Powder leaking device

A technology of powder leakage and crushing chamber, which is applied to the device and coating of the surface coating liquid, which can solve the problems of interruption of process flow, uneven flow of powder spraying, affecting the quality of powder spraying, etc., so as to avoid the blockage of the discharge port , to ensure the process requirements, to ensure the effect of pulverization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

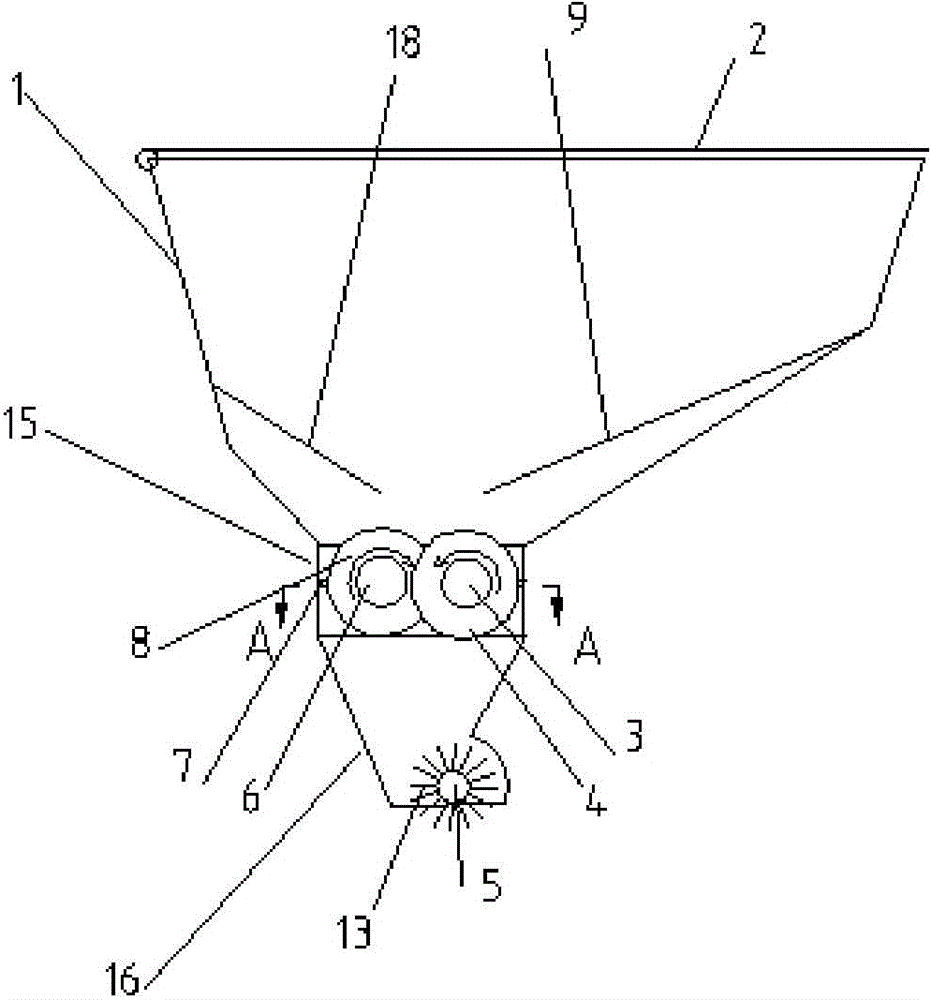

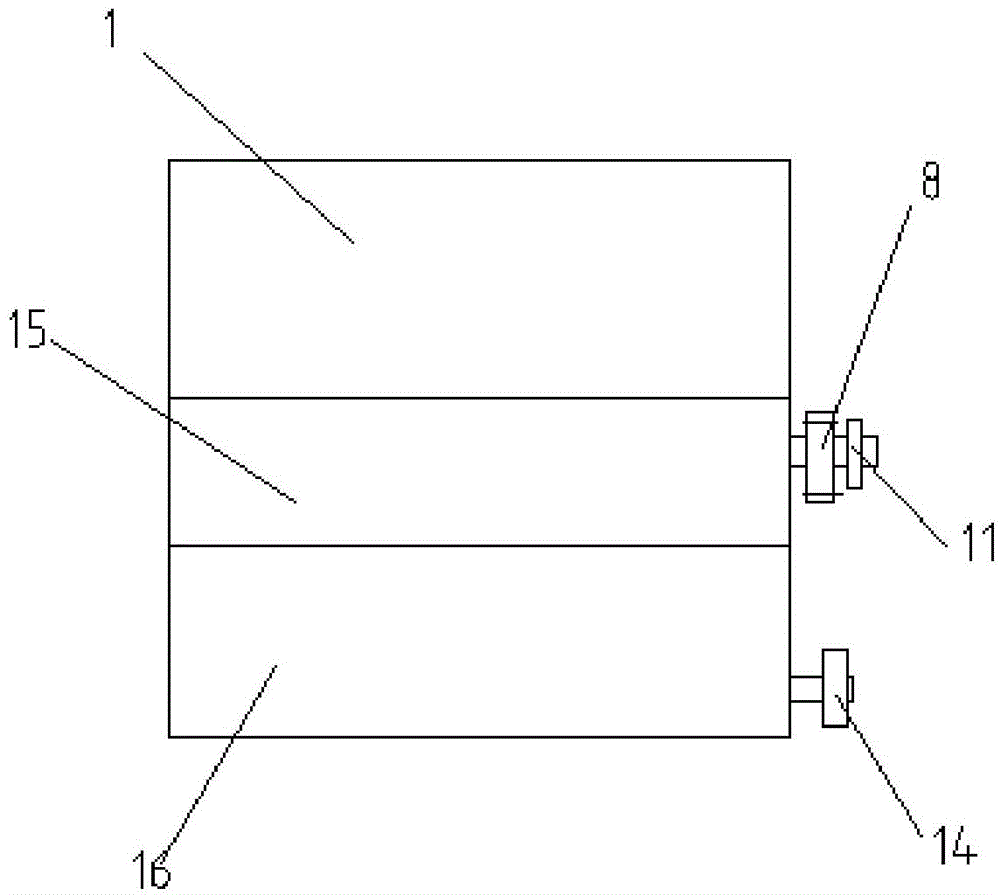

[0019] The present invention is described according to accompanying drawing now, as figure 1 , figure 2 , image 3 As shown, a powder leaking device includes a storage chamber 1, a crushing chamber 15 and a discharge chamber 16 connected sequentially from top to bottom;

