A kind of early-strength foam cement slurry for well cementing

A technology of cement slurry and foam, which is applied in applications, household appliances, and other household appliances, etc., can solve the problems of slow development of foam cement strength, and achieve the effects of ensuring uniformity and stability, fast development of low-temperature strength, and short transition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

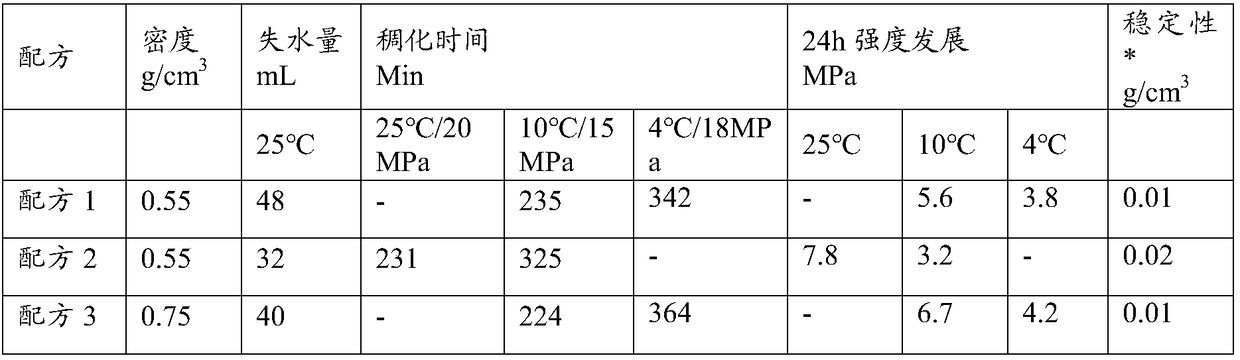

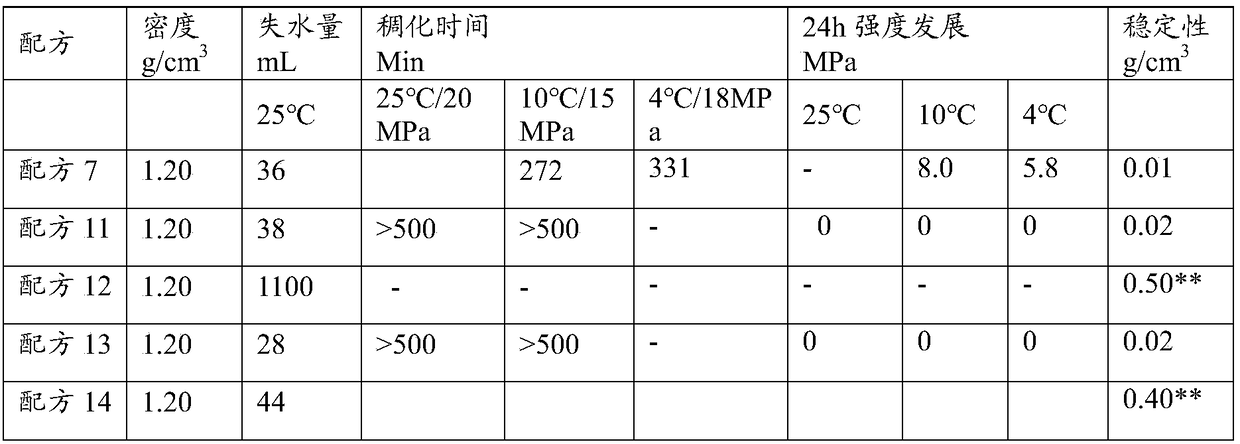

[0027] The early-strength foam cement slurry formula for well cementing provided by the embodiments of the present invention is as follows:

[0028] Formula 1: 100 parts of sulfoaluminate cement, 6 parts of foaming agent A, 6 parts of foaming agent B, 7 parts of foam stabilizer, 3 parts of fluid loss reducer, 1 part of retarder, and 31 parts of water.

[0029] Formula 2: 100 parts of sulfoaluminate cement, 6 parts of foaming agent A, 6 parts of foaming agent B, 7 parts of foam stabilizer, 4 parts of fluid loss reducer, 2.5 parts of retarder, and 30 parts of water.

[0030] Formula 3: 100 parts of sulfoaluminate cement, 5 parts of foaming agent A, 5 parts of foaming agent B, 5.4 parts of foam stabilizer, 4 parts of fluid loss reducer, 1.2 parts of retarder, and 33 parts of water.

[0031] Formula 4: 100 parts of sulfoaluminate cement, 5 parts of foaming agent A, 5 parts of foaming agent B, 5.4 parts of foam stabilizer, 5 parts of fluid loss reducer, 3.0 parts of retarder, and 3...

example 2

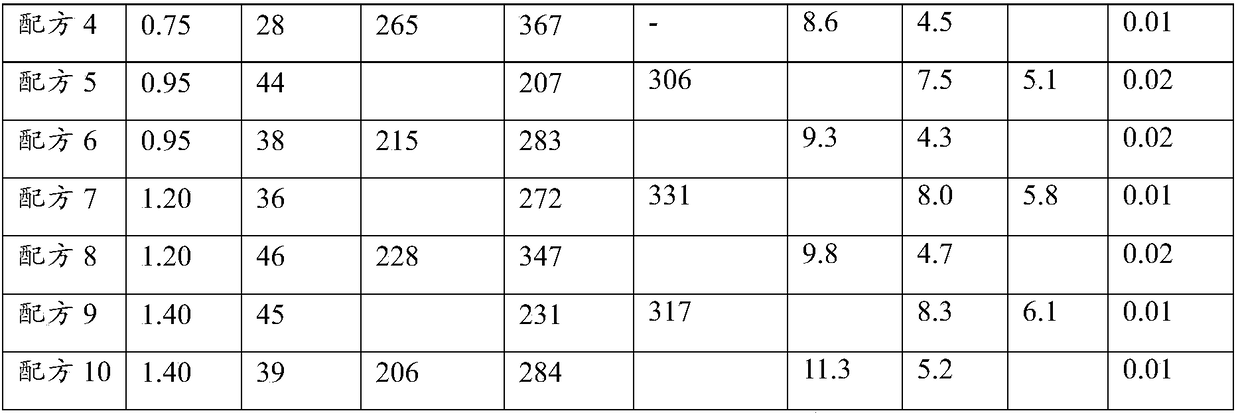

[0044] Compared with the formula in patent CN103525387 and the article "Ultra-low density foam cement slurry suitable for cementing in Changqing Oilfield"

[0045] Adopt cement slurry formula and admixture in CN103525387:

[0046] Cement slurry formula 11: 100 parts of oil well cement, 1.0 parts of foaming agent I, 1.0 parts of foaming agent II, 1.3 parts of foam stabilizer, 1.45 parts of fluid loss reducer, 0.2 parts of dispersant, 0.6 parts of retarder, 52 parts of water share.

[0047] Cement slurry formula 12: 100 parts of sulfoaluminate cement, 1.0 parts of foaming agent I, 1.0 parts of foaming agent II, 1.3 parts of foam stabilizer, 1.45 parts of fluid loss reducer, 0.2 parts of dispersant, and 0.6 parts of retarder , 52 parts of water.

[0048] The following cement slurry was prepared using the admixtures described in the article "Ultra-low density foam cement slurry for Changqing Oilfield cementing":

[0049] Cement slurry formula 13: 100 parts of oil well cement, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com