Condensate-removing method and device used for refrigeration equipment transparent door and refrigeration equipment

A kind of refrigeration equipment, transparent technology, applied in the direction of household refrigeration equipment, cooling fluid circulation equipment, lighting and heating equipment, etc., can solve the problems of rising product cost, rising power consumption, and coating electric heating film coating at the same time, to achieve higher The effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

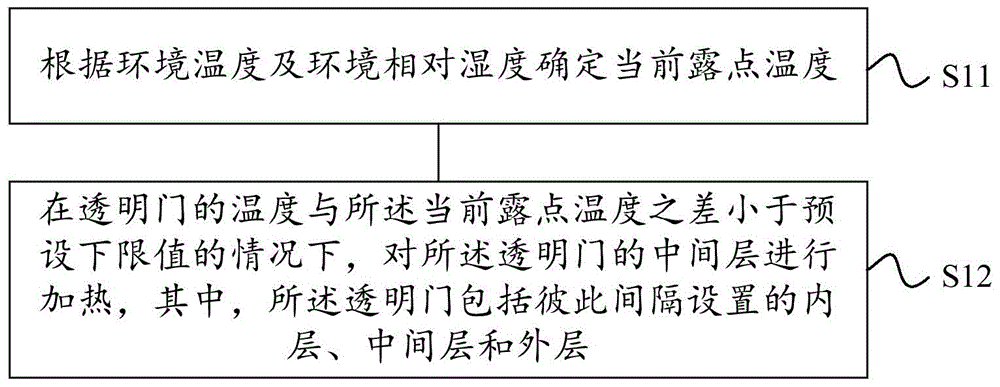

[0026] Such as figure 1 As shown, the embodiment of the present invention provides a method for removing condensation on the transparent door of the refrigeration equipment, including:

[0027] S11, determining the current dew point temperature according to the ambient temperature and the relative humidity of the environment;

[0028] S12. When the difference between the temperature of the transparent door and the current dew point temperature is less than a preset lower limit value, heating the middle layer of the transparent door, wherein the transparent door includes inner layers arranged at intervals from each other, middle layer and outer layer.

[0029] The decondensation method for the transparent door of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com