High-strength finish rolled steel bar and production method thereof

A production method and high-strength technology, applied in the field of steel materials, can solve the problems of high alloy composition and high cost of steel bars, and achieve the effects of reducing alloy cost, improving strength and simple control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

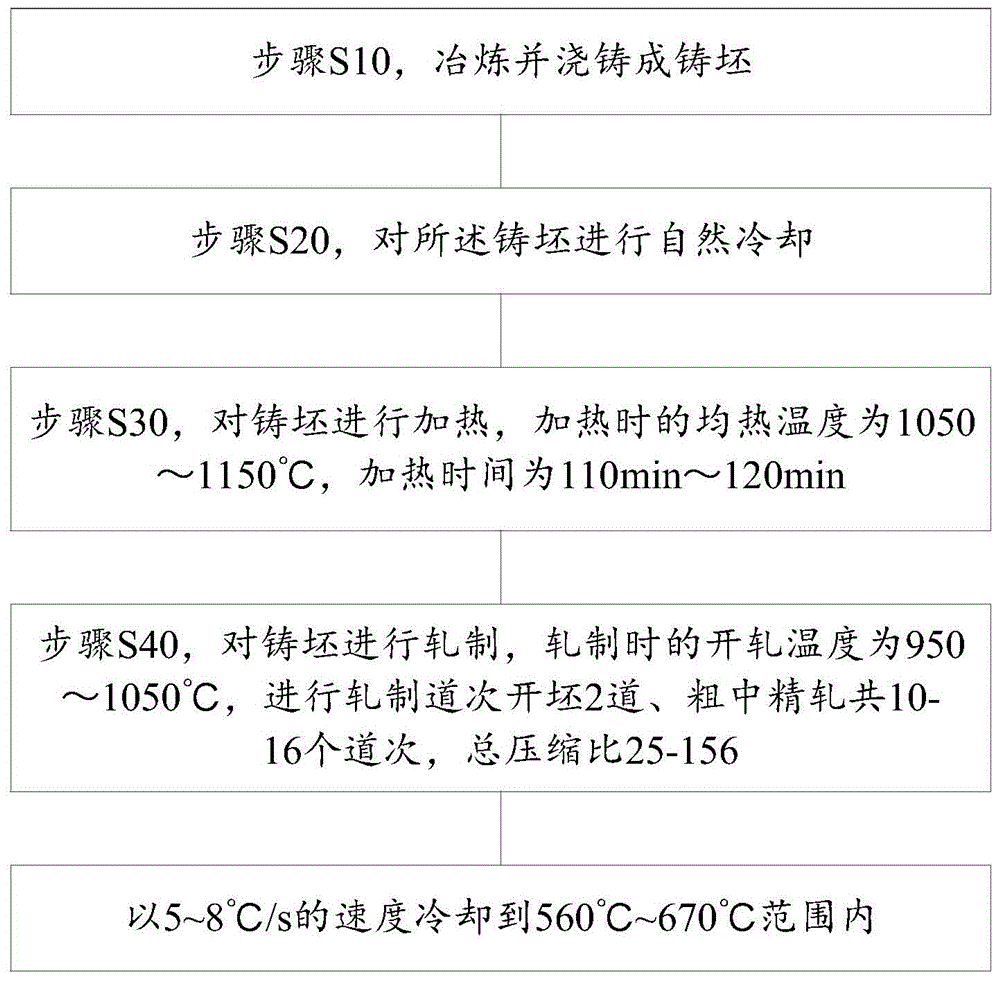

Method used

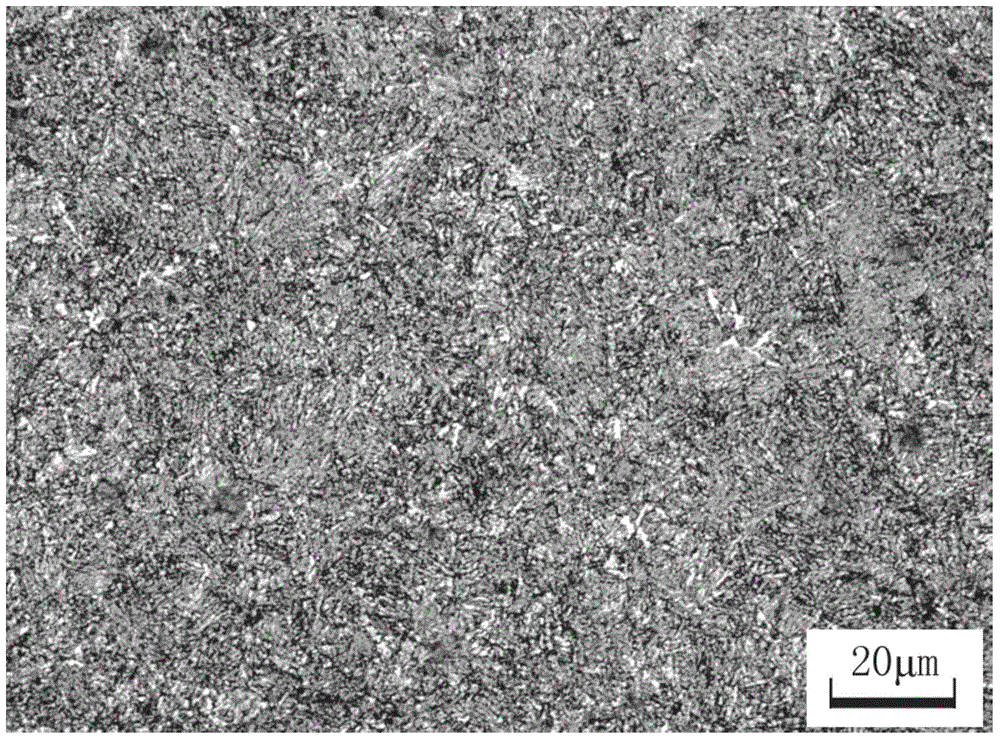

Image

Examples

Embodiment 1

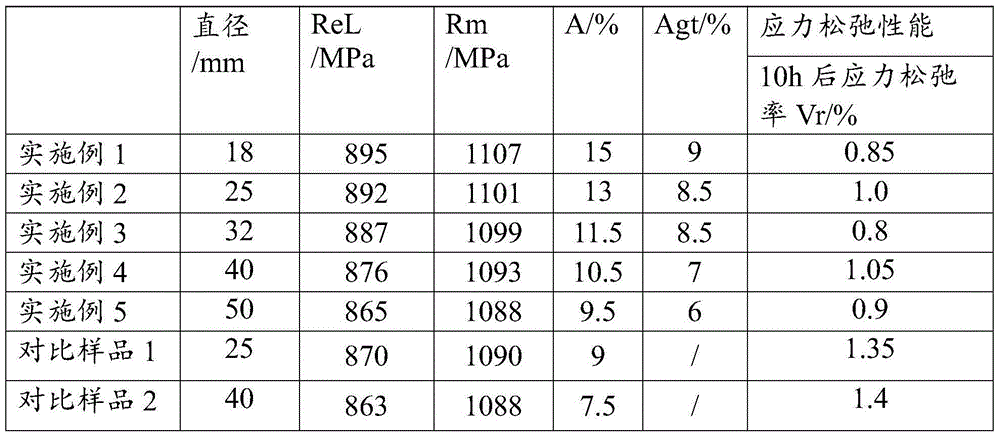

[0061] According to the requirements of steel composition, the chemical composition of molten steel is: C 0.427%, Si 0.465%, Mn 1.27%, P0.021%, S0.024%, Cr0.012%, B0.0011%; the steel is heated in the furnace to 1050°C, heat preservation for 120min to fully austenitize the steel. After being out of the furnace, the rolling temperature is 950°C, and the rolling pass is 2 passes, rough rolling and finishing rolling are 16 passes in total, and the total reduction ratio is 156. After finishing rolling, it is cooled to 670°C at a cooling rate of 5°C / s. Air-cool to room temperature after cooling.

Embodiment 2

