Oil guiding thermal cycle hot-press machine

A heat press and heat cycle technology, applied in veneer presses, plywood presses, wood processing appliances, etc., can solve the problems of slow heating and uneven heat distribution, and achieve uniform temperature distribution, simple structure and easy effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

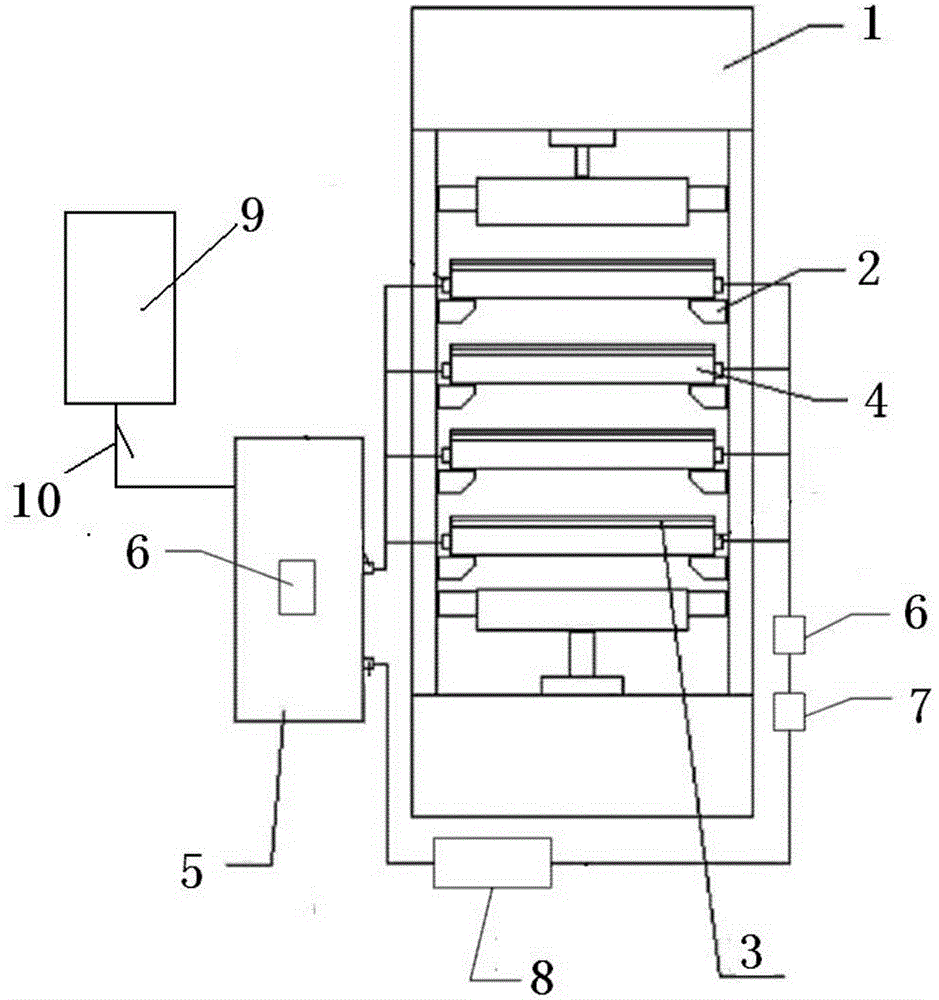

[0014] figure 1 Shown is an embodiment of an oil-conducting thermal cycle heat press machine of the present invention, the frame 1 of the heat press machine is sequentially installed with multi-layer brackets 2 that can move up and down along it, and each layer of bracket 2 Supporting plates 3 are respectively fixed on the top, and the supporting plates 3 on each layer of brackets 2 are respectively provided with cavities 4, and the two ends of the supporting plates on each layer of brackets 2 are respectively provided with oil inlets and outlets. One side of the hot press is provided with an oil heater 5, and the oil heater 5 is respectively provided with inlet and outlet ports communicating with the cavity, and the inlet and outlet ports at both ends of the supporting plate on each layer of bracket 2 The oil ports are respectively connected to the oil inlet and outlet ports of the oil heater 5 through pipelines. A temperature detector 6 is also arranged on the oil heater 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com