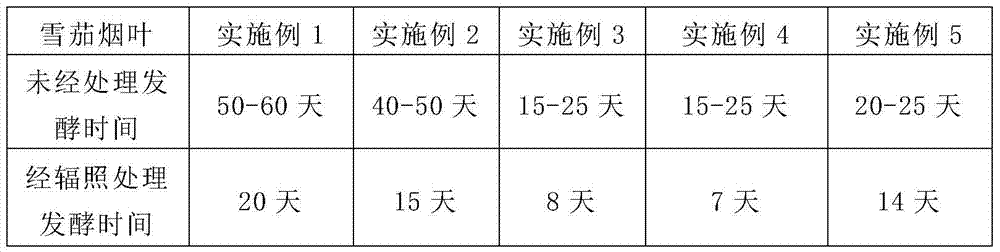

[0023] The upper part of the filler usually has a natural aging time of not less than 2 years. After the tobacco leaves are irradiated, the aging and fermentation time is greatly shortened, and the sensory quality reaches the quality of the tobacco leaves that have been naturally aged for more than two and a half years. After the treatment, the smoke style of the tobacco leaves does not change much, the degree of bitterness is obviously reduced, the richness of aroma is enhanced, and the miscellaneous gas, irritation and vigor are all reduced.

Embodiment 2

[0025] The raw tobacco in the middle part of the cigar core is irradiated, the radiation dose is 9kGy, and the irradiation temperature is 35°C. The packaging container is made of oak box. When the irradiation reaches 1 / 2 of the predetermined dose, the wooden box is rotated 180° to continue irradiation. After irradiation, store in the dark for 3 months at an ambient temperature of 22° C. and a relative humidity of 75%.

[0026] As the main source of the aroma of a cigar, the middle part of the filler tobacco must have a natural aging time of no less than one and a half years. After the tobacco leaves are irradiated, the aging and fermentation time is greatly shortened, and the sensory quality reaches the quality of the tobacco leaves that have been naturally aged for more than 2 years. After treatment, the smoke style of the tobacco leaves does not change much, the degree of bitterness is significantly reduced, the richness of aroma is significantly enhanced, and the miscellane...

Embodiment 3

[0028] The lower part of the cigar core is treated with radiation, the radiation dose is 8kGy, and the radiation temperature is 30°C. The packaging container is made of oak box. When the radiation reaches 1 / 2 of the predetermined dose, the wooden box is rotated 180° to continue the irradiation. After irradiation, store in the dark for 2 months under the conditions of ambient temperature 20°C and relative humidity 70%.

[0029] The lower part of the filler tobacco is mainly used as a cigar filler, and its natural aging time should not be less than one year. The sensory quality of the tobacco leaves was not significantly changed after irradiation treatment, but the fermentation period was greatly shortened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com