Diisostearyl malate decolorizing agent and deep decolorizing method

A technology of diisostearyl malate and depigmenting agent, which is applied in the directions of pharmaceutical formulations, skin care preparations, cosmetics, etc., can solve the problems such as the inability to reduce the chromaticity of diisostearyl malate, and achieve lasting freshness Effect of fragrance, simple preparation method and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

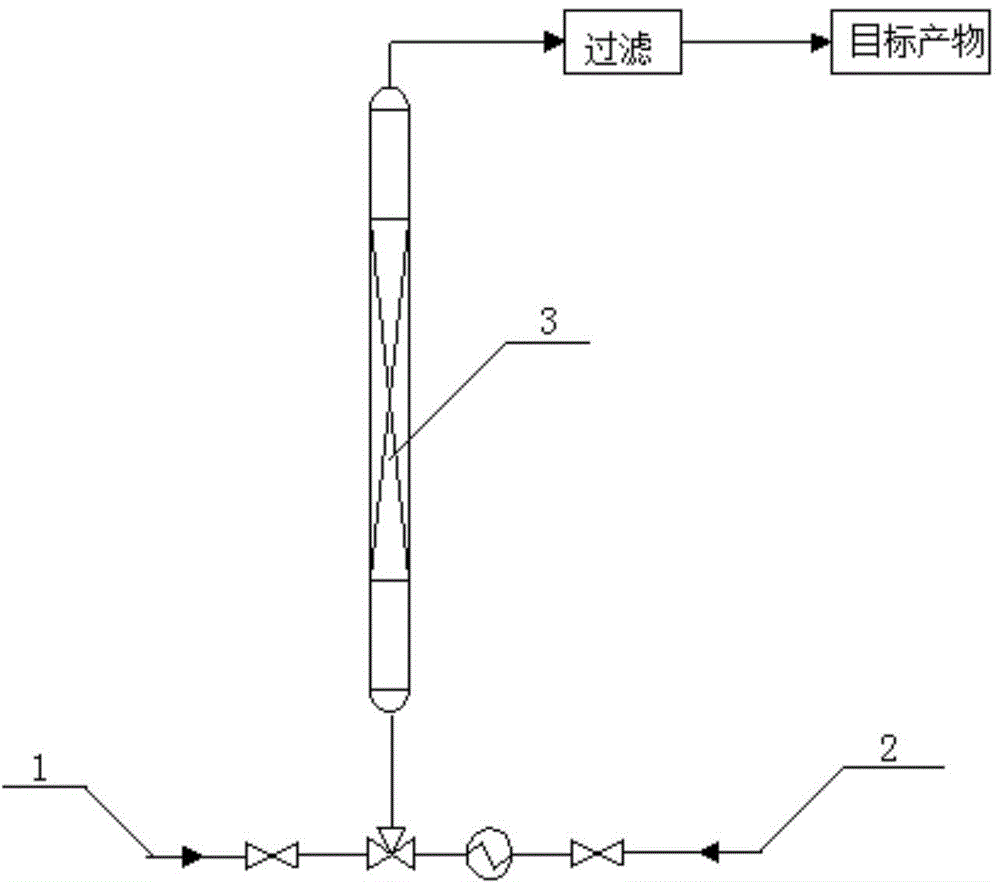

Image

Examples

Embodiment 1

[0019] The decolorizing agent 3 that the present invention selects is loaded with ZrO 2 and ZnO activated carbon, where ZrO 2 and the loadings of ZnO are expressed by weight percent relative to activated carbon, ZrO 2 The loading amount of ZnO is 4%, and the loading amount of ZnO is 1%.

[0020] The depth decolorization method of diisostearyl malate comprises the following steps:

[0021] Prepare decolorizing agent 3 by dipping method;

[0022] Pretreatment of decolorizing agent: put 50g of decolorizing agent into a fixed bed heated by electric charge, fill the top and bottom of decolorizing agent 3 with quartz sand, heat the bed layer containing decolorizing agent 3 to 350°C, and at the same time continuously feed hydrogen gas 1 to treat 4 Hour.

[0023] Decolorization treatment: cool down the bed layer containing the decolorizing agent 3 and maintain it at 100°C, while heating the diisostearyl malate 2 to 100°C, stop feeding the hydrogen gas 1, and heat the heated diisos...

Embodiment 2

[0026] The decolorizing agent 3 that the present invention selects is loaded with ZrO 2 and ZnO activated carbon, where ZrO 2 and the loadings of ZnO are expressed by weight percent relative to activated carbon, ZrO 2 The loading amount of ZnO is 1%, and the loading amount of ZnO is 4%.

[0027] The depth decolorization method of diisostearyl malate comprises the following steps:

[0028] Prepare decolorizing agent 3 by dipping method;

[0029] Pretreatment of decolorizing agent: put 50g of decolorizing agent 3 into a fixed bed heated by electric charge, fill the top and bottom of decolorizing agent 3 with quartz sand, heat the bed layer containing decolorizing agent 3 to 380°C, and simultaneously pass hydrogen gas 1 continuously for treatment 4 hours.

[0030] Decolorization treatment: cool down the bed layer containing the decolorizing agent 3 and maintain it at 100°C, heat diisostearyl malate 2 to 120°C at the same time, stop feeding hydrogen 1, and heat the heated diis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com