A long rod spray gun spraying bracket

A spray gun and long rod technology, which is applied to coatings, spray devices, and devices for coating liquid on surfaces, etc., can solve problems such as poor spray effect and low spray efficiency, and achieve improved quality, easier processing, and improved spray stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

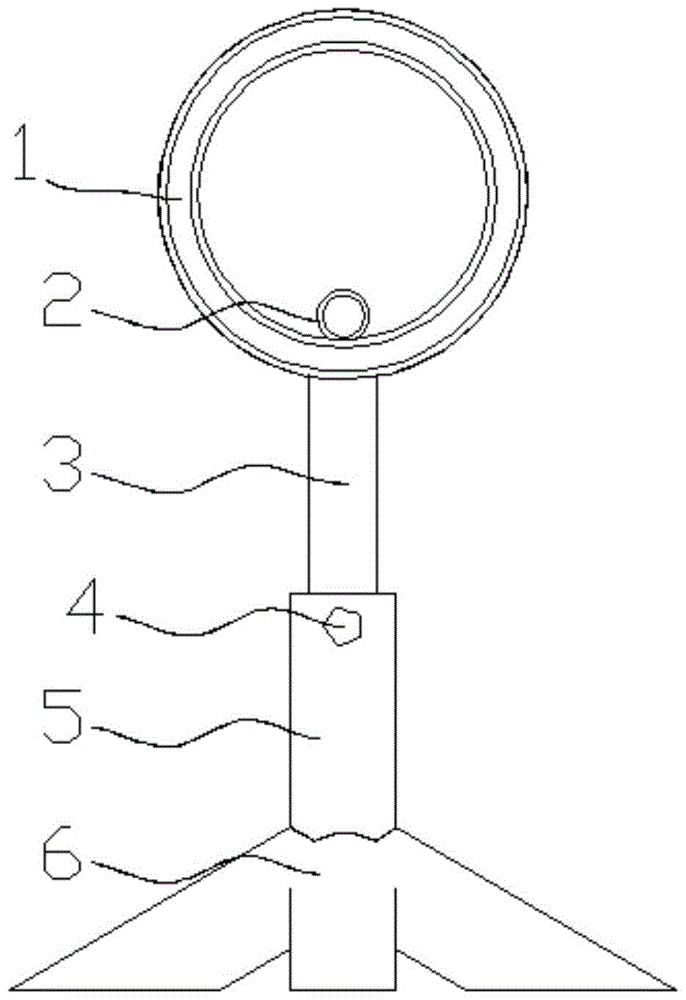

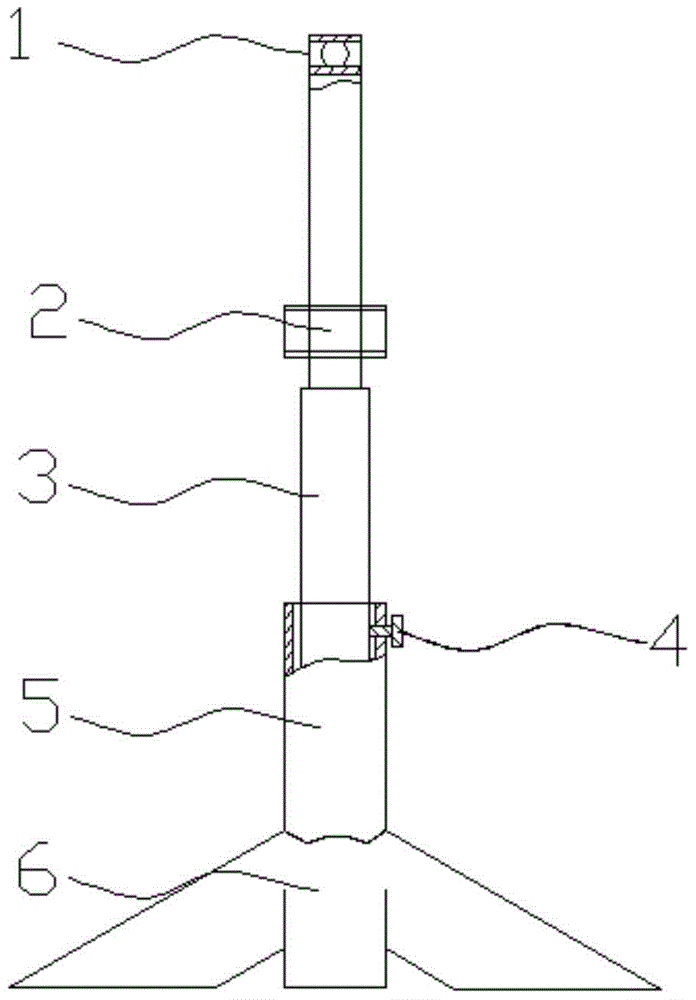

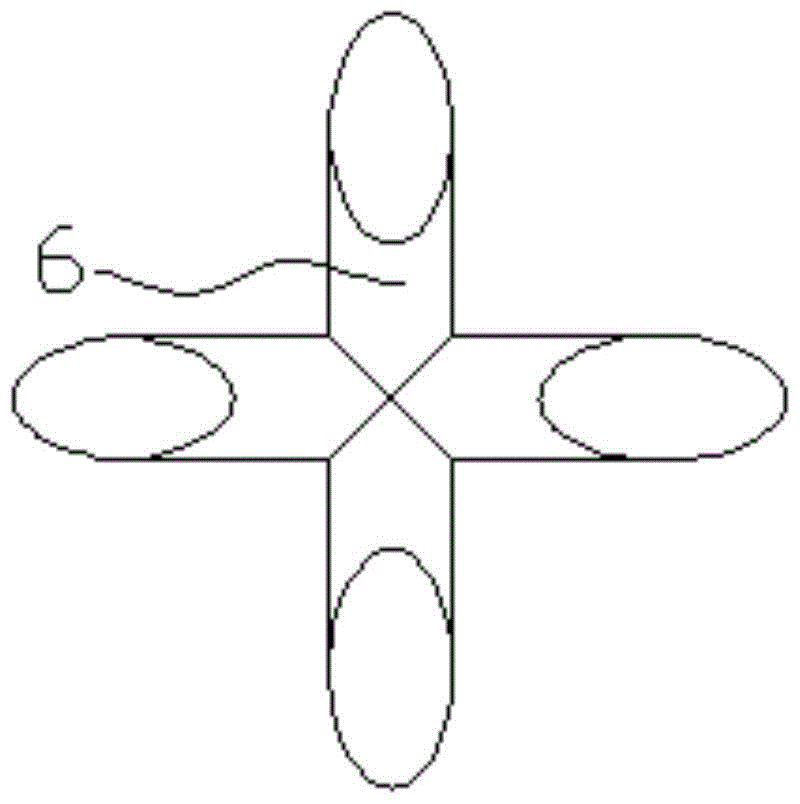

[0026] Such as figure 1 , figure 2 with image 3 As shown, the spraying support of the long rod spray gun of this embodiment includes a bearing 1, a barrel sleeve 2, a support rod 3, and a base 6. The bearing 1 is fixed on the upper end of the support rod 3. Specifically, the upper end of the support rod 3 is cut outside For the outer ring of the bearing 1, the outer ring of the bearing 1 is fixed to the upper end of the strut 3 by welding. The barrel sleeve 2 is fixed on the inner ring of the bearing 1, and the central axis of the barrel sleeve 2 and the central axis of the bearing 1 are parallel to each other. Specifically, the barrel sleeve 2 is inscribed in the inner ring of the bearing 1, and the barrel sleeve 2 It is fixed to the inner ring of the bearing 1 by welding, and the gun barrel 2 and the bearing 1 constitute the rotating mechanism of the spraying bracket of the long-barrel spray gun of this embodiment. The upper end of the base 6 is provided with a connecting ...

Embodiment 2

[0052] The spraying bracket of the long rod spray gun of this embodiment has the same basic structure as that of the embodiment 1, and the difference is that the bearing 1 is a deep groove ball bearing, and the inner ring of the bearing 1 has a diameter of 150 mm.