[0063] According to the requirements of steel composition, the chemical composition of molten steel is: C 0.42%, Si 0.573%, Mn 1.4%, P0.023%, S0.017%, Cr 0.017%, B0.0015%; the steel is heated to 1050°C in the furnace , Keep warm for 120min to fully austenitize the steel. After being released from the furnace, the starting rolling temperature is 950°C, and the rolling pass is 2 passes, rough rolling and finishing rolling are 16 passes in total, and the total reduction ratio is 110. After finishing rolling, it is cooled to within 650°C at a cooling rate of 5°C / s. Put it on a cooling bed, and air-cool to room temperature after putting it on the cooling bed.

Embodiment 3

[0065] According to the requirements of steel composition, the chemical composition of molten steel is: C 0.448%, Si 0.391%, Mn 1.26%, P0.013%, S0.017%, Cr 0.011%, B0.0013%; the steel is heated to 1100°C in the furnace , Keep warm for 120min to fully austenitize the steel. After being released from the furnace, the starting rolling temperature is 1000°C, the rolling pass is 2 passes, the rough rolling is 14 passes, the total reduction ratio is 65, and the finishing rolling is cooled to 630°C at a rapid cooling rate of 7°C / s Put it on a cooling bed, and then air-cool to room temperature after putting it on the cooling bed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com