Thallus sample crushing mechanism

A crushing mechanism and sample technology, applied in grain processing and other directions, can solve the problems of reduction, loss of biological activity of downstream proteins, and reduction of crushing efficiency of high-pressure homogenizers, so as to ensure crushing efficiency, ensure crushing efficiency and biological activity, and ensure The effect of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

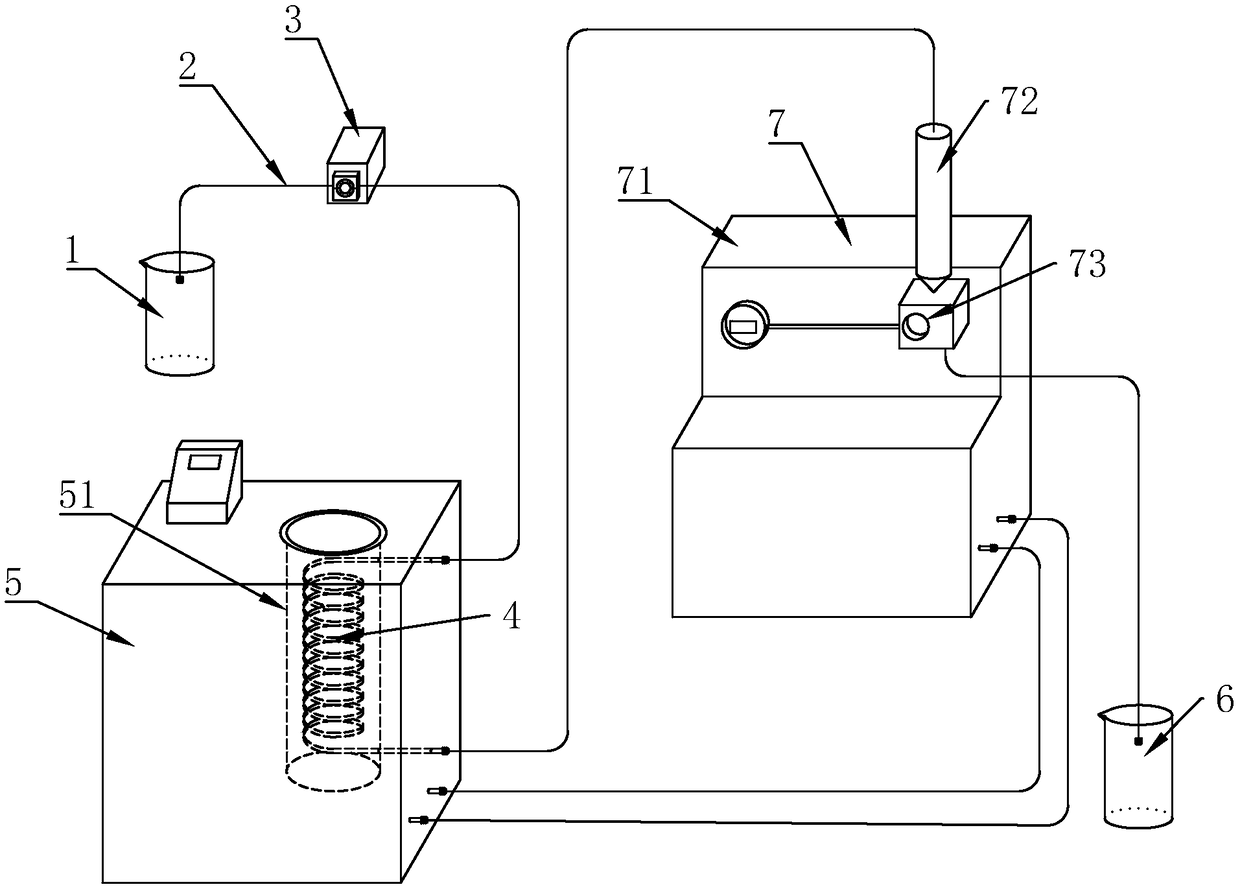

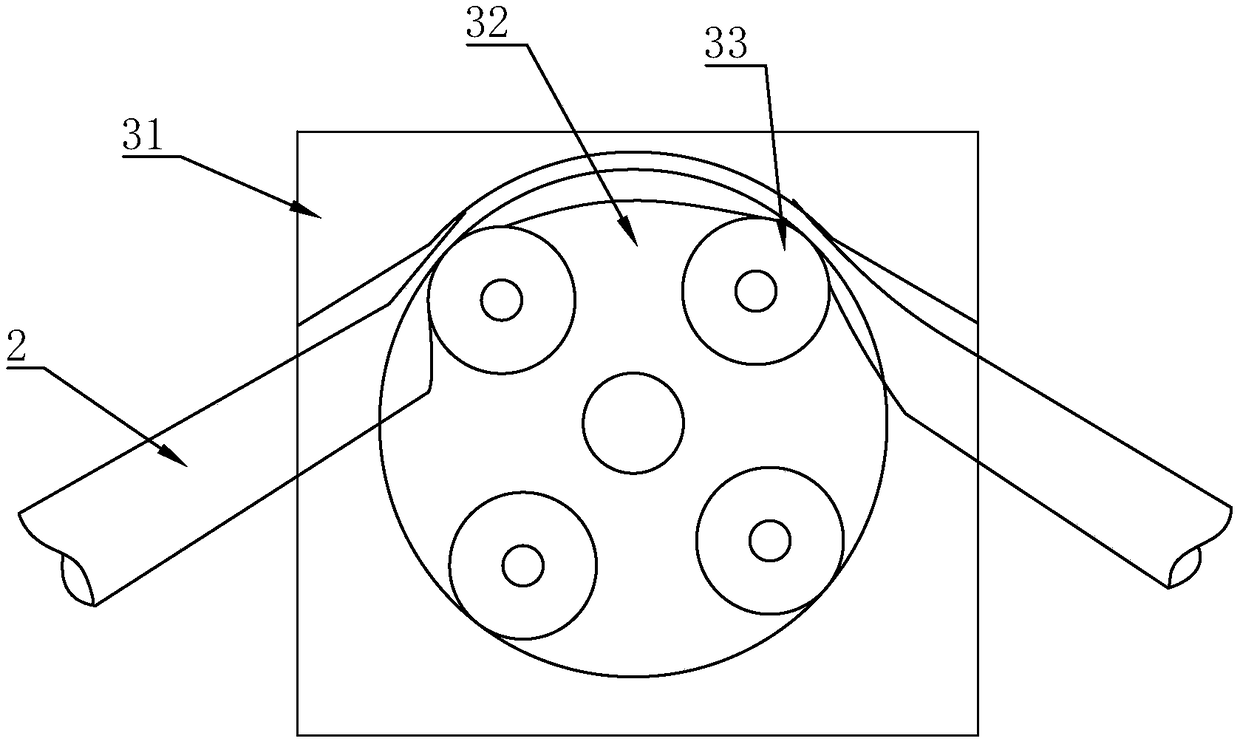