[0053] The spraying process for the inner wall of the metal pipe of this embodiment includes the following steps:

[0054] Step 1. Inner wall substrate treatment:

[0055] Prepare the metal pipe to be sprayed, and the inner diameter of the metal pipe is greater than the diameter of the circular atomization surface of the long rod spray gun, and the inner wall of the metal pipe is sequentially subjected to four operations: sandblasting and rust removal, angle grinder polishing, sandpaper polishing and inner wall preheating;

[0056] Step 2. Debugging of spraying equipment:

[0057] Assemble the air compressor, pressure paint tank and long rod spray gun, and adjust the pressure of the pressure paint tank to 0.4MPa;

[0058] Ste...

Embodiment 3

[0065] The spraying process for the inner wall of the metal pipe of this embodiment includes the following steps:

[0066] Step 1. Inner wall substrate treatment:

[0067] Prepare the metal pipe to be sprayed, and the inner diameter of the metal pipe is less than or equal to the diameter of the circular atomization surface of the long rod spray gun, and the inner wall of the metal pipe is sequentially subjected to four operations: sandblasting and rust removal, angle grinder polishing, sandpaper polishing and inner wall preheating ;

[0068] Step 2. Debugging of spraying equipment:

[0069] Assemble the air compressor, pressure paint tank and long rod spray gun, and adjust the pressure of the pressure paint tank to 0.4MPa;

[0070] Step 3. Long rod spray gun positioning:

[0071] Prepare the spraying bracket of the long-barrel spray gun, insert the barrel of the long-barrel spray gun into the barrel sleeve 2, adjust the depth of the lower end of the support rod 3 into the connecting sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com