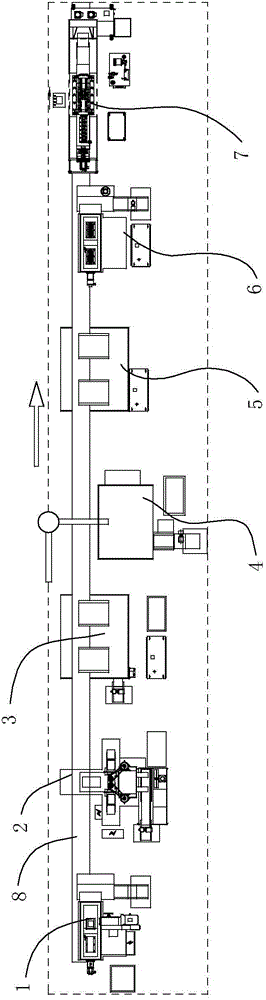

Automatic production technology and production line for tile covers

An automatic production and production line technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of cumbersome manual joint production efficiency and pass rate, achieve reasonable processing sequence arrangement, improve processing efficiency and processing accuracy, and process quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

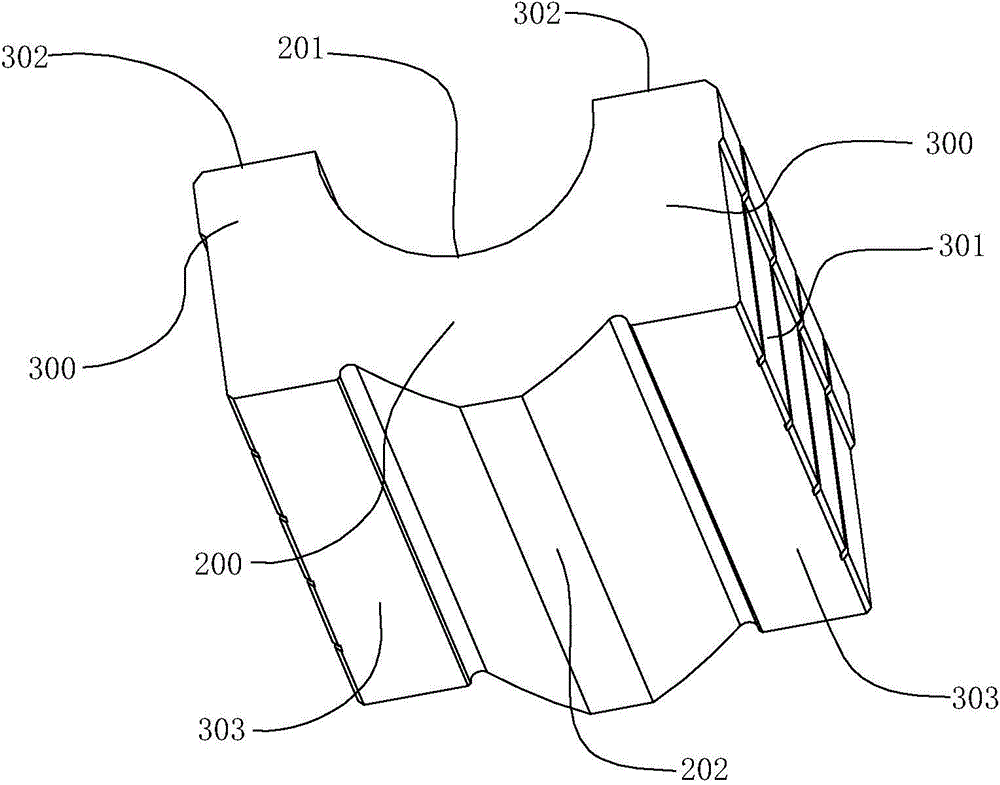

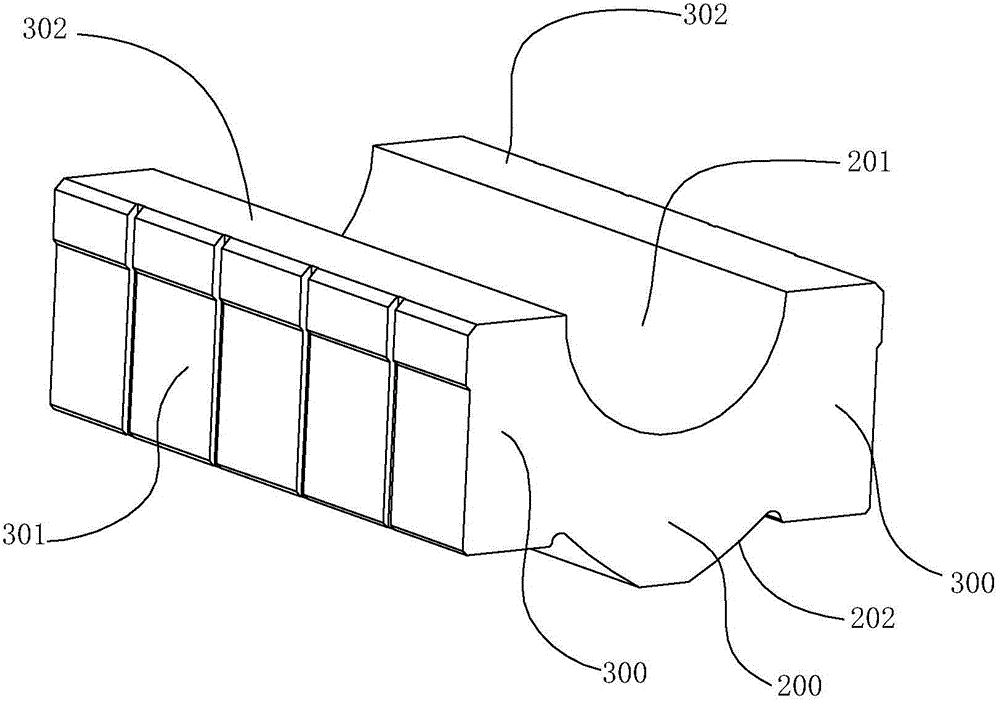

[0027] like Figure 2a , 2b , shown in 3a, 3b, Figure 2a , 2b It is a schematic diagram of the tile cover blank to be processed, and the tile cover blank is a plurality of tile cover blanks connected in sequence, Figure 3a , 3b It is a schematic diagram of the tile cover 100 after processing. The tile cover 100 includes an arc portion 200 and end portions 300 located at both ends of the arc portion 200. The arc portion 200 includes a concave surface 201 and a convex table surface 202 opposite to the concave surface. The end portions 300 include The outer side surface 301 located on the outer side, the joint surface 302 located on the side of the concave surface 201, and the shoulder surface 303 located on the side of the convex table surface 202, the shoulder surface 303 and the joint surface 302 are parallel to each other, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com