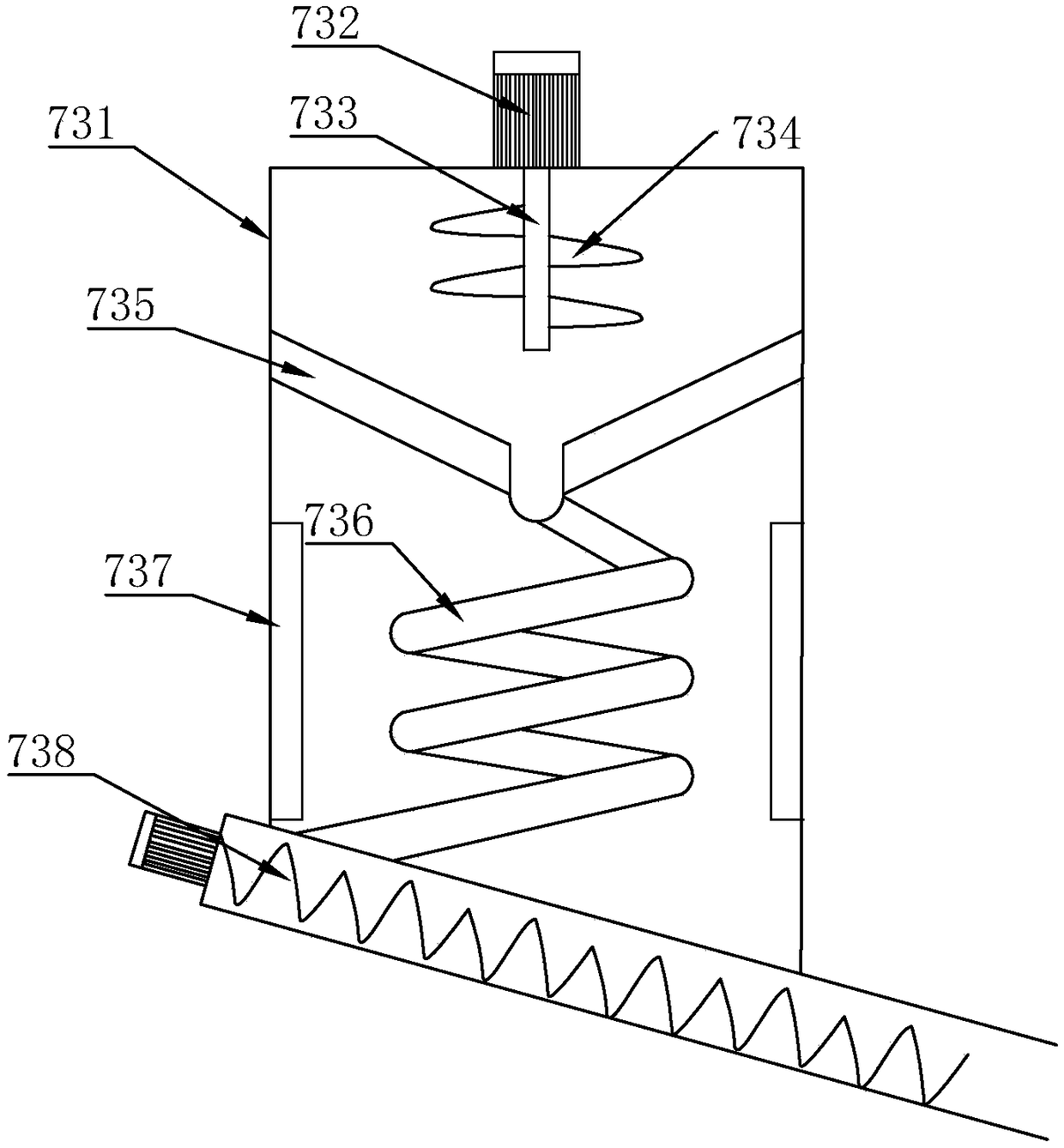

[0017] Such as Figure 1-Figure 2 As shown, a bacterium sample crushing mechanism of the present invention comprises a sampling cup, a peristaltic pump, a cooling cycle machine, a high-pressure homogenizer and a sample collection cup. The cooling cycle machine is provided with a cold water tank, and a sample tube is arranged in the cold water tank. The high-pressure homogenizer includes a body, which is equipped with a sampling tank and a crushing device. The sampling cup, peristaltic pump, sample tube, sampling tank, crushing device, and sampling cup are connected in sequence. Liquid channel, the outside of the crushing device is provided with a second cold liquid channel, the liquid outlet of the first cold liquid channel is connected to the liquid inlet of the second cold liquid channel, and the liquid inlet of the first cold liquid channel is connected to the second cold liquid channel. The outlet connection of the channel.

[0018] The sample tube has a spiral structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com