Double-winding-drum transmission device of motor-driven winch

A motorized winch and transmission technology, applied in transmission, winch, mechanical equipment, etc., can solve the problems of small traction force, narrow speed adjustment range, prone to running and grinding, etc., to achieve balanced torque transmission and ensure braking. Performance, the effect of not easy to partial load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

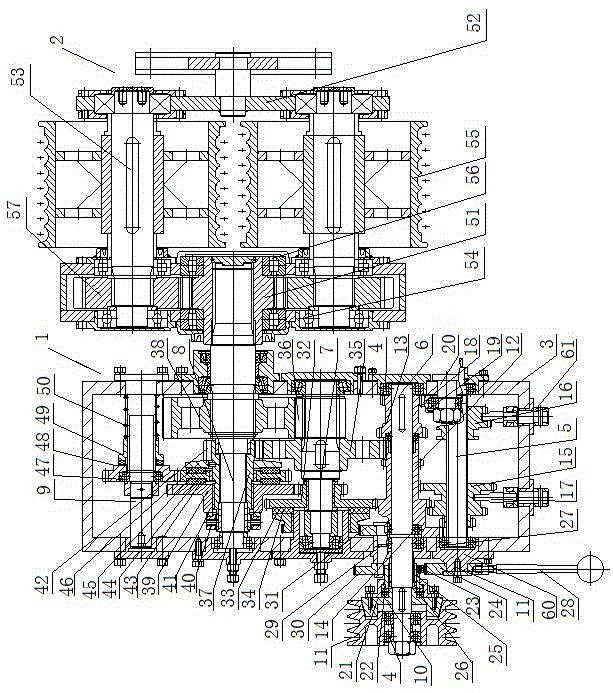

[0033] Such as figure 1 As shown, the present invention comprises a gear box 1 and a double drum winding reel 2 .

[0034] The reduction box 1 includes a housing 3, and the shift shaft 5 parallel to each other, the first input shaft 6, the intermediate transmission shaft 7 and the output shaft 8 are respectively installed in the housing 3 through the first bearing 4, and the shafts fixed in the housing 3 Brake shaft 9, gear shift shaft 5, first input shaft 6, intermediate transmission shaft 7 and housing 3 at both ends of output shaft 8 are all equipped with bearing end caps 60.

[0035] The input end of the first input shaft 6 protrudes outwards from the housing 1, the input end of the first input shaft 6 is provided with a clutch 10 and a transmission pulley 11, and the first input shaft 6 in the housing 1 is equipped with a variable speed power output triple Gear 12 and reversing dual gear 13, variable speed power output triple gear 12 and clutch 10 are installed on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com