Method for producing general cement without introducing polluting chromium

A production method and element technology, applied in the field of building materials production, can solve problems such as chromium element pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0013] When implementing the present invention, the chromium element-containing metal liner of the ball mill used in the general cement production process is replaced with a chromium-free industrial ceramic liner, and at the same time, the chromium-containing alloy grinding body is replaced with a ceramic material grinding body. The specific grading scheme of grinding bodies determined according to different sizes, specifications and shapes should be determined by those skilled in the art according to the actual situation of the specific grinding machine, which is not involved in the present invention. The ball mill includes a raw material ball mill, an ore powder ball mill and a cement grinding ball mill.

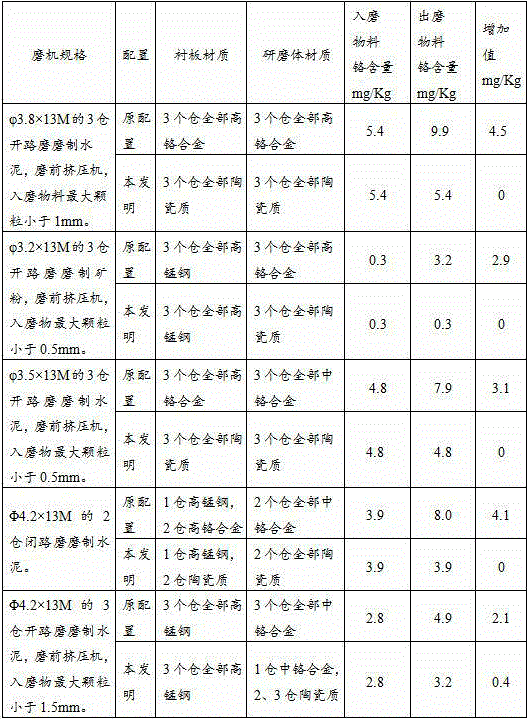

[0014] The scheme of the present invention and the comparison results before and after effects are shown in Table 1.

[0015] Table 1

[0016]

[0017] 1. Quality index of high chromium ball:

[0018] The chromium content ≥ 10.0% and the carbon content between 1.80%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com