CNG (compressed natural gas) engine ignition advancer on basis of closed-loop control and method for controlling CNG engine ignition advancer

A technology of ignition advance and closed-loop control, which is applied in the direction of engine ignition, engine components, machines/engines, etc. It can solve problems such as changes, failure of the engine to achieve better performance, and inability to adapt to real-time changes in the engine ignition advance angle, so as to reduce development costs. , saving development cycle and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

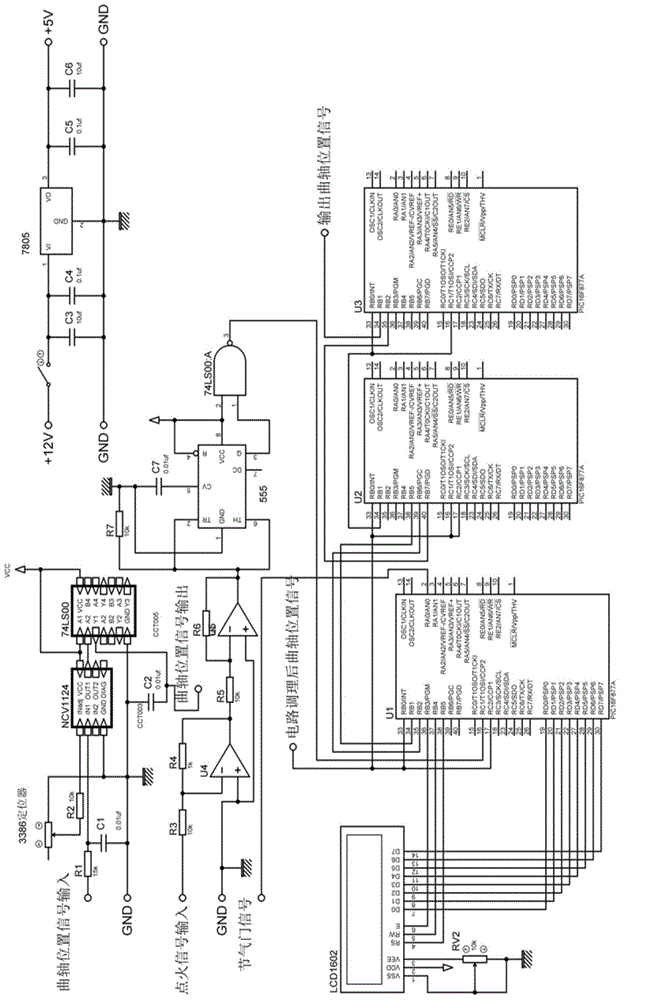

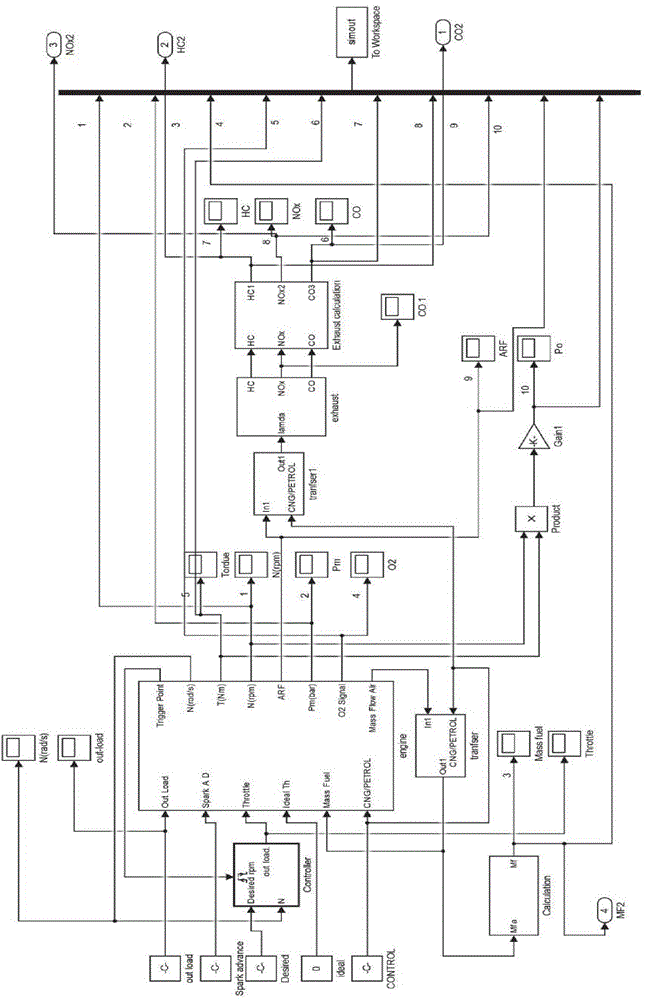

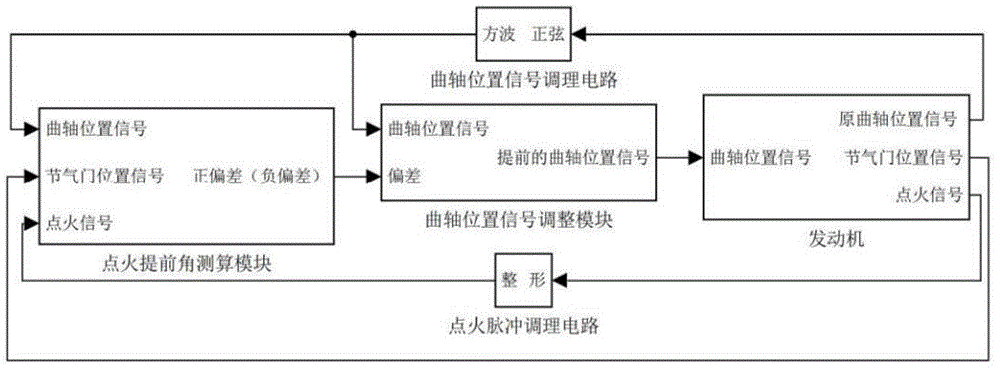

[0038] In this embodiment, a CNG engine ignition advancer based on closed-loop control is installed on a vehicle with a crankshaft position sensor. The ignition advance angle advancer includes a housing, an ignition advance angle measurement module, a crankshaft position signal adjustment module, and a crankshaft position signal conditioning module. Circuit, ignition pulse signal conditioning circuit, the shell is set in the cab of the vehicle, which is convenient to check the ignition advance angle of the current engine; ignition advance angle calculation module, crankshaft position signal adjustment module, crankshaft position signal conditioning circuit, ignition pulse signal conditioning circuit installation On the same circuit board, the circuit board is mounted in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com