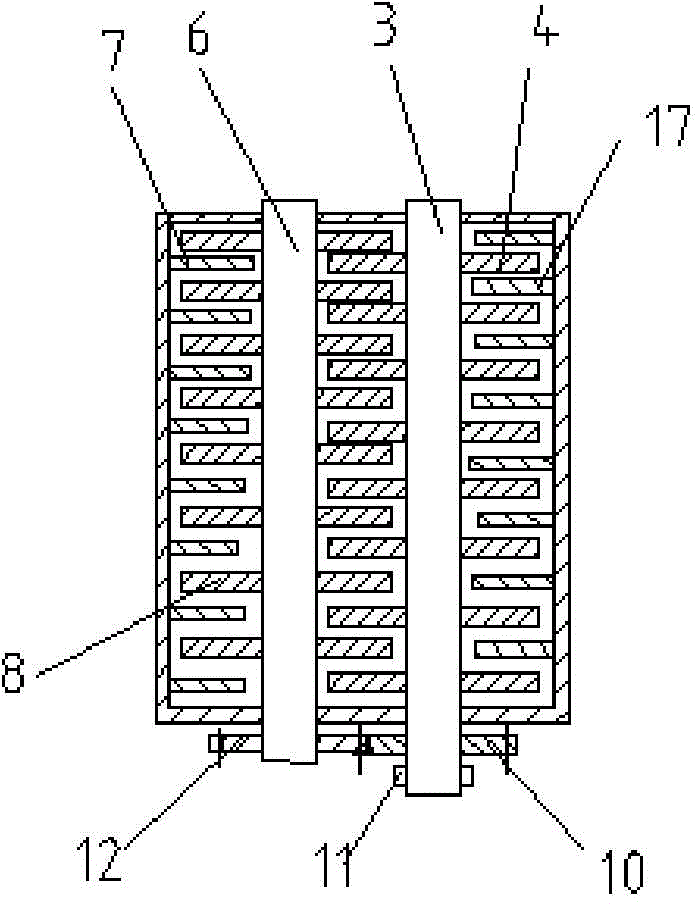

[0020] The crushing chamber 15 is provided with a driving shaft 3 and a driven shaft 6. The driving shaft 3 is arranged horizontally. Both ends of the driving shaft 3 pass through the crushing chamber 15. One end of the driving shaft 3 is connected with a first gear 10 , and the end is connected with the first sprocket 11, the first gear 10 and the first sprocket 11 are located outside the crushing chamber 15, and the part of the drive shaft 3 located in the crushing chamber 15 is evenly distributed with a plurality of first A crushing disc 4, the first crushing disc 4 is perpendicular to the axis of the driving shaft 3; the driven shaft 6 is parallel to the driving shaft 3, and both ends of the driven sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com