Method for solving exceeding standard problem of hexavalent chromium from natural leather

A technology of natural leather and hexavalent chromium, applied in leather surface treatment, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve high cost, fatliquoring Less additives, impact on the quality of leather, etc., to achieve the effect of reasonable cost, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

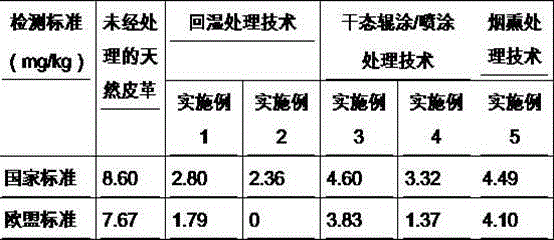

Embodiment 1

[0021] A method for solving the problem of hexavalent chromium exceeding the standard in natural leather is a rewetting treatment technology, comprising the following steps:

[0022] Step 1. Take a certain amount of natural leather with hexavalent chromium exceeding the standard, and sample and detect the moisture and volatile content of the natural leather according to the industry standard (QB / T 2717-2005 Detection of Moisture and Volatile Matter in Leather Chemical Experiment), and determine that the natural leather is absolutely dry weight;

[0023] Step 2. Weigh the natural leather accurately. This weight is used as the material basis for the subsequent process. Put the natural leather into the stainless steel drum, add 8 times of water, rotate for 45 minutes, raise the temperature to 40°C, and add 3 parts of hexavalent chromium. The treatment agent, the hexavalent chromium treatment agent is 1% sodium hydrogen sulfite, rotate for 4 hours, control the water, and wash with...

Embodiment 2

[0027] The steps of the method for solving the problem of hexavalent chromium exceeding the standard in the natural leather of Example 2 are completely consistent with those in Example 1, except that the hexavalent chromium treatment agent in step 2 is 1% gallic acid, and the hexavalent chromium detected by the national standard in step 4 is 1% gallic acid. The chromium content is 2.36 mg / kg, and the hexavalent chromium content detected by the EU standard is 0 mg / kg.

Embodiment 3

[0029] A method for solving the problem of hexavalent chromium exceeding the standard in natural leather is a dry state roller coating / spraying treatment technology, comprising the following steps:

[0030] Step 1. Take a certain amount of natural leather with hexavalent chromium exceeding the standard, and sample and detect the moisture and volatile content of the natural leather according to the industry standard (QB / T 2717-2005 Detection of Moisture and Volatile Matter in Leather Chemical Experiment), and determine that the natural leather is absolutely dry weight;

[0031] Step 2. Weigh the natural leather accurately, and this weight is used as the material basis for the subsequent process;

[0032] Step 3. Prepare a hexavalent chromium treatment agent. The hexavalent chromium treatment agent is 2 mol / L sodium bisulfite. Using the roller coating technology, the hexavalent chromium treatment agent is evenly rolled on the meat surface of the natural leather. The coating wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com